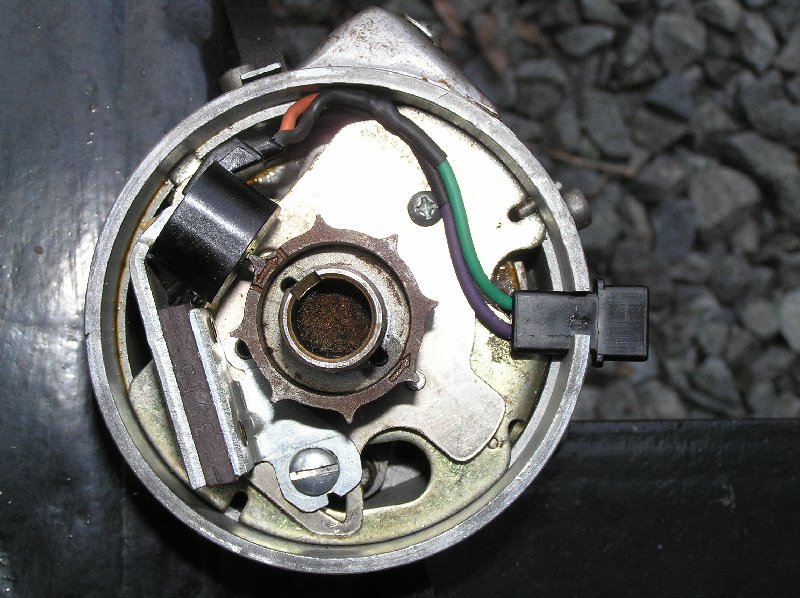

I did the HEI conversion on my 318, 87 Ramcharger today. I used an electronic distributor, A design2drive.com adaptor plate, Pertronix flamethrower coil that was listed to use, and a Standard Ignition Products HEI module. I recurved the dist to one of the MP light springs, and a light blue spring. The mechanical advance plate is a 17r (giving me 34* mechanical advance) and I did no modifications to it.

I set the timing to 16* and total mechanical timing is 45*. I DO NOT have vacuum advance hooked up B/C the factory leanburn 2bbl carb does not have a ported vacuum. I did also drill the idle mixture plugs out of the carb to adjust the idle mixture.

The issue i'm having is when its in park, it revs quicklyand runs really smoothly. When I drive it, it's a completely different story. Off idle it really sputters and hesitates to about (a guess 15-1800rpm) then picks up and runs fine. There is no spark knocking or valve pinging. It did not do this with the leanburn, just when I put the HEI on it today.

I am thinking/wondering that could it be advancing too quickly and/or is the total advance too much for it? I do also have another mechanical advance plate that is marked 15r (which would give me 30* mechanical advance). Should I put the 15r plate on and a heavier spring in place of the MP light spring? Could my problem be elsewhere?

I set the timing to 16* and total mechanical timing is 45*. I DO NOT have vacuum advance hooked up B/C the factory leanburn 2bbl carb does not have a ported vacuum. I did also drill the idle mixture plugs out of the carb to adjust the idle mixture.

The issue i'm having is when its in park, it revs quicklyand runs really smoothly. When I drive it, it's a completely different story. Off idle it really sputters and hesitates to about (a guess 15-1800rpm) then picks up and runs fine. There is no spark knocking or valve pinging. It did not do this with the leanburn, just when I put the HEI on it today.

I am thinking/wondering that could it be advancing too quickly and/or is the total advance too much for it? I do also have another mechanical advance plate that is marked 15r (which would give me 30* mechanical advance). Should I put the 15r plate on and a heavier spring in place of the MP light spring? Could my problem be elsewhere?