It would be nice if all cam manufacturers had the lobes listed in a master cam lobe list that showed not only their advertise duration and lift for each lobe & lobe family but how each lobe rise’s up and falls in small increments and beyond the .050 industry standard.true, the valves are opened and closed slower at the beginning and end of the lobes... some manufacturers have faster lobes than others....

I have over two dozen cams that I degreed so I can compare them apples to apples and have seen the difference in valve lift and close rate... some cams have had dfferent .001" - .050" ramp speed than others...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mopar Cam- how many more degrees @.006 to equal at .200?

- Thread starter Wyrmrider

- Start date

-

Keep pedaling bullshit. It’s what you do best. The sad thing is you have no clue, and you don’t learn.

How can you say that when you don't know my background????

It would be nice if all cam manufacturers had the lobes listed in a master cam lobe list that showed not only their advertise duration and lift for each lobe & lobe family but how each lobe rise’s up and falls in small increments and beyond the .050 industry standard.

That's why when I degree my cams, I take data points at .001, .010, .050, .100, .150, .200, .250, .300, .350, .400, .450, max, and then back down at the same increments.... That way, I get a better idea of the lobe profile...

Wyrmrider

Well-Known Member

Take a look where these two fit into the duration @.006 sorted list

The comp is bigger at .050 but the Howard "agressive"looks big at .200

.........................,006...020...050 ..200......cam...valve lift

3HF209300...... 256 233.... 209... 122....... 0.300 .450

Comp XE......... 256 ............ 212 ....................... .447 110lca 106 icl IC 54 ABDC

back to the original question

how may degrees at .006 (stand accelerations) do we have to add, how much IC ABDC do we have to add to get the ,200 duration of the 250-255 Mopar lobes

VOODOO.701..250.........213...................454 108LCA IC about 49ABDC

Howard .......252 229...206..126 0.316 .472 standard acceleration .904 HM2063164A

The comp is bigger at .050 but the Howard "agressive"looks big at .200

.........................,006...020...050 ..200......cam...valve lift

3HF209300...... 256 233.... 209... 122....... 0.300 .450

Comp XE......... 256 ............ 212 ....................... .447 110lca 106 icl IC 54 ABDC

back to the original question

how may degrees at .006 (stand accelerations) do we have to add, how much IC ABDC do we have to add to get the ,200 duration of the 250-255 Mopar lobes

VOODOO.701..250.........213...................454 108LCA IC about 49ABDC

Howard .......252 229...206..126 0.316 .472 standard acceleration .904 HM2063164A

yellow rose

Overnight Sensation

How can you say that when you don't know my background????

It’s easy. When you blame a cam lobe for something that isn’t true, you are pedaling BULLSHIT.

If the valve is bouncing, it’s not the lobes fault. Are you so silly to to think that say, from .100 lift to the base circle the cam designer just drops the valve at maximum acceleration? You can have a very fast closing valve and still not have the lash ramp slam the valve shut.

In fact, I have NEVER seen such a lobe. Not even on the stuff that was netting .900 plus lift. Ever. If you have valve train control issues, it’s always the usual suspects. Heavy valves. Wrong spring rate. Wrong spring pressure on the seat. Flexible pushrods (this is a big one, as most guys still think a 5/16 thin wall pushrod works for everything, but it doesn’t and guys fail to use the biggest, thickest pushrod they can get) that bend like a noodle. I’ve pulled junk down that had .080 even .100 clearance between the pushrod and the head and you can see witness marks of them rubbing, and the pushrod is still straight.

Again, the issue isn’t the lobe. It gets blamed because it’s easy, but it’s incorrect.

Again, all this nonsense started when the big springs came out. What was that...1984??? When you called a cam grinder and said I’m seeing evidence that I don’t have enough spring load and I’m going to up it from 180 on the seat to 260, they’d claim any cam that took that spring load was junk. I had a Crower cam and was killing lifters. It got better every time I upped the spring load. Crower was concerned but said it it helps them you are going the right way. My dad wants sold. He was of the school the cam was junk. So I called every cam grinder I could think of and every single one of them assured me if I bought their cam, I could run 180 on the seat and still shift at 8200. Every one of them said the Crower cam was a parts breaker. And, they all either didn’t know ****, or they were lying to sell a cam.

Either way, like a dumbass, I fixed everything except what was really failing. All the hero’s claimed my ductile iron rockers were junk. Because I’d fail a rocker, bend the pushrod, kill the lifter and knock the lobe down and fill the engine with all manner of trash.

So I bought Crane rockers. Now I was bending pushrods and killing the lifters.

So I bought Smith Brothers 7/16 .120 wall pushrods. I still have them. Never bent one of those seal clubbers. But I was STILL killing lifters. So, I was going to quit. No one had any answers nd I was tired of adding to the wall of shame in my shop. It was covered with broken parts because to this day, I doubt anyone who says they were shifting at 8000 plus back in the day and ran the same junk I couldn’t.

One morning before work, I decided I’d give it one more try, and I called Jesel. Got Wayne Jesel himself on the phone. I was going to order their $100 dollar EACH lifters and give them a shot, because that’s all that was left that was failing. Of course, Crane said their lifters weren’t the issue, it was my parts breaking, junk cam. So like I said, I have Wayne Jesel on the phone.

We go over my combo and all the details and I tell him to send me a set of his lifters. He said NO. I said why not. He said because that is massive overkill. So I said them pick me a cam that won’t kill my parts. He said there is NO SUCH THING as a cam that breaks parts. Now I getting pissed. And since I’m throwing everyone under the bus, I will name names.

Jesel told me to call Crane, and get Chase Knight on the phone. And you tell him that I said his junk lifters are failing, and HIS people should have told me that a long time ago. You tell him I said that, and if he has a problem, you call me back and I’ll deal with it. So I said what lifters? He says you should have been running their Pro Series lifters from the very beginning. They shouldn’t even make that lifter with the .750 wheel for a Chrysler.

I called Chase Knight and told him exactly what Jesel said. And that day, I had a set of Pro Series lifters in the overnight mail for less than half of what they cost. And he sent a call that to get that junk set of lifters back. And guess what? Zero lifter failures. And I used the when I was shifting at 9000 for a short time. But it was always 8500-8800 and never a failure.

So I didn’t make this up. I lived it. I learned from MY experience and Wayne Jesel. If you want to argue with Wayne Jesel then knock yourself out. You’ll continue to sound ignorant.

Wyrmrider

Well-Known Member

Aj post 2

great job as usual

we'll get to the 340 cam a little later

one step at a t ime

I'll cover ramps ,008, 006, 004 later if anyone's interested

UDHarold said his chevy voodoo lunati 268 picked up 25 hp over the comp version

how much the Mopar version IDK but more mid torque for sure-

Rumble post 13

agree 100% does Hughes have a lobe catalo??g- I have to crossrefference to Howards or to Engles for earlier cams but some don;t match- maybe Bullet at one time?

Actually yr post 14 I think it's both

UDHarold said his opening and closing at the very ends of his ramps was changed between Comp and Lunati by adding another polydine (and more in the mid and going over the top)

so that makes sense in needing less spring pressure

we want neither bounce or float but want to do it with the least spring possible

yt post 15 agree hard to find the 200 data but IC is super easy- just hit “specifications”

I just wish they had more mopar lobes and they would update their profiles on their catalog grinds.

Rumble #16 Don't you love the Lunati on line catalog where all you get is a pictur and what engine but no clue as to the cam spec!!!

Hysteric post 19 tyring to keep it simple here

but going to a Mopar gives you much more than going to a 1.6 rocker

Now on our circle track build we are maxed out on the cam so 1.6 makes sene

also if you already have your cam installed and you think you can pick up some with a rocker change

you can but by the time you buy the rockers and a B3 kit and pushrods you could have got a better cam

Hysteric 21

valve speed does increase, but where?

but if you have your fulcurm too low it increases near the nose increasing chance of float

some run this way because you get more lift- some stock class guys delibertly if they can run a cheater spring. For most adjusting your rocker height (easy with chevy) for most lift is a fools game

roller rockers without adjusting th geometry gives this effect

and if too high like the Crane “quick lift” rockers you may need a bigger spring to control bounce

Most cams are ground assuming a linear rocker effect

sorry to get off your comments most applies to all rockers it's just that roller tips really throw off what the camgrinder unually intended

post 22 what rumble says

krazy post 23 That's why a quick look at intensity is important

but if you look at two Howard grind .842 series they get less intensity by being “agressive”

The Howard mopar lobe gets “intensity” from just being a larger lifter using standard profile

great job as usual

we'll get to the 340 cam a little later

one step at a t ime

I'll cover ramps ,008, 006, 004 later if anyone's interested

UDHarold said his chevy voodoo lunati 268 picked up 25 hp over the comp version

how much the Mopar version IDK but more mid torque for sure-

Rumble post 13

agree 100% does Hughes have a lobe catalo??g- I have to crossrefference to Howards or to Engles for earlier cams but some don;t match- maybe Bullet at one time?

Actually yr post 14 I think it's both

UDHarold said his opening and closing at the very ends of his ramps was changed between Comp and Lunati by adding another polydine (and more in the mid and going over the top)

so that makes sense in needing less spring pressure

we want neither bounce or float but want to do it with the least spring possible

yt post 15 agree hard to find the 200 data but IC is super easy- just hit “specifications”

I just wish they had more mopar lobes and they would update their profiles on their catalog grinds.

Rumble #16 Don't you love the Lunati on line catalog where all you get is a pictur and what engine but no clue as to the cam spec!!!

Hysteric post 19 tyring to keep it simple here

but going to a Mopar gives you much more than going to a 1.6 rocker

Now on our circle track build we are maxed out on the cam so 1.6 makes sene

also if you already have your cam installed and you think you can pick up some with a rocker change

you can but by the time you buy the rockers and a B3 kit and pushrods you could have got a better cam

Hysteric 21

valve speed does increase, but where?

but if you have your fulcurm too low it increases near the nose increasing chance of float

some run this way because you get more lift- some stock class guys delibertly if they can run a cheater spring. For most adjusting your rocker height (easy with chevy) for most lift is a fools game

roller rockers without adjusting th geometry gives this effect

and if too high like the Crane “quick lift” rockers you may need a bigger spring to control bounce

Most cams are ground assuming a linear rocker effect

sorry to get off your comments most applies to all rockers it's just that roller tips really throw off what the camgrinder unually intended

post 22 what rumble says

krazy post 23 That's why a quick look at intensity is important

but if you look at two Howard grind .842 series they get less intensity by being “agressive”

The Howard mopar lobe gets “intensity” from just being a larger lifter using standard profile

Hughes does not. Who did and does ground Hughesengines cams is an unknown to me. Others have speculated and compared lobes profiles to more than one cam grinder.Rumble post 13

agree 100% does Hughes have a lobe catalo??g- I have to crossrefference to Howards or to Engles for earlier cams but some don;t match- maybe Bullet at one time?

LMAO, but I do like there paper catalog. IF you know what’s in it before you go on line, your in much better shape. How they get new customers with that web site is a mystery.Rumble #16 Don't you love the Lunati on line catalog where all you get is a picture and what engine but no clue as to the cam spec!!!

Competition Cams is really good for cam lobe information.

@yellow rose , relax buddy, reeeeeee laaaaaaxxx....

yellow rose

Overnight Sensation

@yellow rose , relax buddy, reeeeeee laaaaaaxxx....

I am reeeeeeeeeeeeelaaaaaaaaaxxxed. It’s just rediculous to make a claim that is rediculous and then try and argue the point.

Well ya made a hell of a post above....

Wyrmrider

Well-Known Member

Being hard on parts again

back in the 60's in the days of bad springs

when even the 30-30 Duntov got stock springs

there were two breeds of camgrinders

Those that learned from Ed Winfield and everybody else

The guy Clay Smith and Red Wilson learned from was OK too

everyone else was hard on parts

Crane was giving them the needle with his offer to "computer smooth" their lobes

btw spring surge an unseat your close just like and one way to get bounce

if you have surge big spring makes it worse or big spring with surge...whatever

back in the 60's in the days of bad springs

when even the 30-30 Duntov got stock springs

there were two breeds of camgrinders

Those that learned from Ed Winfield and everybody else

The guy Clay Smith and Red Wilson learned from was OK too

everyone else was hard on parts

Crane was giving them the needle with his offer to "computer smooth" their lobes

btw spring surge an unseat your close just like and one way to get bounce

if you have surge big spring makes it worse or big spring with surge...whatever

nm9stheham

Well-Known Member

I've been thinking for some time to somehow get a library started on this site of detailed cam profiles. But to be of any use, it needs to be:It would be nice if all cam manufacturers had the lobes listed in a master cam lobe list that showed not only their advertise duration and lift for each lobe & lobe family but how each lobe rise’s up and falls in small increments and beyond the .050 industry standard.

- highly standardized

- both readable in text and downloadable in something like a comma delimited format (for computation work)

What I don't know how to do is to be able to store and source such files on a site like this. Maybe one of the moderators could help with something like that?

BTW, I have sought this type of data a couple of times from cam cam mfr's. Even with assurances that I wanted it only for my own personal use in modeling and was not a secret agent for another cam mfr, it was not going to happen. Jones' reaction to my request was to simply stop answering my cam inquiries ... pretty rude. The Howards' reaction was "sure you can get it... buy the cam" LOL

I don’t see it as rude but just not giving away a secret for free. It’s like a head porter telling you how and what and where to work on a head. That porter has just thrown out a paycheck. Though once you have the head, if your so inclined, you could learn a lot from tearing down his work to copy it. For most people, that’s to much. For others, not so much.

If your not going to purchase your own flow bench and experiment at the possible and probable outcome of a ruined head, then you paid the porter his fee and you call it tuition.

Same with the camshafts.

If you decided on this camshaft spread sheet thread, it would be huge! Absolutely monstrous.

If your not going to purchase your own flow bench and experiment at the possible and probable outcome of a ruined head, then you paid the porter his fee and you call it tuition.

Same with the camshafts.

If you decided on this camshaft spread sheet thread, it would be huge! Absolutely monstrous.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,638

- Reaction score

- 13,874

The thing is; for most of us streeters,

who now have a handle on the SCR/DCR/Ica/ and gearing relationships, the next bigger cam from the same manufacturer, pretty much blanket-cures the whole situation, especially if you start with a longer than 3.315 stroke, cuz you don't have to give away as much low-rpm torque, to get the hi-rpm power.

So these types of data, IMO,while commendable, and very interesting to study, are mostly gonna help the 3.315 stroke engines.

For most streeters, we only have ~3 or 4 sizes of cams to choose from, say, something like; 216,223,230,237, a size being ~7 degrees. I mean the 230 I have is already pushing the limit for me, and more so for my car. And 218 is the smallest I would consider. And for optimum use, the compression ratio has to be adjusted for each one.

You can always throw a next-bigger cam into an engine, and usually get away with it one time. But if your first cam was too big, and your compression was optimized for it, then the next-smaller cam, with it's smaller Ica, is likely gonna put your engine into detonation, requiring a new lazier timing curve, and the end result is just a big disappointment.So I can definitely recognize that a smogger-teen is gonna have to be careful.

But with a 360, when in doubt between two cams,, just throw the bigger one in there with plenty of compression, and it will fly........ because the 3.58 stroke has quite a bit more Effective stroke to play with, than the 3.31s.

Would such a chart help me? Sure it would, cuz I want the biggest .050 I can get, and the biggest area under the curve, commensurate with the shortest seat to seat so I have both ends covered in my Manual-trans/3.55 combo.

But A guy with an auto-trans, just throws the next bigger TC at it and his problem is solved.

I mean, that is how I see it.

who now have a handle on the SCR/DCR/Ica/ and gearing relationships, the next bigger cam from the same manufacturer, pretty much blanket-cures the whole situation, especially if you start with a longer than 3.315 stroke, cuz you don't have to give away as much low-rpm torque, to get the hi-rpm power.

So these types of data, IMO,while commendable, and very interesting to study, are mostly gonna help the 3.315 stroke engines.

For most streeters, we only have ~3 or 4 sizes of cams to choose from, say, something like; 216,223,230,237, a size being ~7 degrees. I mean the 230 I have is already pushing the limit for me, and more so for my car. And 218 is the smallest I would consider. And for optimum use, the compression ratio has to be adjusted for each one.

You can always throw a next-bigger cam into an engine, and usually get away with it one time. But if your first cam was too big, and your compression was optimized for it, then the next-smaller cam, with it's smaller Ica, is likely gonna put your engine into detonation, requiring a new lazier timing curve, and the end result is just a big disappointment.So I can definitely recognize that a smogger-teen is gonna have to be careful.

But with a 360, when in doubt between two cams,, just throw the bigger one in there with plenty of compression, and it will fly........ because the 3.58 stroke has quite a bit more Effective stroke to play with, than the 3.31s.

Would such a chart help me? Sure it would, cuz I want the biggest .050 I can get, and the biggest area under the curve, commensurate with the shortest seat to seat so I have both ends covered in my Manual-trans/3.55 combo.

But A guy with an auto-trans, just throws the next bigger TC at it and his problem is solved.

I mean, that is how I see it.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,638

- Reaction score

- 13,874

to Wyrmride;

I love what you are doing, every single page,post, and line. It is a testament to your generosity, and helps us all get a handle on how stuff works.

To YellowRose;

I love your veracity and commitment to truth; I look forward to your every post.

To the rest of you guys on this topic;

I am a Midget, and a Dwarf,a grasshopper, compared to you experienced guys. Almost not a day goes by that I don't learn something.

But one thing I can tell you for sure;

do not take the vaccine. I'd sooner die!

I love what you are doing, every single page,post, and line. It is a testament to your generosity, and helps us all get a handle on how stuff works.

To YellowRose;

I love your veracity and commitment to truth; I look forward to your every post.

To the rest of you guys on this topic;

I am a Midget, and a Dwarf,a grasshopper, compared to you experienced guys. Almost not a day goes by that I don't learn something.

But one thing I can tell you for sure;

do not take the vaccine. I'd sooner die!

MOPAROFFICIAL

If it has tits, it's a liabilititty.

More of the 'Karl show'No, it's simple physics...

Maybe 'simple physics ' but it ain't cam physics, Karl.

They call it an asymmetrical lobe, one half is not the same as its other half, in case you forgot. Inverse flanks too. You can design a cam to be nice with closing.

Goes both ways, but im not building time bombs.

yellow rose

Overnight Sensation

More of the 'Karl show'

Maybe 'simple physics ' but it ain't cam physics, Karl.

They call it an asymmetrical lobe, one half is not the same as its other half, in case you forgot. Inverse flanks too. You can design a cam to be nice with closing.

Goes both ways, but im not building time bombs.

I tried to tell him that, but his diploma says he is so smart he never has to learn anything new. It’s shameful really. It makes people fear buy. They buy the wrong cam because they are told over and over it will break parts. It just does not happen.

nm9stheham

Well-Known Member

If you decided on this camshaft spread sheet thread, it would be huge! Absolutely monstrous.

I am willing to take data and enter data to share. It is just making it in a form that is readily downloadable for anyone to access and putting it somewhere on a website. I don't have that and ain't no webmaster; a resource is needed for that.

AJ, part of the reason to have this is to go beyond cam selection. It is for being able to work on things like valvetrain geometry and spring selection. If you are gonna be accurate in modeling those matters, they get driven by the fine details of the cam profile. I started working on calculator to compute valvetrain velocities and accelerations to try to see how worthwhile geometry corrections would be, about 2 years ago, but the lack of this detailed cam data made it not worth my time to take it to completion.

FWIW.... I ran a cam profile on a old Isky grind a week ago (not a Mopar), and the steepest part of the cam was not where I was expecting. Made me want to go back and look at my springs!

kowalski440

Well-Known Member

If anyone follows through on this data plotting, the easiest way I can visualize studying it would be overlaying graphs. The double humped crank vs cam degrees/ IV + EV events version, with several cams in the same "family" overlapped for easy comparision.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,638

- Reaction score

- 13,874

@nm9stheham thanks, I had not thought that far.

Wyrmrider

Well-Known Member

guys just some food for thought

I compared cams with a max lift of .600 w/ 1.6 rockrers from 272 to 320

I found FT with durations at .006 above lash and compared with HR @.006

many of each got 46 degrees subtracting the ,050 from the ,006 high was like 59

not perfect to get INTENSITY due to asymetrical lobes but interesting none the less

These were Mopar lobe FT

chevy lobe would have to be really agressive and even then would have a hard time keeping up with a HR

IF you take the lift limit off then the HR runs away above certain durations

Wish I could find better .200 data

I compared cams with a max lift of .600 w/ 1.6 rockrers from 272 to 320

I found FT with durations at .006 above lash and compared with HR @.006

many of each got 46 degrees subtracting the ,050 from the ,006 high was like 59

not perfect to get INTENSITY due to asymetrical lobes but interesting none the less

These were Mopar lobe FT

chevy lobe would have to be really agressive and even then would have a hard time keeping up with a HR

IF you take the lift limit off then the HR runs away above certain durations

Wish I could find better .200 data

Ummmm, AJ, could you explain this?

nm9stheham

Well-Known Member

Another use for the detailed cam data is for doing an upfront check for P-V clearance. I already have an excel spreadsheet for that but you need the detailed cam profile to make it work. It's not gonna be a substitute for checking but it would be an initial 'filter' for cam & piston combinations.

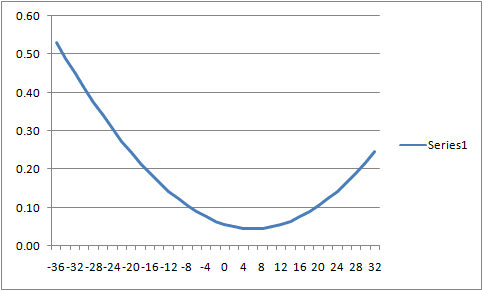

Here is an example of this with an SBM cam profile found online:

Here is an example of this with an SBM cam profile found online:

PRH

Well-Known Member

If the fastest valve action possible along with higher lift, was always better...... then a swap to a higher ratio rocker would always produce more power...... which is doesn’t.

I have done rocker swaps countless times on the dyno.

I’d say the success rate for me on that is under 50%........ with the majority of the time it showed positive results being when the motor was basically “under cammed” or running a “slower” cam.

There can be a lot of things that can impact the effectiveness of really fast valve action.

I have done hardly any dyno testing on motors with tiny cams, but my suspicion is that these are generally under cammed engines, and as such will respond over zealously with added area under the curve.

I wouldn’t expect the same results across the board in race engines that are already running a suitably sized cam for the application(which is the situation for most all the motors I’ve done rocker swaps on), especially if the valve area and flow at peak piston velocity is already sufficient to keep up with demand.

I have done rocker swaps countless times on the dyno.

I’d say the success rate for me on that is under 50%........ with the majority of the time it showed positive results being when the motor was basically “under cammed” or running a “slower” cam.

There can be a lot of things that can impact the effectiveness of really fast valve action.

I have done hardly any dyno testing on motors with tiny cams, but my suspicion is that these are generally under cammed engines, and as such will respond over zealously with added area under the curve.

I wouldn’t expect the same results across the board in race engines that are already running a suitably sized cam for the application(which is the situation for most all the motors I’ve done rocker swaps on), especially if the valve area and flow at peak piston velocity is already sufficient to keep up with demand.

yellow rose

Overnight Sensation

If the fastest valve action possible along with higher lift, was always better...... then a swap to a higher ratio rocker would always produce more power...... which is doesn’t.

I have done rocker swaps countless times on the dyno.

I’d say the success rate for me on that is under 50%........ with the majority of the time it showed positive results being when the motor was basically “under cammed” or running a “slower” cam.

There can be a lot of things that can impact the effectiveness of really fast valve action.

I have done hardly any dyno testing on motors with tiny cams, but my suspicion is that these are generally under cammed engines, and as such will respond over zealously with added area under the curve.

I wouldn’t expect the same results across the board in race engines that are already running a suitably sized cam for the application(which is the situation for most all the motors I’ve done rocker swaps on), especially if the valve area and flow at peak piston velocity is already sufficient to keep up with demand.

I’ve seen this too. If I can, I always run 1.6 rockers (or more if you can get it without killing the geometry) from the start and have the cam ground for it. I’ve never seen one lose power from going up on rocker ratio. Sometimes it just isn’t worth it.

-