I woke up even sicker (is that a word?) this morning. Tis the season. I kept on going but It slowed me down a lot. I was in a mental fog all day. I did a lot of little stuff and i probably will forget a few things I did. anyway

First I wanted to get out there and fix my brake height issue. I found a place online that listed A body manual pushrod length at 6 1/2" end to end and mine was 6 3/4" end to end which was apparently B body length. I contemplated my options, either make a 1/4" spacer for the master cylinder or cut and weld the rod. I was figuring making a spacer would end up looking like crap and taking forever to cut out then drill all the holes in 1/4" metal. I am getting more confident in my welding abilities and last night I welded some things up for the frame machine where he works. I figured since he didn't come home at lunch complaining they held out to the stress of the frame machine. This gave me the confidence to cut and weld my rod.

I cut a 1/4" out then beveled the edges so I could get good penetration. cleaned it up really good. did a few really quick light tacks just to get it straight then hit it hard. Watched the weld really penetrate and sit down in there as I was going. This is what I had when I was done welding.

Hit it with some paint and bolted it on, pedal height was PERFECT! Stepped on it a few times hard and it felt great. Everything worked out great on that little project. and I still had lots of daylight left to burn.

Next I hopped on the E brake, got it all hooked back up inside the car. seems to work good but I need the spring for it, which i don't remember it having when it came apart. either way it functions fine it just doesn't automatically return and you have to push it slightly.

Next I moved on to the fuel lines and got those all secured where I welded the new frame connectors and up in the engine bay.

Then I got the brake line by the frame connector secured nicely.

I went and attached the wipers inside since I had forgotten to do that.

got the horns and battery box all hooked up.

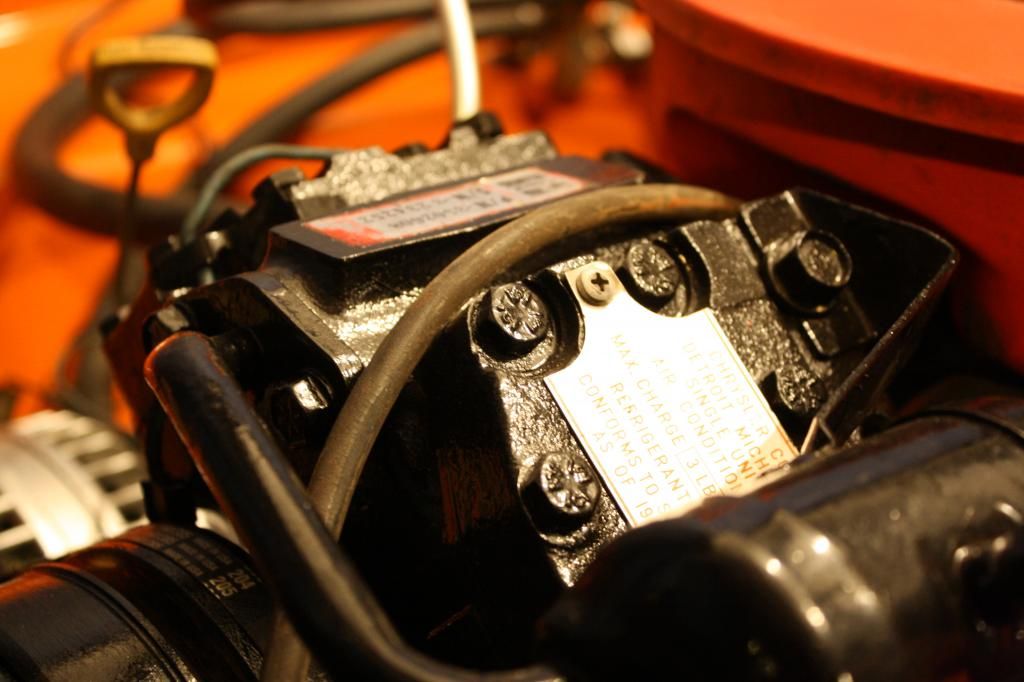

Put the wireing harness in, attached the voltage regulator and ballast resistor.

Got the back seat halfway in, I think I can get the other side in when I back the car out and get the door open all the way. I sat back there for a while to rest It was real nice back there without the passenger seat in the way. It was like a couch with wheels.

Lastly I dragged my motor towards the front of the garage. tomorrow I can hopefully get it out do some minor things to it then mock up the 4 speed on it, then put it in i guess.

Really want to have it in there as a present to myself. About 8 months into this whole thing. maybe I can drive it by this weekend???