SirDan

Well-Known Member

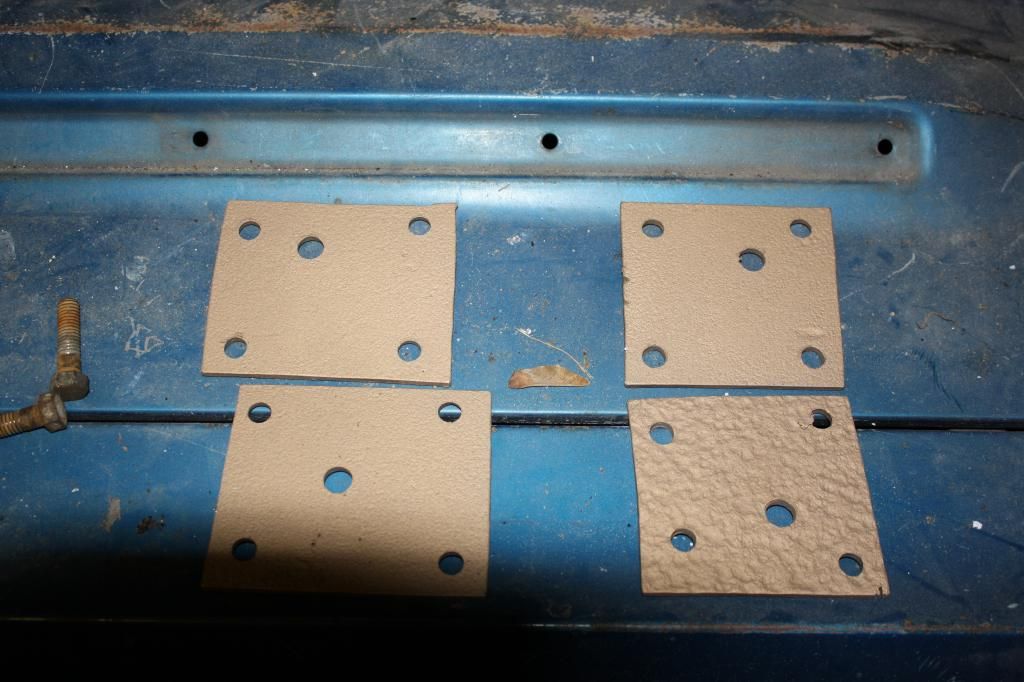

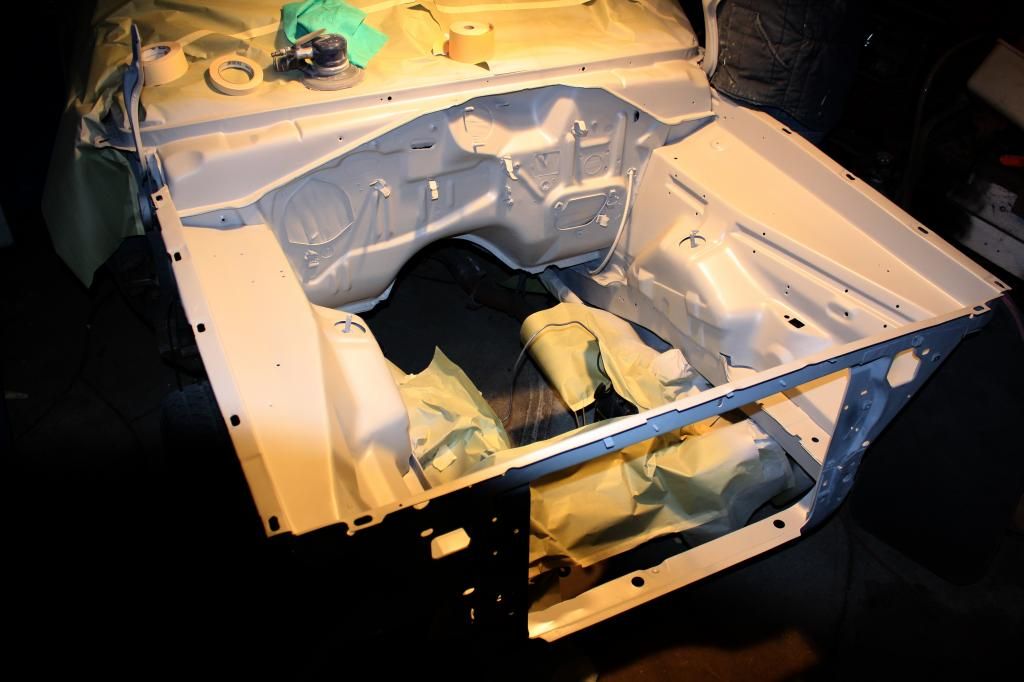

Getting back on track. got out there today and took the A body buckets out of my moms barracuda in the garage, broke a few studs but nothing I can't handle fixing. one seat track had a loose bolt that was F'd up so i had to run the tap over that. Tightened that up, drilled the holes in the floor for both seats. Sat down in one and enjoyed it for a bit. Scraped a bit of seam sealer. Then made some support brackets out of some thick steel I found in the garage. I still need to grind them blast them and drill a few places to spot weld them on. maybe tomorrow. Dad saw a bolt that was snapped off in the radiator support so i had to drill it out and tap it.

Doesn't feel like i got much done but I spent a lot of time. I figure if I've got the carpet out and I'm messing with the floor I have to set it up for the buckets. Hopefully ill get more done tomorrow.

This is the better seat

Doesn't feel like i got much done but I spent a lot of time. I figure if I've got the carpet out and I'm messing with the floor I have to set it up for the buckets. Hopefully ill get more done tomorrow.

This is the better seat