Krazed

Well-Known Member

I have some questions regarding this block. I just got it back from the machine shop and theres a few iffy parts. See pics below for additional information/details.

First: I would like to know if there's any special parts to the oil galley plugs, and such that have been missed? I took pics of rear oil galley by the distributor, as well as the rear main cap. (#5 cap) as some say theres special plugs that go in there. I just can't see where or what there is?

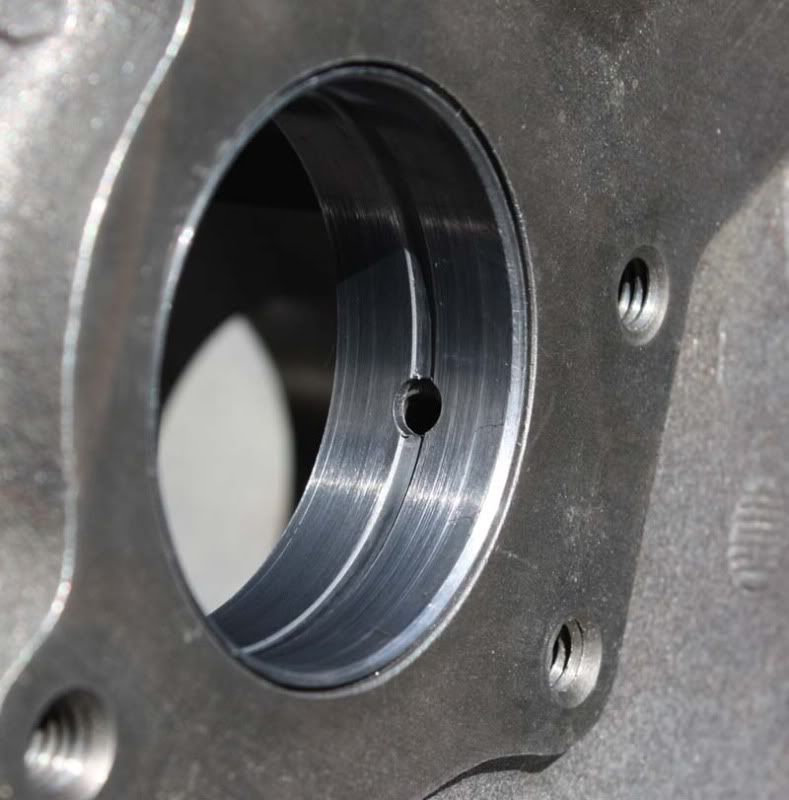

Secondly: There is a picture of a cam bearing that looks half-covered. Would this be ok to leave? Can I file it open more or should I just take it back to them to install a new cam bearing.

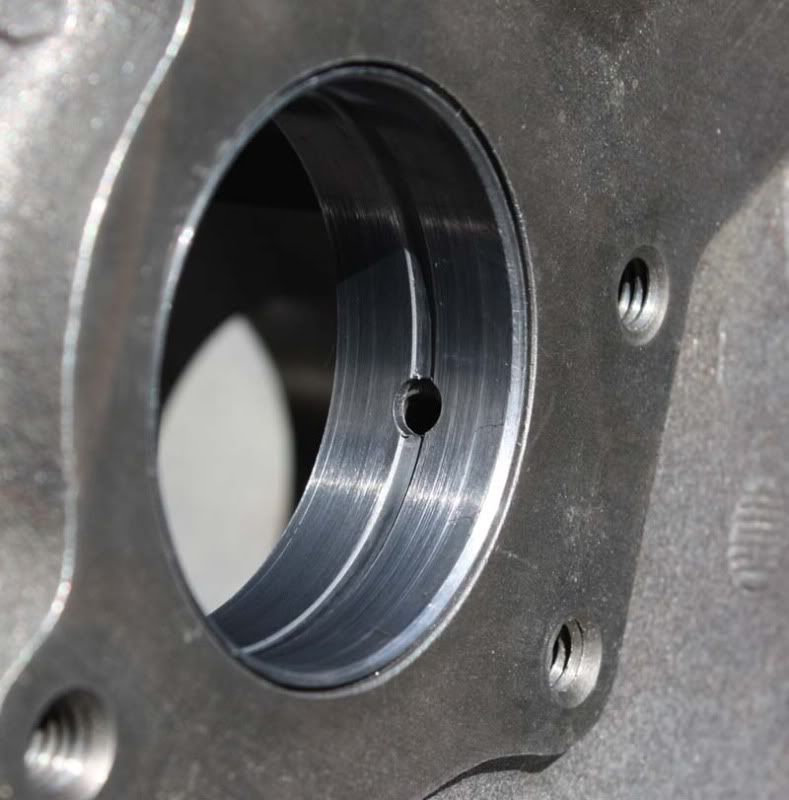

Third: The front cam bearing is very scratched. In fact, it looks like the one that was in there when I took it to their shop. A Cam bearing install tool cant really do this, can it?

Fourth : The front cam plate area, where the two small plugs are. Is it common to drill out small holes in one or both sides for oil to get through to the timing chain? I bought a new cam plate, and want to do this right as the old one burned up.

Thanks for any help! Hopefully this answeres questions for others too.

First: I would like to know if there's any special parts to the oil galley plugs, and such that have been missed? I took pics of rear oil galley by the distributor, as well as the rear main cap. (#5 cap) as some say theres special plugs that go in there. I just can't see where or what there is?

Secondly: There is a picture of a cam bearing that looks half-covered. Would this be ok to leave? Can I file it open more or should I just take it back to them to install a new cam bearing.

Third: The front cam bearing is very scratched. In fact, it looks like the one that was in there when I took it to their shop. A Cam bearing install tool cant really do this, can it?

Fourth : The front cam plate area, where the two small plugs are. Is it common to drill out small holes in one or both sides for oil to get through to the timing chain? I bought a new cam plate, and want to do this right as the old one burned up.

Thanks for any help! Hopefully this answeres questions for others too.