mopar56

Well-Known Member

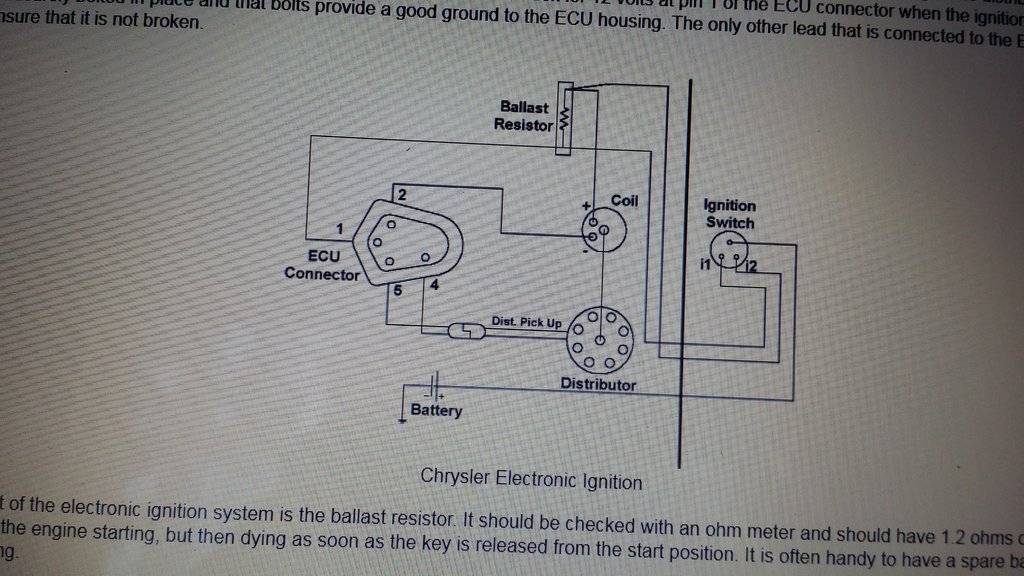

Well the kids duster is finally back together I installed a factory style 72 and up ignition system using the diagram shown but I have no spark I installed a 1980 318 from my other sons truck and used his distributor which works fine I used a new orange box and new after market wire harness and single ballast resistor now before anyone says I should use a gm hei system I DON'T put Chevrolet parts on a Dodge, EVER! And I have used Chrysler ignition systems for years and Never had a failure so this is what I'm using but I must have done something wrong during this install I'm sure it's simple I have 12v at positive and negative coil terminals with key on even though my orange box is new I have several others and have tried them all with no effect also I have some spare coils and tried those to but when I hold the coil wire to ground I have no spark what am I missing here? Oh I should add I have NOT bolted the orange box to the fender yet but I did run a jumper ground with aligator clip from the box to ground, maybe that isn't enough? Thanks