dibbons

Well-Known Member

Just going to try a different oil pan on the '65 Formula S (now 318) because the steering link wants to punch a hole in it.

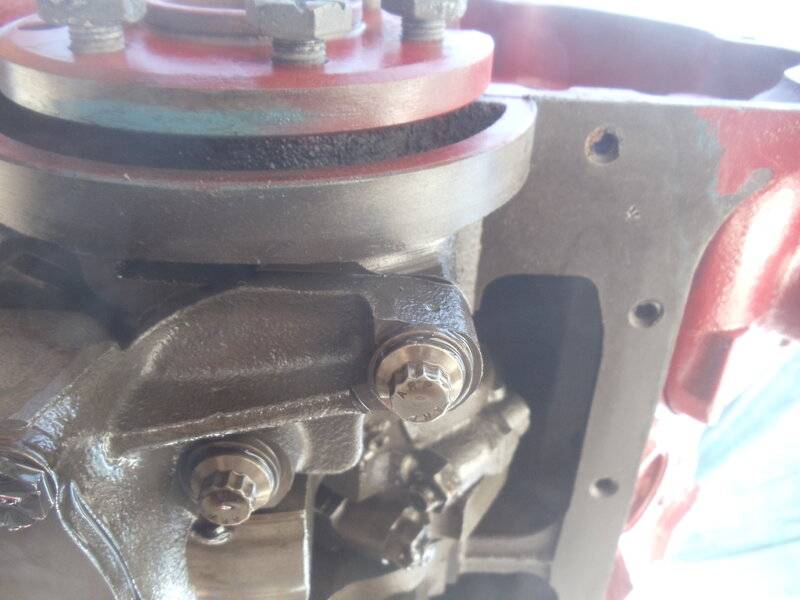

Oh, and did they really weld the rod nut to the bolt in that one photo? Yikes!