capnswanny

Active Member

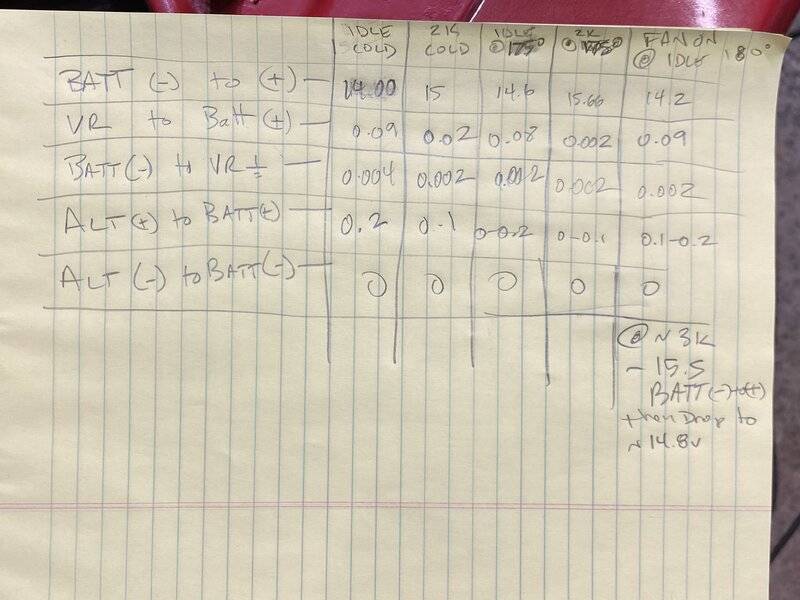

After replacing the terminal on the battery, my son and I started the car up and took a number of readings. It looks to me like it’s fixed now!?!

I think using the VR 106 may have been causing some problems, I should’ve done one thing at a time instead of applying multiple patches to the problem.

Here’s a picture of the engine bay with their original style VR installed now.

Here are the voltage readings I scrawled down with the engine running. Sorry for the crappy handwriting, I was in a hurry! ;)

Unless you see something out of place, I’m going to tidy up the wiring and go for a short drive tomorrow (with my AAA card) to see what happens!

Thanks Again for all your help!!

-Corey

I think using the VR 106 may have been causing some problems, I should’ve done one thing at a time instead of applying multiple patches to the problem.

Here’s a picture of the engine bay with their original style VR installed now.

Here are the voltage readings I scrawled down with the engine running. Sorry for the crappy handwriting, I was in a hurry! ;)

Unless you see something out of place, I’m going to tidy up the wiring and go for a short drive tomorrow (with my AAA card) to see what happens!

Thanks Again for all your help!!

-Corey