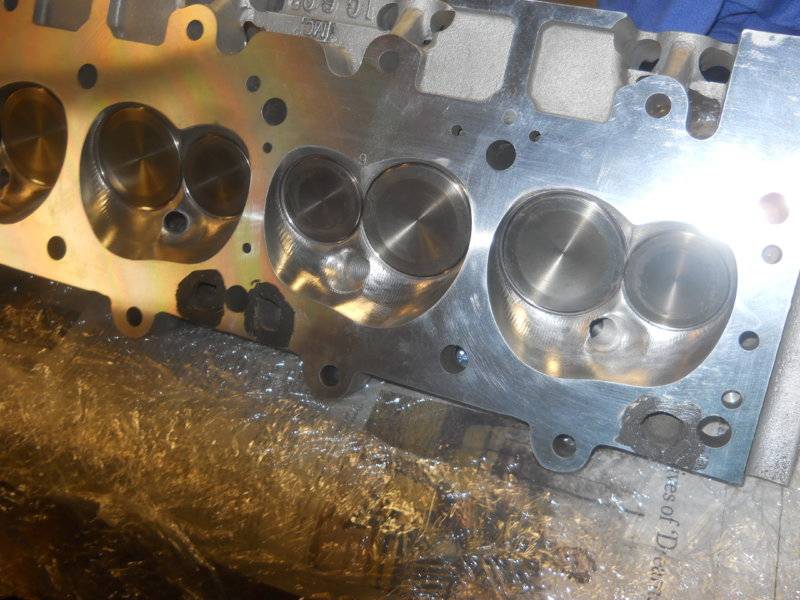

After my son fixed the Indy Heads that were machined wrong we got the heads back together We installed one on the motore and the other was set on loose to check pushrod length.

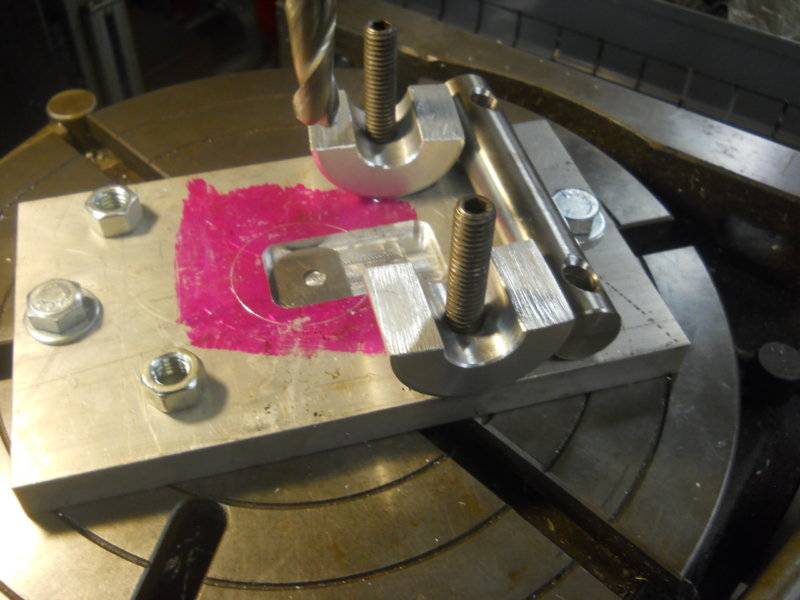

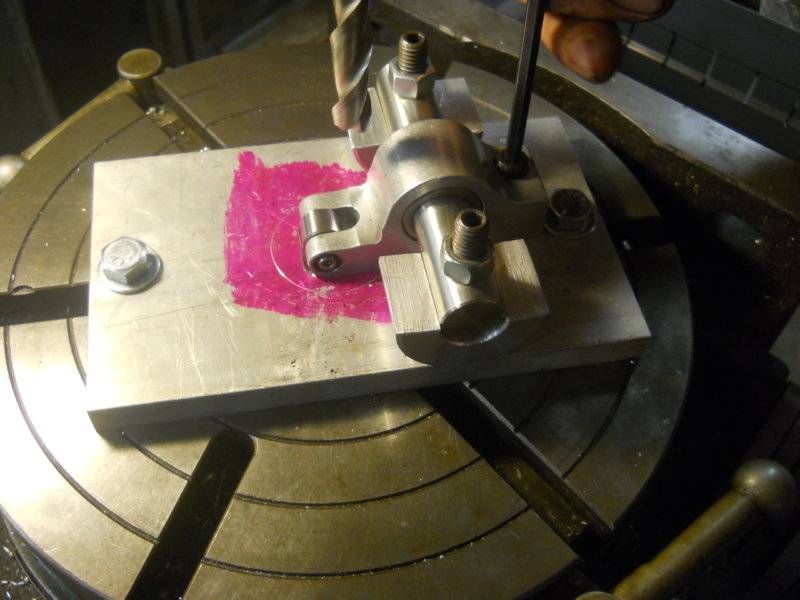

He saw the springs were hitting the rockers pretty hard but not all. He made a fixture to fit the turntable so he could cut the radius deeper. This would allow precise cutting of the same radius on all the rockers. Three fixture would have to be made.

One for the exhaust and two for the intakes due to opposite angles. He started on the Exhaust and found not one was the same depth. That is why some hit and others didn't. This was due to real poor machine set up at T&D.

Just some info I thought I woul pass on to those who are running their Rockers.

The picture below show what had to be done to correct the rockers.

He saw the springs were hitting the rockers pretty hard but not all. He made a fixture to fit the turntable so he could cut the radius deeper. This would allow precise cutting of the same radius on all the rockers. Three fixture would have to be made.

One for the exhaust and two for the intakes due to opposite angles. He started on the Exhaust and found not one was the same depth. That is why some hit and others didn't. This was due to real poor machine set up at T&D.

Just some info I thought I woul pass on to those who are running their Rockers.

The picture below show what had to be done to correct the rockers.

Last edited: