You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Proform 850 dialing it in closer

- Thread starter Cudafever

- Start date

-

E holes i couldn't tell you as i haven't had the bowls off or ever measured them yet.you could expand the time scale.

I forget, what size e-holes and HSABs ?

The HSABs are 27 all the way around. my notes say that i was going to put a 25 in????????? that would make it trend richer at the top end....Right????

Hellcat graph expanded

The rpm didn't start reading until half way thru first gear.

Mattax

Just the facts, ma'am

Weird about the rpm but bette ythan nothing.E holes i couldn't tell you as i haven't had the bowls off or ever measured them yet.

The HSABs are 27 all the way around. my notes say that i was going to put a 25 in????????? that would make it trend richer at the top end....Right????

Hellcat graph expanded

View attachment 1715785261

The rpm didn't start reading until half way thru first gear.

Yes smaller should provide less correction at the top.

It also can cause either more or less fuel to get moving when the mains are starting.

It would be good to know what size and how many e-holes are there.

Perhaps I didn't look far enough back. Is this with the Holley blocks or did I recall correctly your trying new?

Did go back to when you made a pass on primaries and it looked like it was drifting richer.

So yea I'm thinking the emuslsion may be too many holes or too big.

Interesting the AFR on those is much richer than your passes yesterday with secondaries.

I think we would have to go back to the demon thread to find the proform metering blocks and how many holes and what size.

here's the recap.

keep buying proform part to replace on the demon until i had two carbs, minuses fuel bowls. so i bought fuel bowls and now have a demon and a proform 850 carbs.

Nothing really helped until i put the Proform metering bowls on.

They are 5 e-hole block but only use 3??????????????????????

I will have to go dig it up tonight and post it up.

here's the recap.

keep buying proform part to replace on the demon until i had two carbs, minuses fuel bowls. so i bought fuel bowls and now have a demon and a proform 850 carbs.

Nothing really helped until i put the Proform metering bowls on.

They are 5 e-hole block but only use 3??????????????????????

I will have to go dig it up tonight and post it up.

Mattax

Just the facts, ma'am

Where's yer notebook?They are 5 e-hole block but only use 3??????????????????????

I'd go with a classic, proven set up before experimenting.

Two e-holes, one about fuel level and the other near the bottom of the well - depending on how deep the well is.

Each .026 to .028" dia.

Mark W has run 3 e-holes, and I think Thumper does as well, but with much smaller bleed holes. Let's see what he's posted.

Mattax

Just the facts, ma'am

Quote from Mark

2 configured like the old style cast Holley blocks always works. I use 3, but opt for smaller holes .-020-.021 range. Of course I also use different boosters...

post 15 Emulsion Tuning

Quote from Tuner.

In my experience data logging WOT AFR an irregular saw-tooth A/F trace occurs when the e-bleeds get over .028". In the AFR logs that were in the Innovate forum (do you recall?) the BG carbs with .031" well bleeds [aka e-holes] produced an erratic AFR data trace that looks like a saw-tooth. Changing the MAB from .036" to .028" helped, but changing the well bleeds to .028 flattens the AFR trace such that it looks like a lot of smoothing is applied, which was not the case, the carbs just delivered the fuel more consistently. The A/F in some logs (from carbs with oversize bleeds) exhibited not only saw-tooth but also the tendency to switch between two AFRs for a second or more, as if the jet size were changed with the flip of a switch, sometimes on a gear shift and sometimes in a single gear, rich-lean-rich, 12/1 – 14/1 – 12/1, all at WOT with the RPM rising and without moving the throttle. One I distinctly recall in the Innovate forum was a Pontiac with a 4 speed but others did it too. Changing the bleeds to the old-school Holley configuration eliminates that erratic behavior.

2 configured like the old style cast Holley blocks always works. I use 3, but opt for smaller holes .-020-.021 range. Of course I also use different boosters...

post 15 Emulsion Tuning

Quote from Tuner.

In my experience data logging WOT AFR an irregular saw-tooth A/F trace occurs when the e-bleeds get over .028". In the AFR logs that were in the Innovate forum (do you recall?) the BG carbs with .031" well bleeds [aka e-holes] produced an erratic AFR data trace that looks like a saw-tooth. Changing the MAB from .036" to .028" helped, but changing the well bleeds to .028 flattens the AFR trace such that it looks like a lot of smoothing is applied, which was not the case, the carbs just delivered the fuel more consistently. The A/F in some logs (from carbs with oversize bleeds) exhibited not only saw-tooth but also the tendency to switch between two AFRs for a second or more, as if the jet size were changed with the flip of a switch, sometimes on a gear shift and sometimes in a single gear, rich-lean-rich, 12/1 – 14/1 – 12/1, all at WOT with the RPM rising and without moving the throttle. One I distinctly recall in the Innovate forum was a Pontiac with a 4 speed but others did it too. Changing the bleeds to the old-school Holley configuration eliminates that erratic behavior.

Mattax

Just the facts, ma'am

Earlier in the thread is the graph showing what can happen with too much/many air holes in the well.Quote from Mark

2 configured like the old style cast Holley blocks always works. I use 3, but opt for smaller holes .-020-.021 range. Of course I also use different boosters...

post 15 Emulsion Tuning

Too bady Andy F didn't take the good advice provided in that thread.

Halfway measures don't work in a situation like this. When there is too much air introduced, its no longer an 'emulsion'. It doesn't act like a lower density liquid, it acts like a fluid with big air pockets and randomly spurts out fuel in different amounts and densities. And how does it flow - laminar or turbulent? Its a mess.

Way back in the beginning Tuner quotes Klaus about "two phase" liquids. The emulsion has to be a mix of fuel with tiny air bubbles for it to act as a lower density liquid.

Last edited:

Yes i need to get better at that.Where's yer notebook?

I'd go with a classic, proven set up before experimenting.

Two e-holes, one about fuel level and the other near the bottom of the well - depending on how deep the well is.

Each .026 to .028" dia.

Mark W has run 3 e-holes, and I think Thumper does as well, but with much smaller bleed holes. Let's see what he's posted.

Quote from Mark

2 configured like the old style cast Holley blocks always works. I use 3, but opt for smaller holes .-020-.021 range. Of course I also use different boosters...

post 15 Emulsion Tuning

Quote from Tuner.

In my experience data logging WOT AFR an irregular saw-tooth A/F trace occurs when the e-bleeds get over .028". In the AFR logs that were in the Innovate forum (do you recall?) the BG carbs with .031" well bleeds [aka e-holes] produced an erratic AFR data trace that looks like a saw-tooth. Changing the MAB from .036" to .028" helped, but changing the well bleeds to .028 flattens the AFR trace such that it looks like a lot of smoothing is applied, which was not the case, the carbs just delivered the fuel more consistently. The A/F in some logs (from carbs with oversize bleeds) exhibited not only saw-tooth but also the tendency to switch between two AFRs for a second or more, as if the jet size were changed with the flip of a switch, sometimes on a gear shift and sometimes in a single gear, rich-lean-rich, 12/1 – 14/1 – 12/1, all at WOT with the RPM rising and without moving the throttle. One I distinctly recall in the Innovate forum was a Pontiac with a 4 speed but others did it too. Changing the bleeds to the old-school Holley configuration eliminates that erratic behavior.

Hmmm Saw tooth, good description and mine look a lot like that one.

Spikes lean on gear change.........

ok off to find data.

tjpatte

Well-Known Member

The bleeds in my 3 hole QF850, top to bottom .027, .027 and .032. Plugged the middle and left the rest open. Moved the IFR to the bottom and reduced the jet from .039 to .031 which helped my idle AFR immensely. Need to work on cruise then should be close.

Learned a lot at Racing Fuel Systems that Mattax links to.

Learned a lot at Racing Fuel Systems that Mattax links to.

Well that is all i could find and i still don't know what size the are.........

https://www.forabodiesonly.com/mopar/attachments/high-side-ifr-png.1715380844/

https://www.forabodiesonly.com/mopar/attachments/high-side-ifr-png.1715380844/

EDIT

I have searched and searched, no one is showing what size the E-bleed size is.

on the Proform site it show HSABs at .035......My main body came with .033 and is currently at .027 HSABs

I guess the only way to know is pull a bowl and metering block and measure them.

I think my pins are 100 miles a way at my storage unit......

https://www.forabodiesonly.com/mopar/attachments/high-side-ifr-png.1715380844/

https://www.forabodiesonly.com/mopar/attachments/high-side-ifr-png.1715380844/

EDIT

I have searched and searched, no one is showing what size the E-bleed size is.

on the Proform site it show HSABs at .035......My main body came with .033 and is currently at .027 HSABs

I guess the only way to know is pull a bowl and metering block and measure them.

I think my pins are 100 miles a way at my storage unit......

Last edited:

tjpatte

Well-Known Member

Yes, it looks a mess, but I transferred it over to an excel spreadsheet.

YupI had to pin mine with really small drill bits. I basically went through the whole carb and pinned everything with a hole in it

I did it with the demon carb but not the Proform.......Maybe this winter.

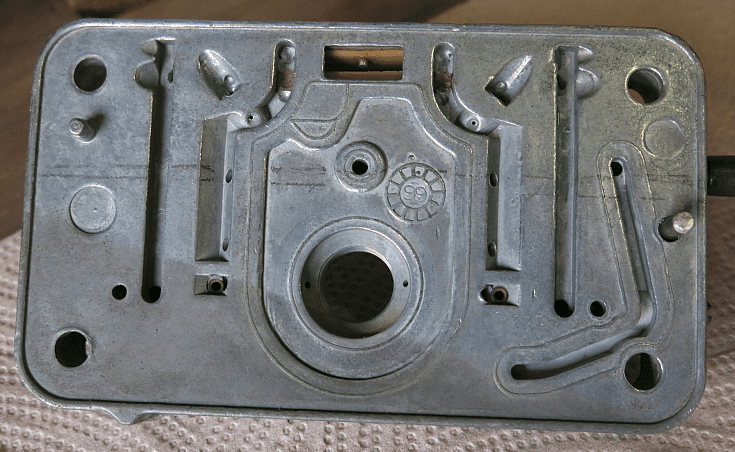

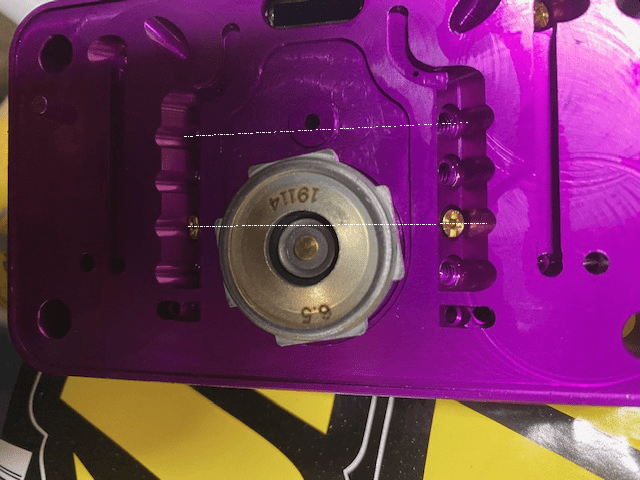

Pulled the metering block off that hasn't came off sence installed new last year.

Its not a 5 hole but a 4 hole and the brass jet is a plug and the open jet holes are pre drilled holes.

so i could plug one of the 3 remaining holes to see if it smooth out the o2 reading(Saw tooth affect)

But were do i find jet plugs this small?

Do i Plug the top hole or 2nt one down?????

I pinned the holes, but don't have any way to read/measure the pin so will have to go to work to do that, in the morning.

Its not a 5 hole but a 4 hole and the brass jet is a plug and the open jet holes are pre drilled holes.

so i could plug one of the 3 remaining holes to see if it smooth out the o2 reading(Saw tooth affect)

But were do i find jet plugs this small?

Do i Plug the top hole or 2nt one down?????

I pinned the holes, but don't have any way to read/measure the pin so will have to go to work to do that, in the morning.

Mattax

Just the facts, ma'am

The most logical approach might be to start at the top.

The top hole should just be at fuel level to start blowing some liquid up the well at beginning of pressure drop at the booster.

If the top hole is above fuel level, then plug it.

You know where the fuel level is from the sight plug or glass.

Comparing the e-hole positions with an older Holley block, it looks like the top hole and the 3rd hole down would be the ones to leave open.

I suppose if the fuel level is lower, then go for 2 & 4.

We're assume you only have the option of plugging and the factory has drilled the e-holes to something in the .026 to .028" range.

The top hole should just be at fuel level to start blowing some liquid up the well at beginning of pressure drop at the booster.

If the top hole is above fuel level, then plug it.

You know where the fuel level is from the sight plug or glass.

Comparing the e-hole positions with an older Holley block, it looks like the top hole and the 3rd hole down would be the ones to leave open.

I suppose if the fuel level is lower, then go for 2 & 4.

We're assume you only have the option of plugging and the factory has drilled the e-holes to something in the .026 to .028" range.

Last edited:

tjpatte

Well-Known Member

Believe it uses 6/32 jets, you can get them from Summit. You can order blanks and drill them yourself, or get the predrilled ones.

Quick Fuel Carburetor Idle Feed Restrictors - Free Shipping on Orders Over $99 at Summit Racing

Quick Fuel Carburetor Idle Feed Restrictors - Free Shipping on Orders Over $99 at Summit Racing

Mattax

Just the facts, ma'am

Brad H wrote

Q-850 metering blockI've had 2 sets of the QFT/Proform 4-emulsion billet blocks and their emulsion orifice sizing has been all over the place. The specs I found indicated the as-drilled e-holes are supposed to be .028"

Thanks for that.Believe it uses 6/32 jets, you can get them from Summit. You can order blanks and drill them yourself, or get the predrilled ones.

Quick Fuel Carburetor Idle Feed Restrictors - Free Shipping on Orders Over $99 at Summit Racing

I don't see any plugs.......But i guess i could just solder on up.....4 of them up.

tjpatte

Well-Known Member

Thanks for that.

I don't see any plugs.......But i guess i could just solder on up.....4 of them up.

This should be it for the blanks.

Carburetor Idle Feed Restrictors - 7-7-10qf KEYWORD - Free Shipping on Orders Over $99 at Summit Racing

Mattax

Just the facts, ma'am

Old school. Solt lead plugs. LOL.Thanks for that.

I don't see any plugs.......But i guess i could just solder on up.....4 of them up.

Funny in the 850 Thread link Tuner made the same suggestion about plugging 2 & 4 unless the fuel level is lower, the 1 &3. Obvious his posts have influenced me!

Mark mentions in this post that he'll sometimes use the very bottom e-hole in deep wells for alky and oxygenated fuels.

holley billet metering block and emulsion jet question

Doesn't seem like your situation, although if you had three bleeds restricted to .020 you could experiment with that.

McMaster Carr stocks 3/16 set screws and shipping is based on actual shipping cost.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,146

- Reaction score

- 4,153

I buy 6-32 brass set screws from Fastenal.

tjpatte

Well-Known Member

That's what I did with mine (3 hole emulsion), but I don't have the predrilled holes like his and wonder if there is anything to bottom out the set screws in his?I buy 6-32 brass set screws from Fastenal.

-

Similar threads

- Replies

- 13

- Views

- 482

- Replies

- 20

- Views

- 916

- Replies

- 11

- Views

- 478