I didn’t read all of the comments yet but I will I have another money saving suggestion. If you wipe, flip over the toilet paper, and wipe again you get twice as many wipes per roll.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re using cast iron rings?

- Thread starter Princess Valiant

- Start date

-

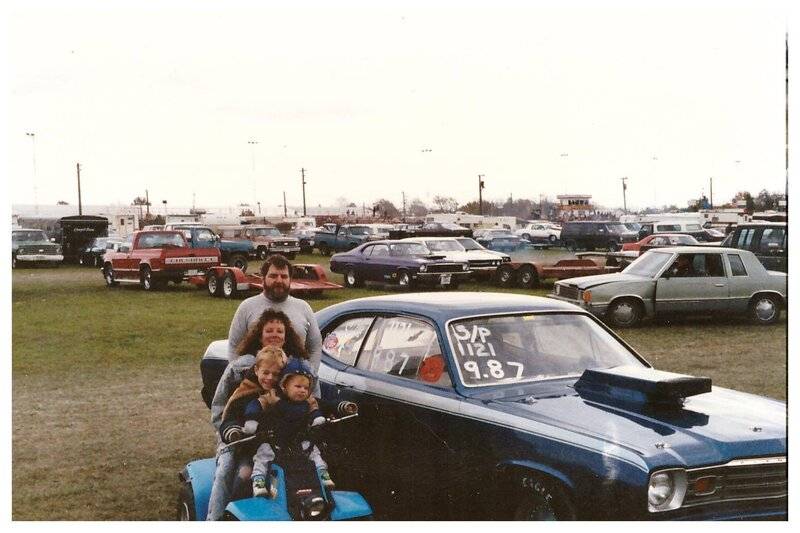

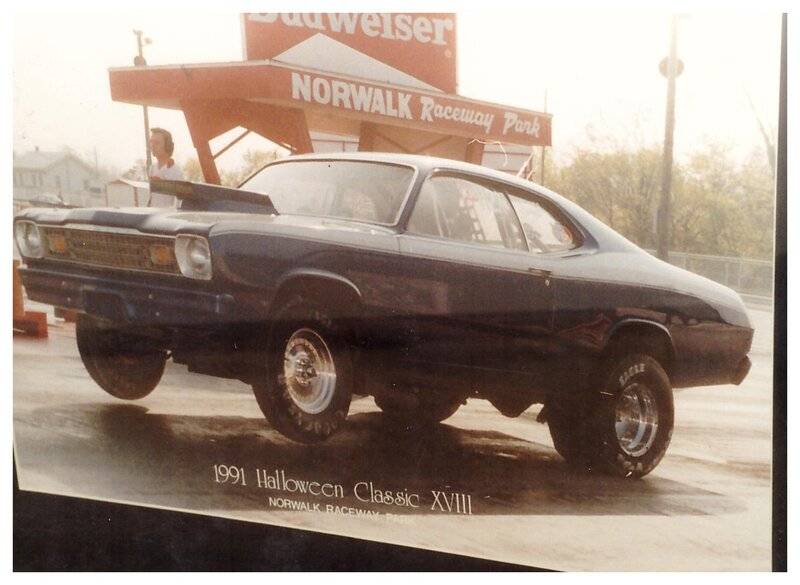

Ok I’m in the I wouldn’t do it crowd but I gotta tell you a cast ring story. Back in the late 1980’s early 1990’s I was running a 1974 (440) Duster with stock crank, stock reconditioned rods, and TRW (.030 over) pistons. I had been racing this combo for years and it needed a mid season rebuild. Lacking most of the bore measuring tools I now have I honed it at home and but new rings and bearings in it. I knew the bore was shot, at least .011-.012 but running points I had to get to the track. Well it smoked bad during Friday’s and Sundays race so Monday morning I ordered 16 cast iron rings. I was ready to rebuild it again on Wednesday when the rings came. By fridays race I was ready to go. That engine ended up running 9.82 and lasted several more years. There was no way in heck that moly rings would seal with over sized bores like that.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Like sparkling champagne..or when Tony hooks up a car battery reverse polarity.Sparkle. Like Sparkle Pony.

I made that mistake with a 340. I didn't have the foresight to use iron vs. moly and used moly. I didn't have bore measuring tools either, but, knew damn well it was crooked as ****. Put moly in anyway and within 500 miles(after teardown) top rings(moly), half were broken.Ok I’m in the I wouldn’t do it crowd but I gotta tell you a cast ring story. Back in the late 1980’s early 1990’s I was running a 1974 (440) Duster with stock crank, stock reconditioned rods, and TRW (.030 over) pistons. I had been racing this combo for years and it needed a mid season rebuild. Lacking most of the bore measuring tools I now have I honed it at home and but new rings and bearings in it. I knew the bore was shot, at least .011-.012 but running points I had to get to the track. Well it smoked bad during Friday’s and Sundays race so Monday morning I ordered 16 cast iron rings. I was ready to rebuild it again on Wednesday when the rings came. By fridays race I was ready to go. That engine ended up running 9.82 and lasted several more years. There was no way in heck that moly rings would seal with over sized bores like that. View attachment 1715952422View attachment 1715952423

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Typically ...moly rings wear themselves... while plain iron rings wear the bore.

Imo That tells you which will seat faster and be the better choice for a o.o.r cylinder/re ring job.

Imo That tells you which will seat faster and be the better choice for a o.o.r cylinder/re ring job.

Inertia

Well-Known Member

When you toss a coin, do you usually win ?

When you accidentally drop a buttered slice of ? ,.. does it land butter side up?

Ever been audited ?

These are indicators of how lucky you are .

It's a gamble, plain and simple .

When you accidentally drop a buttered slice of ? ,.. does it land butter side up?

Ever been audited ?

These are indicators of how lucky you are .

It's a gamble, plain and simple .

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Double sided coin

Uses margarine

Gets paid under the table.

LoL

Uses margarine

Gets paid under the table.

LoL

harrisonm

Well-Known Member

So I'll beat the dead horse a little more. Rings are relatively cheap. If you go to the trouble and expense to blow an engine apart and hone the cylinders, why not do it right and put in new rings. I would seriously consider checking bearing clearances with plasti-gauge while you are at it.

Oldiron440

Big blocks rule small blocks drool!

I’ve had good luck with molly rings breaking in after a hone.

I would say not as the moly is only so deep and will wear off after awhile. KimPreviously used ones?

Ya, we don’t have a crystal ball. KimThat's what I was thinking as well//but who knows what the post er did it was thinking???

I had one. Once.Ya, we don’t have a crystal ball. Kim

mopar head

DoD nuisance Alien/Squatch extermination team

That`s what happens when you have CATS!I had one. Once.

Ironracer

Gearhead

As a Carpenter for over 33 Years, and a Mopar Man almost as long, anybody that thinks they're going to do anything to your Mopar with a Carpenters level needs to leave my level up in the toolbox and go figure out what the hell they're doing somewhere else! LolWith the availability of "budget" tools available easily from outfits such as amazon, a decent dial bore gauge should be in every hobbyist engine builders tool box. The FIRST thing you do is measure for taper, AND out of round. That will tell you if your re-ring project can be successful. You do NOT check rings with a flashlight, and you damn sure dont check bores with a carpenter's level like has been suggested by your youtube hack. There is more knowledge and skill on this site ready to offer free advice and help than anywhere else.

Ironracer

Gearhead

Your plan sounds about like the plan most of us do to get an old motor running good again...Ok, so the final decision is im going to pretend I never saw that video and go with my plan A.

My plan A is to replace: rings, main bearings, rod bearings, cam bearings, timing chain, oil pump and gaskets. All of which i have on hand

I know for a fact the engine is in spec in regard to taper and cylinder measurements, I have a bore gauge and micrometers. I even have my own cam bearing tool and I've used it plenty.

I was never trying to "get cheap" with this engine, I was simply thumbing through YouTube to make sure I didn't miss anything on the prep and ran across that video. Then I started doubting myself because that particular youtuber has been building engines since long before I was born so I thought maybe he's on to something I didn't know about.

Based on the replies, I'm going to trust myself and do this engine the way I was taught in auto school.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Wrong or too rough finish will only let some oil in for some number of miles and allow the rings to eat cylinder wall faster.

If you didn't have a ridge...you will in no time if you fk up the finish and use the wrong ring.

I know... I sound overly critical. That's just me I guess when it comes to doing some things myself. You know if you paid some machine shop to do it and they did it the way some here plan on doing it you'd be pissed with what you ended up with ...so why would you do it the same shitty way yourself.. is how I look at it. hope it's not always about saving money when it comes to labor/technique. Maybe it's that "I could do the same **** myself and not pay somebody" attitude that's coming into play.lol idk

But..hey...let's not overthink this just break the glaze and throw some new whatever rings in there, pour the cheap 10w/30 stp oil into it with one quart Lucas oil treatment and let'r rip.

If you didn't have a ridge...you will in no time if you fk up the finish and use the wrong ring.

I know... I sound overly critical. That's just me I guess when it comes to doing some things myself. You know if you paid some machine shop to do it and they did it the way some here plan on doing it you'd be pissed with what you ended up with ...so why would you do it the same shitty way yourself.. is how I look at it. hope it's not always about saving money when it comes to labor/technique. Maybe it's that "I could do the same **** myself and not pay somebody" attitude that's coming into play.lol idk

But..hey...let's not overthink this just break the glaze and throw some new whatever rings in there, pour the cheap 10w/30 stp oil into it with one quart Lucas oil treatment and let'r rip.

Based on the replies, I'm going to share where I got this idea. I might have got the wrong impression or maybe that is what he meant.

I was personally taught in auto school to replace rings, nobody never even suggested such a thing except this video. my engine hardly has any ridge and ran before taken apart but is an original 74 engine that was taken apart for other issues and is intended to be overhauled stock...

That is the kind of engine I always looked for. But I would torque down a torque plate, and the main caps to spec and, using a good hone (Sunnen in my case) to just almost clean up the "waves" at the top of the cylinder when the piston reverses course. Good file to fit rings and you should be golden. Or do the best you can with a normal hone and get the OEM rings from replicaracer43 see post #17, they are quality rings. As a matter of fact, I picked up an almost new looking 273 short block this summer to do this very thing.

Ironracer

Gearhead

I Hone to what the Ring Manufacturer Specs... Master Engine Guy? Heck No! But follow the instructions and recommended SpecsWrong or too rough finish will only let some oil in for some number of miles and allow the rings to eat cylinder wall faster.

If you didn't have a ridge...you will in no time if you fk up the finish and use the wrong ring.

I know... I sound overly critical. That's just me I guess when it comes to doing some things myself. You know if you paid some machine shop to do it and they did it the way some here plan on doing it you'd be pissed with what you ended up with ...so why would you do it the same shitty way yourself.. is how I look at it. hope it's not always about saving money when it comes to labor/technique. Maybe it's that "I could do the same **** myself and not pay somebody" attitude that's coming into play.lol idk

But..hey...let's not overthink this just break the glaze and throw some new whatever rings in there, pour the cheap 10w/30 stp oil into it with one quart Lucas oil treatment and let'r rip.

That is the kind of engine I always looked for. But I would torque down a torque plate, and the main caps to spec and, using a good hone (Sunnen in my case) to just almost clean up the "waves" at the top of the cylinder when the piston reverses course. Good file to fit rings and you should be golden. Or do the best you can with a normal hone and get the OEM rings from replicaracer43 see post #17, they are quality rings. As a matter of fact, I picked up an almost new looking 273 short block this summer to do this very thing.

Mmmmm torque plates. In my almost 47 years of racing I’ve had one block (my R3 block) that has ever had a torque plate bolted to it. And I think I’ve had some pretty good running engines.

Ironracer

Gearhead

I've seen pics of Yer Mills Kicking the Dust Up! Literally lolMmmmm torque plates. In my almost 47 years of racing I’ve had one block (my R3 block) that has ever had a torque plate bolted to it. And I think I’ve had some pretty good running engines.

I've had some pretty decent Street Motors and I know the MP book recommends those torque plates I've just never had the money to do it besides that half the machine shops around here probably got no clue what the hell that was most of them didn't have them for Chrysler 30 years ago here.....

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,245

- Reaction score

- 12,242

My experience has been that if you check, say, 10 random 360 blocks, you might normally find 2 that show some level of distortion with the plate bolted on. How much is another discussion. Now, certain blocks from other manufacturers can be more or less sensitive too it also. But as a guy that gets paid to use them, I typically only do it if the customer requests it. Take that for what its worth.Mmmmm torque plates. In my almost 47 years of racing I’ve had one block (my R3 block) that has ever had a torque plate bolted to it. And I think I’ve had some pretty good running engines.

-

Similar threads

- Locked

- Replies

- 4

- Views

- 552

- Replies

- 3

- Views

- 735

- Replies

- 16

- Views

- 349

- Replies

- 13

- Views

- 574