You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing spark plugs from a body

- Thread starter BIG-B-Barracuda

- Start date

-

mguner

How many is too many?

Custom wrench and or hole saw. I have done both. #3 on the 400 Magnum in my 72 Charger is a total ***** to get out even on a lift.

1968hemidart

MOPAR CHARLIE

If you bought the correct A-BODY BIG BLOCK HEADERS from SCHUMAKER CREATIVE SERVICES, THEY ARE THE GREATEST SET OF HEADERS THAT FIT THE CAR, GREAT ACCESS TO SPARK PLUGS, THEY ARE UNDER CHASSIS HEADERS, YOU CAN INSTALL THEM WITH THE ENGINE INSTALLED, CLEARS STARTER ( MINI STARTER 1996 DODGE RAM 1500 ) AND THEY ARE MADE TO CLEAR THE TORSION BARS.

THESE ARE THE GREATEST PART FOR US A-BODY ( MOPAR ) LOVERS, AND BE SURE YOU ORDER THE BIG BLOCK CONVERSION MOUNTS FOR YOUR DART, DUSTER, DEMON, VALIANT, EARLY BARRACUDA, DART SPORT, FLEATHER DUSTER

MOPAR CHARLIE

THESE ARE THE GREATEST PART FOR US A-BODY ( MOPAR ) LOVERS, AND BE SURE YOU ORDER THE BIG BLOCK CONVERSION MOUNTS FOR YOUR DART, DUSTER, DEMON, VALIANT, EARLY BARRACUDA, DART SPORT, FLEATHER DUSTER

MOPAR CHARLIE

I've had an original 383 Formula S 68 Barracuda for 30 years. I just remove the spark plugs from underneath the car. Not bad at all. Never needed a 440 but have one, just in case.

MoparsRule

Well-Known Member

Had the same problem with my 1969 440 Cuda. Ended up purchasing a spark plug socket from Summit (Summit part number POW-POW301155) and taking the plug out from under the car!

Ok... those are badass!

buck351

Well-Known Member

Usually take the plugs out of my 67 GTS from the top. Yes it is easier from the bottom on the passenger side but doable from the top. Driver's side is easy. Stock manifolds. Got the car when it was 1.5 years old.

BIG-B-Barracuda

Well-Known Member

ENDED UP TAKING off the passenger wheel and found a opening on the k member (FRONT) and reached alllllllll the way in there wound up removing with a long wrench and the tips of my fingers.

thanks guys.... this is/WAS a hassle!

i think my passenger mount might be WORN that's why it is so hard on the passenger side & so close to fender well.

thanks guys.... this is/WAS a hassle!

i think my passenger mount might be WORN that's why it is so hard on the passenger side & so close to fender well.

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,896

- Reaction score

- 3,728

Rather than use a hole saw. Use a hole punch. Much cleaner. Less chance of an accident.

68 fish 520 stroker.TTI 2" headers edelbrock RPM heads. try 5/8 socket with 13/16" hex end with 13/16"Ring spanner- baby steps-once loosened,wind out by hand or rubber hose over plug end, cold motor unless into pain!!lol number 6 is hardest!

DrCharles

Well-Known Member

I've been gradually putting together my '72 Dart with a 451 low-deck, AR Engineering motor plate, and Hedman B-body headers, and re-learned today how much fun that #6 plug is. As someone else posted above, a very awkward reach with a 13/16" wrench from underneath and fingertips on the plug itself is about the only way. All the others are relatively easy with the wrench, and I only needed a socket for #5.

I did study the inner fender for a while, considering breaking out the hole saw, but had some trouble deciding where to cut (how to line up accurately with the axis of the plug?). What diameter hole works the best? Just big enough to slide a 13/16" socket through, or a bit larger to allow the use of boot pliers...

I did study the inner fender for a while, considering breaking out the hole saw, but had some trouble deciding where to cut (how to line up accurately with the axis of the plug?). What diameter hole works the best? Just big enough to slide a 13/16" socket through, or a bit larger to allow the use of boot pliers...

My cars have headers and my big blocks are in B bodies.. but this is what I use. http://www.compperformancegroupstores.com/store/graphics/00000004/400-POW301150.jpg

mopar65

Well-Known Member

I used I think a 1-3/4 hole saw on my 73 440 dart. I have a pick of it n this site some ware. Let me see if I can find itI've been gradually putting together my '72 Dart with a 451 low-deck, AR Engineering motor plate, and Hedman B-body headers, and re-learned today how much fun that #6 plug is. As someone else posted above, a very awkward reach with a 13/16" wrench from underneath and fingertips on the plug itself is about the only way. All the others are relatively easy with the wrench, and I only needed a socket for #5.

I did study the inner fender for a while, considering breaking out the hole saw, but had some trouble deciding where to cut (how to line up accurately with the axis of the plug?). What diameter hole works the best? Just big enough to slide a 13/16" socket through, or a bit larger to allow the use of boot pliers...

I have a 74 dart with the Schumacher kit and I have to wrench them out on the pass side. Next time the engine is out I am going to drill holes in the fender wells.

famous bob

mopar misfit

you ain`t having fun till you change them w/ raised port heads ! hole on #6 is about mandatory. problems w/ the other side too.I have a 74 dart with the Schumacher kit and I have to wrench them out on the pass side. Next time the engine is out I am going to drill holes in the fender wells.

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,896

- Reaction score

- 3,728

What diameter hole works the best? Just big enough to slide a 13/16" socket through, or a bit larger to allow the use of boot pliers...

Leave yourself some leeway. I think I used 1.25 or 1.5"

mopar65

Well-Known Member

Leave yourself some leeway. I think I used 1.25 or 1.5"

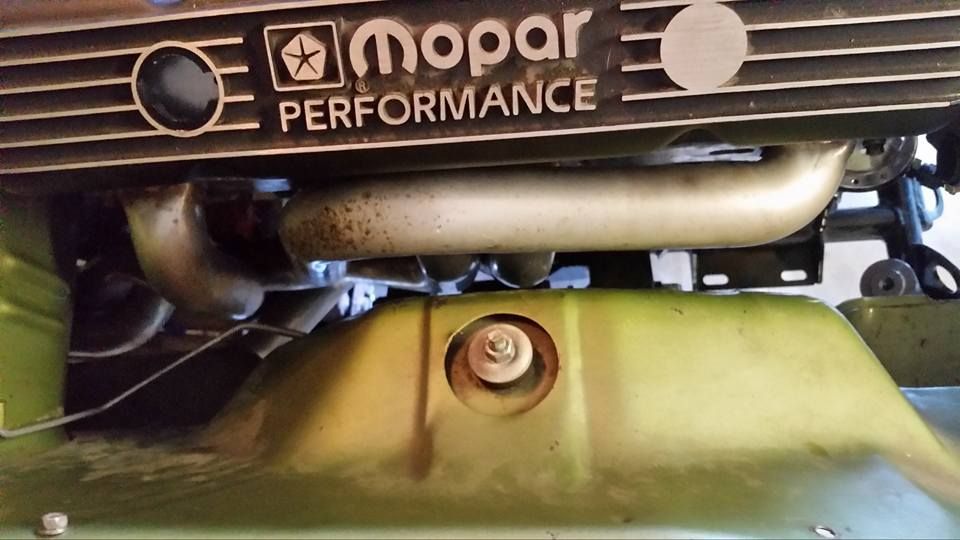

Ok here is a pic of the hole.

mopar65

Well-Known Member

Also if you have straight plugs I would move the hole over about a half inch to the right

DrCharles

Well-Known Member

Thanks, that's just what I needed. I do have straight plugs - no way angle plugs would work with some of the B-body header tubes.

I may try drilling one or two small (1/8") holes first and see where the drill bit lines up before making the big one.

I may try drilling one or two small (1/8") holes first and see where the drill bit lines up before making the big one.

mopar65

Well-Known Member

Not a problem hope it help. When I Frist drilled that hole I was runing a 906 headed 440 with the 2 inch TTI headers. I was off on the hole I think about a half inch. Because when I installed the Indy EZ heads with the angled spark plugs and the same headers the hole worked perfect. With the 906 heads It worked great useing a 3/8 extsion with wobble end. You got any pics of your car ?

DrCharles

Well-Known Member

You got any pics of your car?

Here's a couple of the right hand side early in the build... you can see access to #6 is pretty restricted, to put it mildly. I hadn't even tried to put the plugs in at that point.These are the 1-3/4" Hedman 78030 (B-body) headers, that only took a couple of very minimal dings. Available new for a mere $185

zac_F71

Well-Known Member

DrCharles

Well-Known Member

Yeah, it took me a good 20 minutes just to do #6 also!

Those 2" TTI's have a lot more inner fender clearance than my Hedman 1-3/4's. Is your engine in the stock position? How tight does it get down by the bellhousing & torsion bar?

Those 2" TTI's have a lot more inner fender clearance than my Hedman 1-3/4's. Is your engine in the stock position? How tight does it get down by the bellhousing & torsion bar?

undercoverAbody

New Member

Can you show me pics of this??A hole saw will do it.... then get a rubber plug for the hole....

On my 71 cuda with the 440 in it, had to use an open end wrench on numbers 4 and i think 2.....

Maybe un olt the motor mount and jack the engine up some?

ragtopfury

Well-Known Member

Nope. That was in the late '80s. That car is beyond long gone. Guy I sold it to back then disappeared. All I have is a pic of the car hanging on the garage wall..

DrCharles

Well-Known Member

I would recommend a metal hole plug. I tried a plastic plug and it quickly melted and fell out.

-

Similar threads

- Replies

- 3

- Views

- 419

- Replies

- 71

- Views

- 4K

- Replies

- 0

- Views

- 187