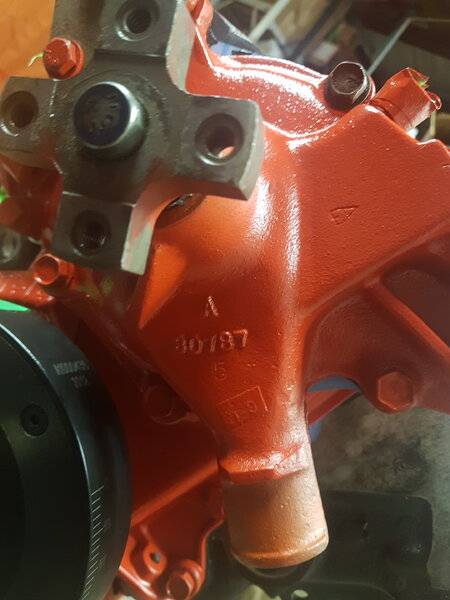

Spoke with Trickflow tech, but havent heard anything back yet about balancer fit. I got needed hardware from @Oldmanmopar , @physixx and @CFD244 and proceeded forward with timing cover, nos water pump(6 vane)and oil pan.

Skim coat of Ultrablack went on block side and on cover side. Put the cover on loosely so I could center it on the TF balancer. I was able to get the balancer on far enough to center tc cover. Got a grade 8 3/4" bolt and thick washers from Bolts Plus cheap. Using it as a puller. Bolt is 3" long.

RTV'd all bolts for waterpump and TC cover, EXCEPT the ones holding the alt bracket. Brackets gotta come off for cleanup and paint.

I had a few op gaskets to choose from, but I ended up using MP P4007572, it's a discontinued "reusable" one, we shall see.

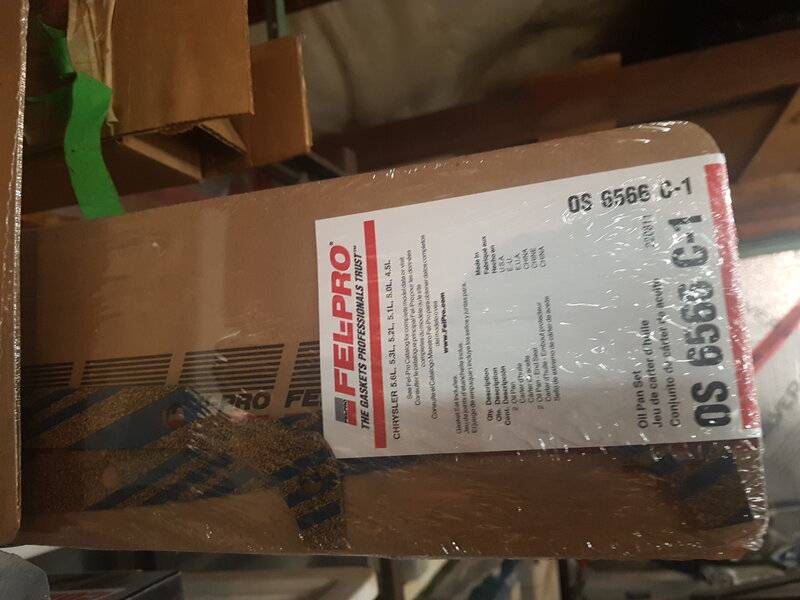

No RTV on sides, a thin skim coat on rear main, and on front timing cover. And a healthy dab where the side pieces were trimmed. End seals got a thin coat pan side and cover side with tits pulled thru. MP kit didnt come with end seals with tits, I had to order Felpro OS6566 and it comes with cork sides....

Everything is all torqued, it's now bagged and on to the heads, uh oh....

Thanks for watching.

Skim coat of Ultrablack went on block side and on cover side. Put the cover on loosely so I could center it on the TF balancer. I was able to get the balancer on far enough to center tc cover. Got a grade 8 3/4" bolt and thick washers from Bolts Plus cheap. Using it as a puller. Bolt is 3" long.

RTV'd all bolts for waterpump and TC cover, EXCEPT the ones holding the alt bracket. Brackets gotta come off for cleanup and paint.

I had a few op gaskets to choose from, but I ended up using MP P4007572, it's a discontinued "reusable" one, we shall see.

No RTV on sides, a thin skim coat on rear main, and on front timing cover. And a healthy dab where the side pieces were trimmed. End seals got a thin coat pan side and cover side with tits pulled thru. MP kit didnt come with end seals with tits, I had to order Felpro OS6566 and it comes with cork sides....

Everything is all torqued, it's now bagged and on to the heads, uh oh....

Thanks for watching.