4spdragtop

Well-Known Member

I'll crunch the new numbers and see, thanks for L2316 link.

Yeah altho the pistons are raised slightly .030" outta the hole, I wouldnt call them domes like Commandos had.

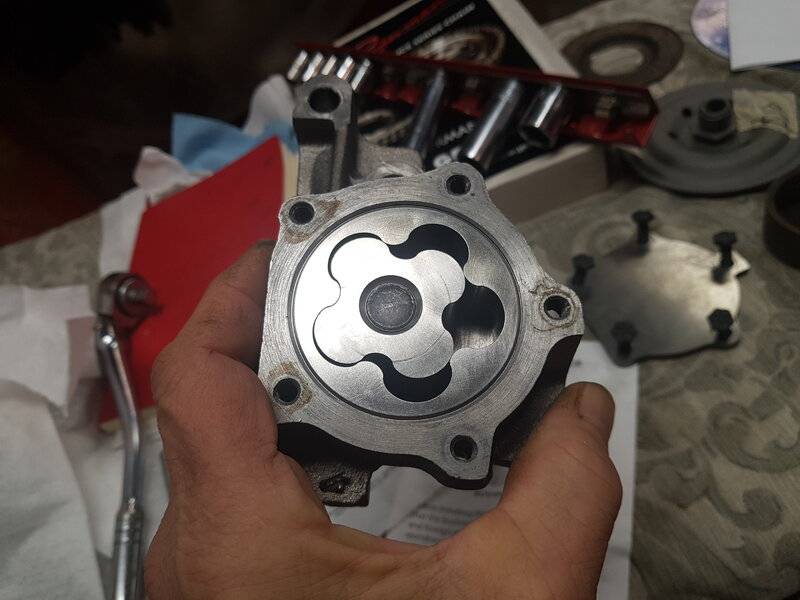

Took new Melling M72 apart and checked specs. All were good.

I'll paste a link below I found on an in depth look at the M72.

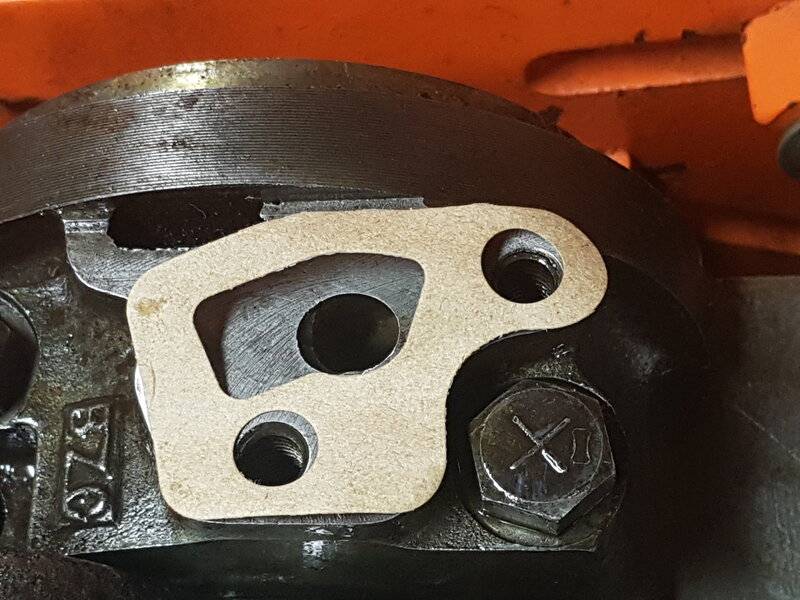

I realized I got the wrong damn MP spring kit....#P4286571 is for BB..

I need P3690944. No big deal $6/kit dealership will have tomorrow.

Sucks the downtime, could had it mounted. I'll read thru more of the link as he does some cleanup on inlet and outlet wells of the pump.

Thanks

Melling M72 Oil Pump High Pressure Conversion and Blueprinting - Poly318.com

Yeah altho the pistons are raised slightly .030" outta the hole, I wouldnt call them domes like Commandos had.

Took new Melling M72 apart and checked specs. All were good.

I'll paste a link below I found on an in depth look at the M72.

I realized I got the wrong damn MP spring kit....#P4286571 is for BB..

I need P3690944. No big deal $6/kit dealership will have tomorrow.

Sucks the downtime, could had it mounted. I'll read thru more of the link as he does some cleanup on inlet and outlet wells of the pump.

Thanks

Melling M72 Oil Pump High Pressure Conversion and Blueprinting - Poly318.com

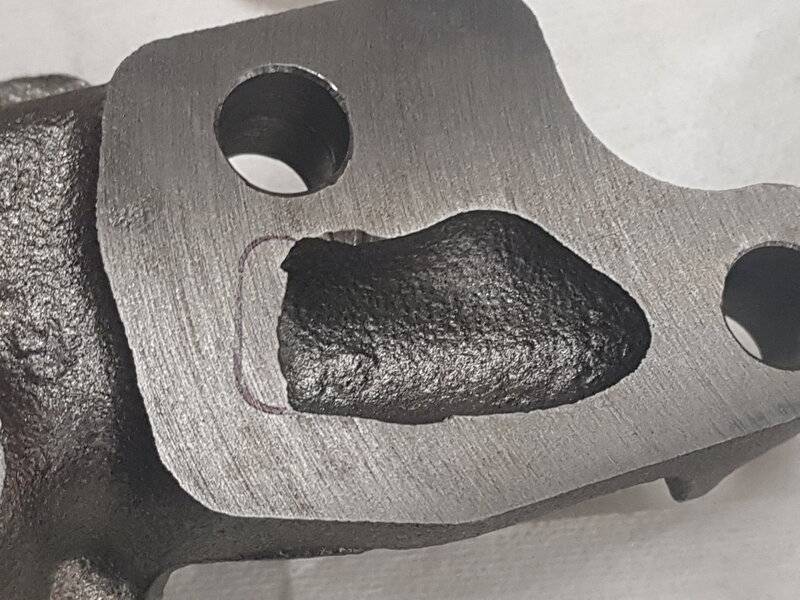

Do these numbers help? Piston head volume says +7.5 cc's. That would be plugged into the equation as -7.5 as it reduces combustion chamber volume. I would think that it takes the dome, and the reliefs into account??

[/URL][/URL]

Those aren't technically domed pistons. They're flat tops, with valve reliefs and an obvious bevel around the top edge. The 7.5 cc's should take the valve reliefs, recessed circle in the middle, and perimeter bevel all into account. I could be wrong, but I believe you'd enter the 7.5 as a positive number since it's added volume. The amount that the flat piston surface is above the deck should be entered as a negative number. You did it right in the calculator posted in post #46. Just adjust the piston volume to 7.5 instead of 8 - which won't move the needle much.

If you're deck height is actually -0.030", you're going to want a thicker head gasket than 0.039".