Archeryguy02

Well-Known Member

I recently purchased some Mancini 1.5 roller rockers for my bracket car, link below.

Mancini Racing Aluminum Roller Rocker Arm Kit

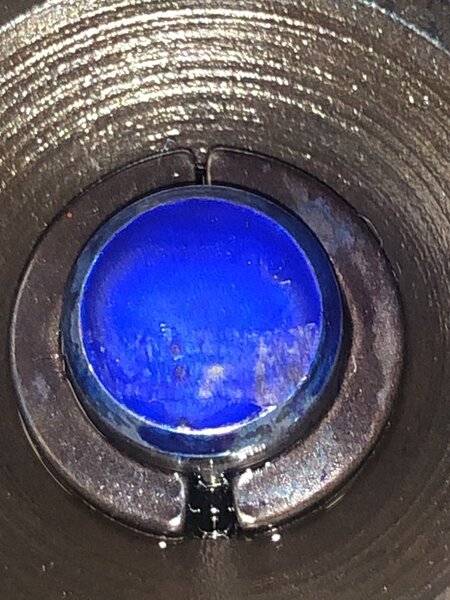

The motor in my bracket car currently has 273 adjustable iron rockers on it which ran fine last year but I wanted to upgrade. Is it reasonable to believe that I can correct the terrible geometry shown in the pics with a simple pushrod length adjustment or is there a method to change the rocker location that is fairly simple that will be needed as well? At base circle its past center to the outside and almost all the way to the edge at full lift. The dykem barely shows the mark as with it being so bad I only rolled it over a few turns.

The motor is a .030 360 with a .600" solid roller cam.

Mancini Racing Aluminum Roller Rocker Arm Kit

The motor in my bracket car currently has 273 adjustable iron rockers on it which ran fine last year but I wanted to upgrade. Is it reasonable to believe that I can correct the terrible geometry shown in the pics with a simple pushrod length adjustment or is there a method to change the rocker location that is fairly simple that will be needed as well? At base circle its past center to the outside and almost all the way to the edge at full lift. The dykem barely shows the mark as with it being so bad I only rolled it over a few turns.

The motor is a .030 360 with a .600" solid roller cam.