Hey guys and girls I just bought a 75000 mileage 318. After doing a compression test the cyl 2 failed because a cracked valve seat and cylinder 2 have bad pitting. So I sent the block to machine shop for sleeving cyl 2 because the other cylinders was in really good condition with minimal wear. I ordered a rebuild kit with new pistons, bearings, timing set and oil pump.

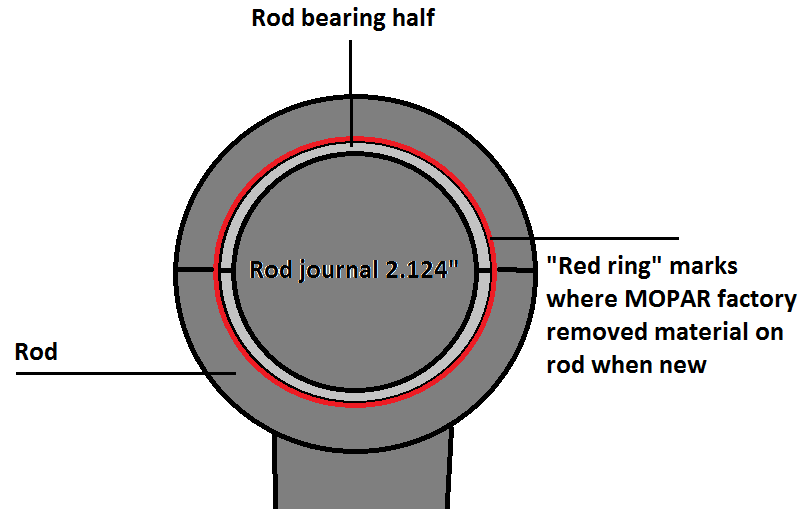

I measured the crank and rod journal with a micrometer and the numbers are: Crank journal 2.5005". Rod journal 2.124" which are STD size. The bearings mounted in the 318 where marked with AT20 which I first tought would be a .020" undersize bearing but since the journals measured STD that was what I ordered. The thing is when I test fitted the rod with the new bearing I had visible gap so I knew I ordered wrong bearings. So I measured the rods bore and it was not STD size they are .0020" "oversized". I should have measured the rods before ordering the bearings but the seller didn't have oversize bearings. My question are can I put shims that are cut out the same size as the bearings to mount under the bearing half?

Or is there any out there selling bearings that have material added on the "outside" of the bearing half to fill out where they removed material from the rod bore? AKA oversize bearings?

Thank you FABO

I measured the crank and rod journal with a micrometer and the numbers are: Crank journal 2.5005". Rod journal 2.124" which are STD size. The bearings mounted in the 318 where marked with AT20 which I first tought would be a .020" undersize bearing but since the journals measured STD that was what I ordered. The thing is when I test fitted the rod with the new bearing I had visible gap so I knew I ordered wrong bearings. So I measured the rods bore and it was not STD size they are .0020" "oversized". I should have measured the rods before ordering the bearings but the seller didn't have oversize bearings. My question are can I put shims that are cut out the same size as the bearings to mount under the bearing half?

Or is there any out there selling bearings that have material added on the "outside" of the bearing half to fill out where they removed material from the rod bore? AKA oversize bearings?

Thank you FABO