Well I think its time to start think engine build and acquiring parts and options. The suggestion box is open folks.

I'm looking for 500+ HP with a beautiful rumble and I think it should be fairly easy to achieve.

I started this engine many moons ago as you can see from the post when the block was done. I said I would if possible buy used parts and old stock from this group. So if you have usable stuff for the build chime in!

Here's where we're sitting with parts.

Block is a 440 punched 30 over with a minor deck to straighten it up. Torque plate was used.

Crank I believe is cast. 10/10 machining.

Pistons KB-237's used and in great shape mounted to LY rods. Thanks

@oldkimmer

I have 452 heads that will need a complete overhaul. Not sure its worth it. After marked heads abound.

Intake is an M1 and sitting on that will be a rebuilt Demon 750.

187 pan for the install into the Scamp.

Direct Connection A-body BB K member

Spool mounts

TTI A-body ceramic coated headers

*Gears 3.55 SG

What's needed:

Cam Thinking Hughes Whiplash Part#SMC3245BL

Timing set also Hughes Part#6427

Bearings Any suggestions? Tri metal?

Heads? With suggestions on chamber size.

Gaskets What's the pro's using?

Oil pump?

Compression ratio? (9:1 or 10.5:1)

This will be all mated to a BB 727 that I'm going to teach myself how to rebuild. Cope Racing parts look like a good option. The billet drum anyways.

What do you all think?

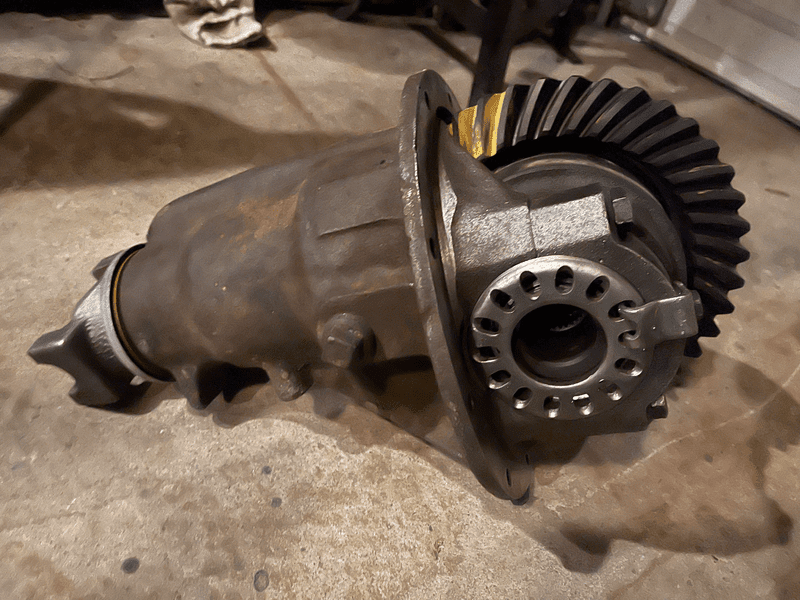

So I'm not too concerned about not using them on the centre housing as I see lots of post saying there not needed when using RTV. I'm concerned about using them on the axle retainer bolts. They look sharp though. lol Anyway if anyone sees a problem with them installed there please let me know by spring! hahaha Photo time. Drums on route.

So I'm not too concerned about not using them on the centre housing as I see lots of post saying there not needed when using RTV. I'm concerned about using them on the axle retainer bolts. They look sharp though. lol Anyway if anyone sees a problem with them installed there please let me know by spring! hahaha Photo time. Drums on route.