When I got my 470 stroker in 2016 the Comp 829s were in it for 3 tears. Prior to that they were in from 1998 to 2013. Them and the valve springs were changed in 2013. About a hundred runs per year (estimated). Some street miles. 7000 rpm every run. With the nitros Fogger system it reved to 8000 rpm. Probably close to 400 runs with the nos. Kim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid Roller Lifter Selection

- Thread starter gzig5

- Start date

-

aaronk785

Well-Known Member

Sorry wrong thread.

SS Lancer

Well-Known Member

Good company [ Atlanta ] footprint for many many years !!!Regardless of what lifters you get, or any parts for that matter, Summit pricing just doesn’t seem very good anymore. I find myself using this place as my default source. No tax and shipping usually included in most cases.

From research and user reviews I’d be eyeballing either of these for rollers with no grinding needed (that I’ve read of so far):

View attachment 1715855570

View attachment 1715855571

Krooser

Building Chinese Free Engines since 1959...

This guy gets it...Penny wise, pound foolish. I would use a SFT before I used a .750 wheel roller. It makes no sense. You have a .904 bore, so why use a wheel that is used because it it’s an .842 bore?

The manufacturers love it because it makes them big bucks.

An it’s not so much the lobes are made for what wheel, it’s the base circle diameter that makes things difficult.

What’s sad and funny at the same time is I almost never see even a decent budget chevy go together with .842 lifter bores. Why? Because they want the bigger wheel. Same reason they all run shaft mounted rockers now, when they and their ancestors who think the earth is flat spent decades and hundreds of thousands of dollars trying to prove the stud mounted rocker was the cats ***.

It’s not the 1990’s any more.

That means that 85% of the Mopars with a roller cam wouldn’t be on the street or racing. KimThis guy gets it...

PRH

Well-Known Member

I know we have had some engines on the dyno here that made excellent power with lifters that had .750” wheels.

Last edited:

Part of it..This guy gets it...

Well, I can certainly see where the bigger wheel is desirable. Probably does a bit better in longevity. It also doesn’t mean I’ll have read running a smaller wheel but there are limitations right?

Anybody have any data?

Anybody have any data?

Rat Bastid

Dunamis Metron

Well, I can certainly see where the bigger wheel is desirable. Probably does a bit better in longevity. It also doesn’t mean I’ll have read running a smaller wheel but there are limitations right?

Anybody have any data?

There you go. Any power increase is almost nothing. But the durability goes way up. Not even close. There is a reason why the GM clowns all use .904 (or bigger lifters) and it’s not to run a .750 wheel. They could do that on an .842 lifter. It’s about making them live.

Of course, if you are .650 or less lift (ball park number) and keep the engine under 6500 (Amy unwritten 65/65 rule) you can get away with a .750 wheel.

For the money saved it’s just not worth it to use the .750 wheel.

PRH

Well-Known Member

Data?

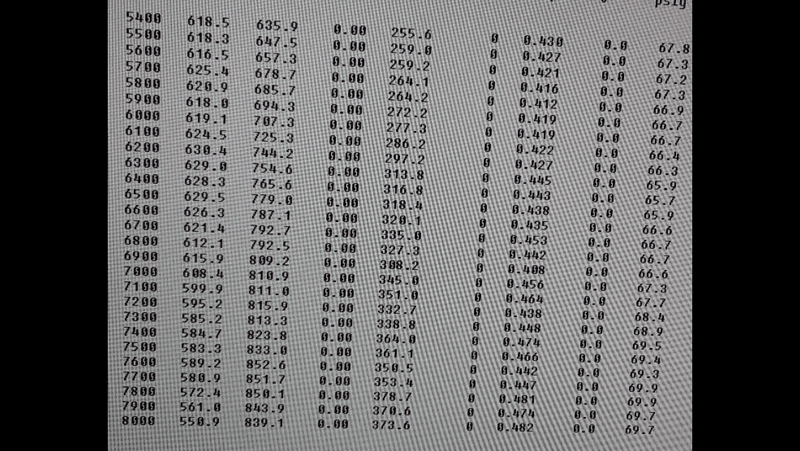

477”, stock 454 block, .842” lifters, .800” lift...... in a pulling truck, so it’s balls to the wall every time it gets run:

477”, stock 454 block, .842” lifters, .800” lift...... in a pulling truck, so it’s balls to the wall every time it gets run:

Rat Bastid

Dunamis Metron

Data?

477”, stock 454 block, .842” lifters, .800” lift...... in a pulling truck, so it’s balls to the wall every time it gets run:

View attachment 1715857292

It’s better to be lucky than good. Run what you want, but you won’t find an honest lifter manufacturer or seller who would tell anyone to use a .750 wheel if you don’t have to.

LMAO @PHR I was wondering more about a tech paper with scientific tests on longevity with test engines running for days in a clip. But THANKS! That’s very cool.

PRH

Well-Known Member

I was wondering more about a tech paper with scientific tests on longevity with test engines running for days in a clip.

Just think of the countless millions upon millions of miles that have been put on by OE built motors....... using lifters that don’t have .800 wheels(like a G3 Hemi with its .842” diameter lifters).

The main point being........ not every application requires parts selected from the bottom of the page.

Kinda what I said. Like I always do say, run what works for you.I know we have had some engines on the dyno here that made excellent power with lifters that had .750” wheels.

Matts440

Well-Known Member

I had to go with GS products for solid roller lifters for my build with Ritter block. The cross bars are on the push rod side not block side. Good quality, was trying to get the specs but their site is down for maintance.

I like things put in perspective. Let’s talk cost and availability only.

Direct oiling .750” rollers, with inboard link bars so no clearancing is needed like IQ52 mentions, will cost about $600/$770 (Howard’s/Comp) Readily available as well.

If a guy wants direct oiling .800” rollers, with inboard link bars so no clearancing needed, how much $$$ we talking? Readily available?

We have everything from serious very experienced engine builders, racers, guys who will pay for the best regardless of their application on down to maybe a guy who wants a solid roller setup in his streeter that won’t break the bank yet is reliable, and maybe doesn’t want to have to clearance his block to run them.

Direct oiling .750” rollers, with inboard link bars so no clearancing is needed like IQ52 mentions, will cost about $600/$770 (Howard’s/Comp) Readily available as well.

If a guy wants direct oiling .800” rollers, with inboard link bars so no clearancing needed, how much $$$ we talking? Readily available?

We have everything from serious very experienced engine builders, racers, guys who will pay for the best regardless of their application on down to maybe a guy who wants a solid roller setup in his streeter that won’t break the bank yet is reliable, and maybe doesn’t want to have to clearance his block to run them.

PRH

Well-Known Member

I’m fairly certain that any Comp solid roller lifter you buy nowadays that has a .904” body, has an .800” wheel.

PRH

Well-Known Member

I had to go with GS products for solid roller lifters for my build with Ritter block. The cross bars are on the push rod side not block side. Good quality, was trying to get the specs but their site is down for maintance.

That site might be down for a long time.

The owner, Glenn Steyers, passed last May.

That site might be down for a long time.

The owner, Glenn Steyers, passed last May.

He ground my custom roller cam . I had never headd of GS Products before.

Rat Bastid

Dunamis Metron

I like things put in perspective. Let’s talk cost and availability only.

Direct oiling .750” rollers, with inboard link bars so no clearancing is needed like IQ52 mentions, will cost about $600/$770 (Howard’s/Comp) Readily available as well.

If a guy wants direct oiling .800” rollers, with inboard link bars so no clearancing needed, how much $$$ we talking? Readily available?

We have everything from serious very experienced engine builders, racers, guys who will pay for the best regardless of their application on down to maybe a guy who wants a solid roller setup in his streeter that won’t break the bank yet is reliable, and maybe doesn’t want to have to clearance his block to run them.

It depends on if they are needle bearing or bushed. Either way it’s a couple of hundred bucks more for the bigger wheel. Seems cheap to me, regardless of who is putting however many miles on what.

I’ve got a customer waiting almost a year on a Dart block. I gave him the part number I wanted and he about had a stroke. So I said call Dart and tell them what you are building and see what they say.

They make OE replacement blocks and then they have race blocks. I wanted him to order a race block with a raised cam and .904 lifters. Of course, after a couple of days searching forums and talking to his buddies he was convinced I was stupid and wasting his money.

Funny thing is, Dart picked the exact block I picked. I think it’s a hundred dollar upgrade for the .904 lifter bores and I forget the what the raised cam tunnel was. They told him it makes no sense to to not do the upgrades. Same thing I told him.

Now, if Dart could just get a block out the door I could get going on it.

Matts440

Well-Known Member

Oh man I didn't hear that, forgot who I talk to over there before I bought these but great guy to talk to.That site might be down for a long time.

The owner, Glenn Steyers, passed last May.

Came across this old post:

What roller lifters?

Many of the links are bad.

What a difference 10 years makes.....

What roller lifters?

Many of the links are bad.

What a difference 10 years makes.....

Rat Bastid

Dunamis Metron

Ouch.

-