Ok in these pictures I blended the back of the bowl some and started to widen the bowl and short turn. Doing so already started to widen the short turn but I just wanted to show the start of the process. I always try to stand the head on its end for this and keep several different heights of stools so vision is right.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedmaster heads part 2. Plus intake work

- Thread starter pittsburghracer

- Start date

-

Stock short side and one after about 15 minutes work

Stock exit. Detailed and exit. Being my son is probably going to be using a 1 5/8 street type header I’m forced to stay on the small size of things. From the factory these heads have a step almost the whole way around the exit point. Just taking that out really opens the exit up some. The corners are even worse. Stock and slightly modified.

Stock pure ugliness. The gouge in the back of he bowl is bad but the cliff on the short side is terrible and could easily be fixed by anyone on this website

Last couple of pictures and due to lack of interest my last post on this. I may start another post on intake porting at a later date with flow numbers. Spark plugs holes have been modified. Other than that very little chamber work. They are going on a stock 1973 (340) so compression is low to start with.

mopowers

Well-Known Member

Man, that looks awesome! What all did you do with the spark plug hole. Smooth out the threads? How much did you unshroud the intake valve? Any unshrouding to the exhaust?

PRH

Well-Known Member

Will there be an update with the final flow numbers after you have done the valve job?

I’m not sure why you think there is a lack of interest.

Perhaps, instead of replies left behind, take a peak at the amount of views.

This current thread is an excellent tutorial that leaves little to be asked. As in a class room, the teacher is speaking and the class room is silent not due to a lack of students but it is rather an engrossed group busy taking notes and looking with eyes wide open.

The only question I have that I don’t think you can answer is about the SS radius. How much is to much and what does the recurved contour look like?

Unless you can cut the head in half or send out a template, I don’t know how you can accurately describe this to me to reproduce at home with ace results.

I am a OTJ/in the field instructor, the only interruption I get is clarification on what is said or operation of the equipment we are on if it comes up. Through the last 20 years of this, I have honed the lesson. IMO, this is what is going on here today on your thread.

Carry on please. Carry on.

Anybody who reads this hit agree if you agree with this.

Perhaps, instead of replies left behind, take a peak at the amount of views.

This current thread is an excellent tutorial that leaves little to be asked. As in a class room, the teacher is speaking and the class room is silent not due to a lack of students but it is rather an engrossed group busy taking notes and looking with eyes wide open.

The only question I have that I don’t think you can answer is about the SS radius. How much is to much and what does the recurved contour look like?

Unless you can cut the head in half or send out a template, I don’t know how you can accurately describe this to me to reproduce at home with ace results.

I am a OTJ/in the field instructor, the only interruption I get is clarification on what is said or operation of the equipment we are on if it comes up. Through the last 20 years of this, I have honed the lesson. IMO, this is what is going on here today on your thread.

Carry on please. Carry on.

Anybody who reads this hit agree if you agree with this.

Will there be an update with the final flow numbers after you have done the valve job?

May be a few days but I can post those up.

MOPAROFFICIAL

Oogliboogli

I don't know how i missed this except that im always in the smallblock section and distracted with an ailing family memeber.

Great thread.

Great thread.

Bobzilla

Well-Known Member

This was the best technical thread still active right now with the kind of hands on work I like to read about. I bought a set of the these Speedmaster bare castings just to see if I could accomplish some of the same modifications without screwing them up too expensively.

I will continue to refer back to this thread and your previous one on these heads, so I really appreciate you posting all this great information. Thank you pittsburghracer for all the time and effort you spent on this.

I will continue to refer back to this thread and your previous one on these heads, so I really appreciate you posting all this great information. Thank you pittsburghracer for all the time and effort you spent on this.

Similar here. I have the ProMaxx shocker heads (same head as seen here, just bought bare and machined on here in the U.S.) and wondered if I couldn’t just simply nudge the head along some. I PM’d PPR yesterday about the use of copper tubing and while he said he used it before, the copper was much much easier to use. So brass pipe it is for me! Thought I’d share that info. Even though he may have said that before, IDK, but here it is again.This was the best technical thread still active right now with the kind of hands on work I like to read about. I bought a set of the these Speedmaster bare castings just to see if I could accomplish some of the same modifications without screwing them up too expensively.

I will continue to refer back to this thread and your previous one on these heads, so I really appreciate you posting all this great information. Thank you pittsburghracer for all the time and effort you spent on this.

Last edited:

Similar here. I have the ProMaxx shocker heads (same head as seen here, just bought bare and machined on here in the U.S.) and wondered if I couldn’t just simply nudge the head along some. I PM’d PPR yesterday about the use of copper tubing and while he said he used it before, the copper was much much easier to use. So copper pipe it is for me! Thought I’d share that info. Even though he may have said that before, IDK, but here it is again.

brass K&S tubing I thought I said was easier.

You did and I edited the post.

(stupid me... Second time I made a simple misworded/mix up, dumb *** mistake! Dang! WTF?!? )

That’s what I ordered, KS tuning as you listed it.

(stupid me... Second time I made a simple misworded/mix up, dumb *** mistake! Dang! WTF?!? )

That’s what I ordered, KS tuning as you listed it.

yellow rose

Overnight Sensation

You did and I edited the post.

(stupid me... Second time I made a simple misworded/mix up, dumb *** mistake! Dang! WTF?!? )

That’s what I ordered, KS tuning as you listed it.

NOT ENOUGH COFFEE. Or whiskey. Or both. Those used to be my de facto excuses until I quit them both.

Now I just admit I’m old.

Ehhhhh, in simple speak...

My heads up my ***....

My heads up my ***....

jay27

Well-Known Member

No lack of interest here , This has been a great tutorial and I for one sure appreciate your time and effort and hope this thread carries to completion.Last couple of pictures and due to lack of interest my last post on this. I may start another post on intake porting at a later date with flow numbers. Spark plugs holes have been modified. Other than that very little chamber work. They are going on a stock 1973 (340) so compression is low to start with. View attachment 1715667719View attachment 1715667720View attachment 1715667721View attachment 1715667722View attachment 1715667723View attachment 1715667724View attachment 1715667725

ValiantRacing

Well-Known Member

I also notice the spark plug hole on the heads i got too, not sure what to do with it.

Bobzilla

Well-Known Member

It’s not required to anything with it. The LA Edelbrock heads and these Speedmaster heads “work” fine with those few threads exposed in regular street applications and some racing. His modification was just one more improvement in the long list of things can be done if you spend a little time on them. One less area for carbon to build up.I also notice the spark plug hole on the heads i got too, not sure what to do with it.

It’s not required to anything with it. The LA Edelbrock heads and these Speedmaster heads “work” fine with those few threads exposed in regular street applications and some racing. His modification was just one more improvement in the long list of things can be done if you spend a little time on them. One less area for carbon to build up.

Until one of our members brought that to our attention a lot of us ran their heads like that. That was fun last year with everyone checking these heads out and bringing up good questions and issues. When I say this I checked out my very best set of Edelbrock heads and they needed fixed too. I know it can’t hurt and with Matt and I running alcohol all that extra fuel should burn way better.

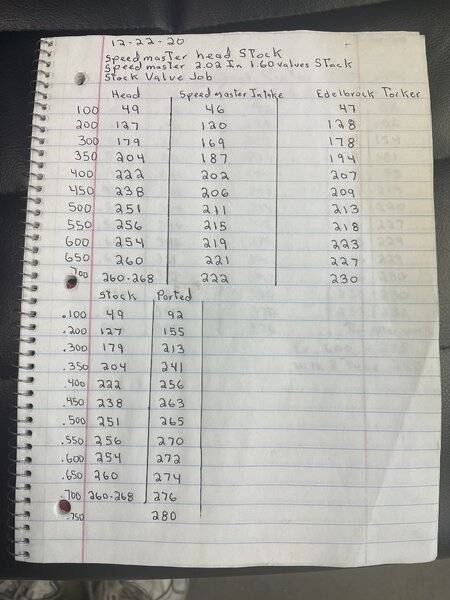

Ok some updated flow numbers and to say I’m happy would be an understatement. My whole mission was to give Ethan a good head but one that would shine with a cam under .550 lift, probably closer to .500 lift. One of the reasons I do this is to engage others and not only show what I can do but get ideas from others as I too learn something almost every time I port a head. Something I think Brian (OU812) said was in the back of my mind and here was the perfect chance to try it. He said if you don’t do chamber work the low lift numbers will be better. Hmmm perfect job to put that thinking to test. I removed some bad machine flashing left around one intake valve with a sanding roll. (Not the one I flow tested) I also relieved the spark plug holes (no affect on flow) and that was it, nothing more. I would have loved to added a 15 degree cut to the valve job but couldn’t because of the large 30 degree they cut. I added a 30 degree back cut to the speedmaster intake valves. I’m going to now retest the new speedmaster intake then port it but will start another port on that work. I have a few intakes I would like to test on this head. Ohhh I lapped in a couple of the valve jobs that came on the heads and if

all look as good as those two they will go on his car that way. Seeing these numbers give me no reason to do a valve job.

all look as good as those two they will go on his car that way. Seeing these numbers give me no reason to do a valve job.

As you can see I not only hit my 200cfm by .300 lift we hit a home run. Airspeed across the short turn was 340-380fps and handled the turn well. I will update this post with exhaust flow numbers after I get the intake testing done. Again today I checked my flowbench calibration as I always do when switching head mounts. Glad I did or I might have been scratching my head.

fishmarket

Well-Known Member

Love this stuff....still waiting for my speedmasters to arrive from the Black Friday sale. Apparently on back order.

Love this stuff....still waiting for my speedmasters to arrive from the Black Friday sale. Apparently on back order.

The Black Friday deal is a deal and a half. Enjoy your purchase

Wow is this stock intake is pathetic on ported heads. This is ugly and I don’t know being a duel plane if it’s fixable. Time to pull a rabbit out of my azz.

-