Here's a great video. It is what it is.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

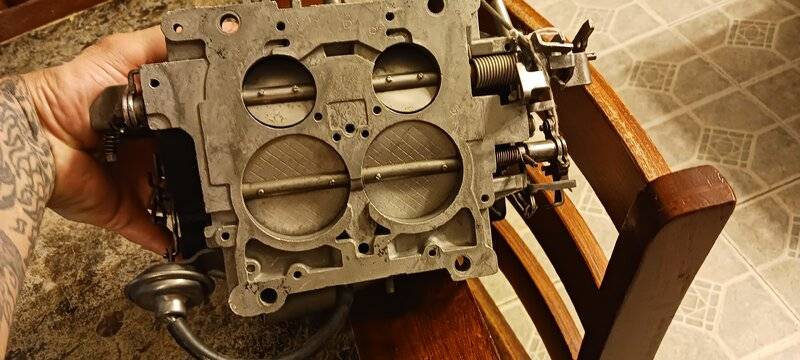

Torque plates

- Thread starter toolmanmike

- Start date

-

On our race engines (Especially Small Block Mopars)

not only do we use a Deck Plate but we home the blocks

at the water temperature that we actually stage the race cars

at. Does it make a measurable difference? I do not know but we

sure do get our feet wet a lot and go thru a lot of Socks.

not only do we use a Deck Plate but we home the blocks

at the water temperature that we actually stage the race cars

at. Does it make a measurable difference? I do not know but we

sure do get our feet wet a lot and go thru a lot of Socks.

https://www.amazon.com/GREENWATER-Waterproof-Bootfoot-Cleated-Fishing/dp/B09YHD5SBF/?tag=fabo03-20On our race engines (Especially Small Block Mopars)

not only do we use a Deck Plate but we home the blocks

at the water temperature that we actually stage the race cars

at. Does it make a measurable difference? I do not know but we

sure do get our feet wet a lot and go thru a lot of Socks.

We ever since I Epoxy Painted the shop floor it

is too slippery for those Waders! I am afraid I might

Hone Myself a new one.

is too slippery for those Waders! I am afraid I might

Hone Myself a new one.

Haven't yall won a lot? Kinda answers that question, don't it? lolOn our race engines (Especially Small Block Mopars)

not only do we use a Deck Plate but we home the blocks

at the water temperature that we actually stage the race cars

at. Does it make a measurable difference? I do not know but we

sure do get our feet wet a lot and go thru a lot of Socks.

It’s also in the wear of the piston and cylinder. How it looks at the refresh time.

This guy I have seen before and he knows what he is doing first off and second off, who ever that idiot who she is talking about is a first class *** clown that should t be allowed to have a computer, much less a 9/16th combo wrench.

Reminds me of a few *** clowns here.

This guy I have seen before and he knows what he is doing first off and second off, who ever that idiot who she is talking about is a first class *** clown that should t be allowed to have a computer, much less a 9/16th combo wrench.

Reminds me of a few *** clowns here.

Last edited:

That's still worth watching just to hear about "Fairy Dust and Unicorn Farts!"

Yep! Love listening to the guy.That's still worth watching just to hear about "Fairy Dust and Unicorn Farts!"

I edited my first post…

Love his drawl.

Love his drawl.

He said if you are building a race engine or rebuilding a certain block (like the FE Ford) you should hone with one. If honing at operating temp works for you then go for it. Like he said, If you are freshening up your wife's Yukon LS it's probably not necessary. Pay the extra and have it done if you choose.

harrisonm

Well-Known Member

Honing blocks at 'operating' temps makes SO much sense to me.On our race engines (Especially Small Block Mopars)

not only do we use a Deck Plate but we home the blocks

at the water temperature that we actually stage the race cars

at. Does it make a measurable difference? I do not know but we

sure do get our feet wet a lot and go thru a lot of Socks.

That’s it right there. IMO, while it won’t really add any meaningful power to the daily driver, the race engine will have a small benefit to it. It asked for my last engine to be bored and honed with a torque plate since it’s slated to be a race engine. It makes sense here.He said if you are building a race engine or rebuilding a certain block (like the FE Ford) you should hone with one.

Like he said, If you are freshening up your wife's Yukon LS it's probably not necessary. Pay the extra and have it done if you choose.

Exactly. I had to LOL at the keyboard warriors comment complaining at the .0004 is bad comment.

Find that measurement on your Harbor Freight digital calipers or your feeler gauges.

Sooooo stupid

We have a bunch of chickens and I have noticed =Haven't yall won a lot? Kinda answers that question, don't it? lol

Even a Blind Chicken gets a lump of Corn every now and then!

Amen

Dan the man

Well-Known Member

Would you check, set ring end gaps with the torque plates and water too?

Dan the man

Well-Known Member

I asked the above question for learning purposes only, not meaning to sound sarcastic

If you are building a sophisticated enough engine, then yes. Also if you are anal, yes!Would you check, set ring end gaps with the torque plates and water too?

How round the cylinder is makes a hell of a lot more an issueWould you check, set ring end gaps with the torque plates and water too?

with ring seal than a thou or two in the ring gap does at least

in our shop!

Dan the man

Well-Known Member

I understand that. I was on a different forum years ago and they talked heavily about using water at temperature for boring and honing blocks and they found no real difference in horsepower or ring sealing or longevity, but I don't know this as fact nor do I have any experience with it. But it seems to me that it would have a differenceHow round the cylinder is makes a hell of a lot more an issue

with ring seal than a thou or two in the ring gap does at least

in our shop!

On the ring gap question, I don’t remember where I had read it but at least one pro level builder who was using the hot water / head gasket / torque plate method used a “bench cylinder” made from a piece of stock bored and honed to “hot bore size” for setting the ring gaps.

You're the real deal GTX JOHN.....wish I was closer would love to meet you and learn some real deal super stocker proven power tips....just scored a rebuilt 1972 thermoquad 4speed carb 6138s...I'm ready to hear those secondaries suck the clouds in....

When I was buying some equipment ~20yrs ago, I discussed hot honing with them, & they said the NAPCAR guys were trying it but it wasn't getting the results they were expecting. I said that didn't make sense, & was curious why, so I stayed plugged in to it.....turned out they needed to pre-heat the honing oil, otherwise the cooler oil caused distortion, plus the type of stone was specific. Any insights of Your own You'd share? Much appreciated.How round the cylinder is makes a hell of a lot more an issue

with ring seal than a thou or two in the ring gap does at least

in our shop!

If You've ever pulled the head off of an AMC 6 including an HO 4.0L, the crosshatch is gone adjacent to the 1/2" head bolts, like a 5/8"-3/4" swath. Like He said, some get it all the time because they're prone. This is when folks don't get why a BRM 'dingleberry' hone works better needs pointing out, the engine torque plate honed itself while running & stress relieving itself, if bore taper etc. is in spec. the BRM won't undo it.He said if you are building a race engine or rebuilding a certain block (like the FE Ford) you should hone with one. If honing at operating temp works for you then go for it. Like he said, If you are freshening up your wife's Yukon LS it's probably not necessary. Pay the extra and have it done if you choose.

The part I was really listening to was when he talked about the Ford FE block getting the torque plate "no matter what" and the reason he gave was the head bolt threads were in the top right below the deck. Just like all our engines as well as most older domestic blocks. I'd like to hear his opinion on all the rest.

IntenseBlueRT

New Member

That "clown" is me... And his entire video is a misconstruing of what was said. Massively misleading.It’s also in the wear of the piston and cylinder. How it looks at the refresh time.

This guy I have seen before and he knows what he is doing first off and second off, who ever that idiot who she is talking about is a first class *** clown that should t be allowed to have a computer, much less a 9/16th combo wrench.

Reminds me of a few *** clowns here.

-