Jim910

Well-Known Member

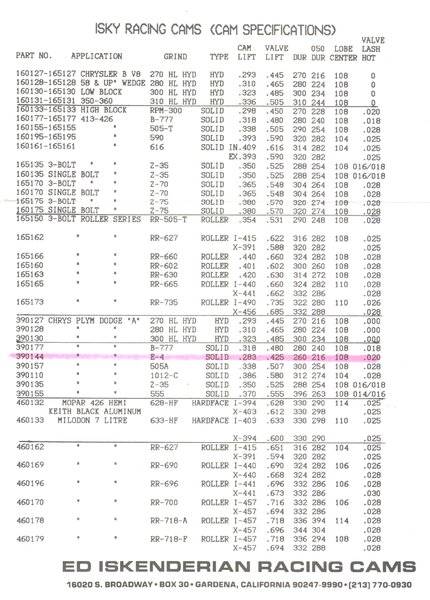

Hello, I am going to adjust the valve lash on my 1967 Barracuda 'S', 273ci, that I just got. The previous owner installed an Insky cam when he rebuilt the engine. The Cam Card shows .020 gap for both the intake and exhaust valves. I just want to make sure that I'm reading this right being that on a stock cam the intake and exhaust lash are different. Also, could anyone please tell me what I can expect performance wise from a 273 bored 30 over with Egge pistons and this cam and a Edelbrock carb. Many thanks for any help.