ill try to keep this short

first off i have a 72 duster with a 360 v8 in it with electric ignition.

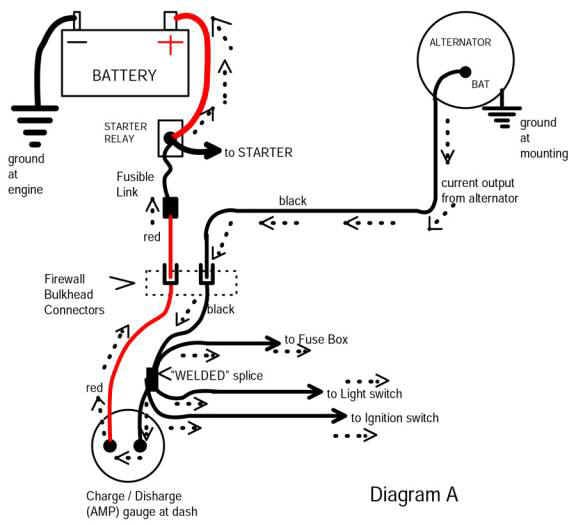

i have removed the amp meter since it almost caught my car on fire and i added the electric ignition my self and when i first got the car the voltage regulator went out and i replaced that also.

now for the problem when im driving my car the voltage meter reads between 13.8 to 14.9 and my turn signals work fine. then when i go to slow down and stop, the voltage slowly goes down and the turn signal starts to slow down, then when i get stopped and the car idles the voltage rests at around 10.8v and the turn signals freezes. when i feather the gas the voltage goes back up.

if it matters my idle is around 600 rpm

im assuming it has something to do with the alternator but i dont want to just start replacing parts and hope it fixes it.

any advise would be great.

Thanks.

first off i have a 72 duster with a 360 v8 in it with electric ignition.

i have removed the amp meter since it almost caught my car on fire and i added the electric ignition my self and when i first got the car the voltage regulator went out and i replaced that also.

now for the problem when im driving my car the voltage meter reads between 13.8 to 14.9 and my turn signals work fine. then when i go to slow down and stop, the voltage slowly goes down and the turn signal starts to slow down, then when i get stopped and the car idles the voltage rests at around 10.8v and the turn signals freezes. when i feather the gas the voltage goes back up.

if it matters my idle is around 600 rpm

im assuming it has something to do with the alternator but i dont want to just start replacing parts and hope it fixes it.

any advise would be great.

Thanks.