Found my old W2 heads I bought from friend in 2002. '810 castings from late 1970's (I believe) ported in NN VA before I bought them. Researching W2 historical stuff showed many different versions. A lot of confusion! Here's my heads which "appear" to have never been bolted on. Ported with 2.08 intakes, 1.60 exhaust. Maybe thread can contribute to knowledge here of W2 head versions, or not. : )

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

W2 Heads

- Thread starter DC 340

- Start date

-

Chamber side?

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,248

- Reaction score

- 12,264

Early castings, freeze plugs in end are a give away. You wont like this, but in my opinion they are the LEAST desirable of all the W2 versions. They have the LA exhaust bolt pattern, no decent bolt on headers due to port mismatch. Short turn has a very weird oval shape they quickly went away from, and these are crack prone.

I was wanting to know closed or open chamber. The 810 came both ways. at 65cc, they could be either.Hi RRR. My data from many moons ago measured 65cc. I do not know if they have been milled. They are what they are though. : )

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,248

- Reaction score

- 12,264

I think the early versions like this were all open chamberI was wanting to know closed or open chamber. The 810 came both ways. at 65cc, they could be either.

For sho and fo certain! Thanks! They look ok. I'd use um.

TTI has header with the narrower standard head bolt spacing.

This head should make a car hustle pretty well.

This head should make a car hustle pretty well.

19DART66

Well-Known Member

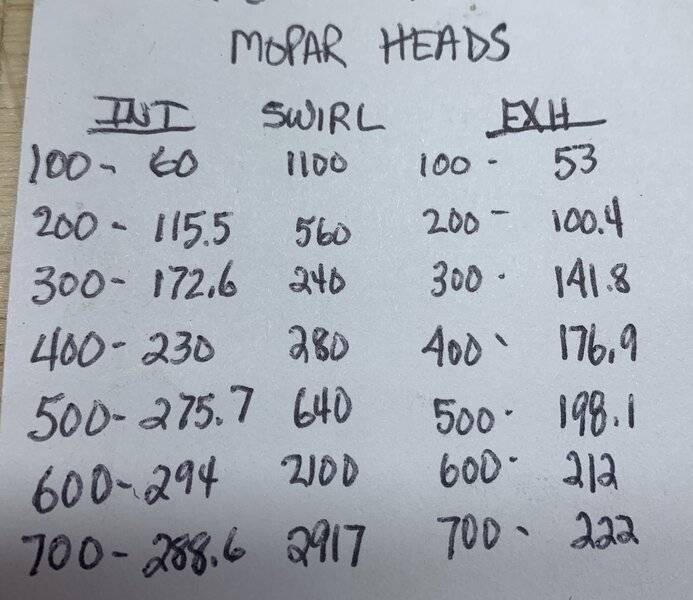

I ran a set of 810 W2 with 2.08 intake valves just like those, ported with the DC porting templates back in the late 80's and 90's. If I remember right they flowed around 290 cfm intake and 200 cfm exhaust.

They had the small bolt pattern on the exhaust ports. But the Headman headers I ran with them came with a seperate flange that bolted to the small bolt pattern, and the headers bolted to the flange with 4 bolts on each outboard port and either 5 or 6 bolts (can't remember) for the 2 inboard ports.

The headers were A body 1 7/8 tubes with perfectly round ports and they were on a 69 Dart.

They had the small bolt pattern on the exhaust ports. But the Headman headers I ran with them came with a seperate flange that bolted to the small bolt pattern, and the headers bolted to the flange with 4 bolts on each outboard port and either 5 or 6 bolts (can't remember) for the 2 inboard ports.

The headers were A body 1 7/8 tubes with perfectly round ports and they were on a 69 Dart.

Thanks '66. I have those flanges or what I would call adapter plates. I bought (a long time ago) Hedman Hussler W2 headers that bolt to that plate. I think my headers are 2" tubes. These plates need to be port matched before I use them.

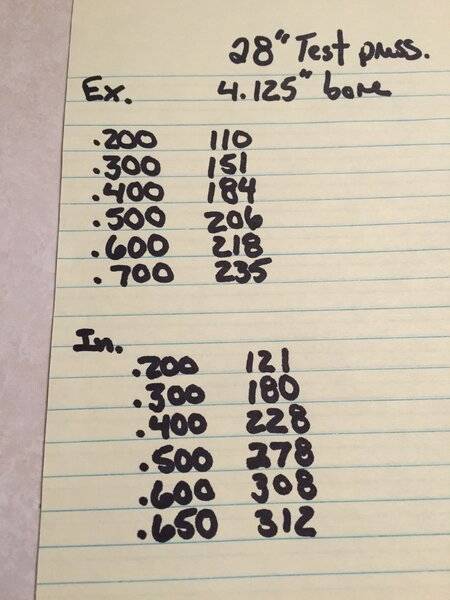

The two different flow numbers can be related to the fixture plate under the head. Other factors as well. I also have two different flow sheets for my W5 heads. The smaller bore fixture plate under the head produced lower numbers but more relatable to what I would have used them on.

1st bore plate was a 4.03. Second plate was a gigantic 4.125.

Look familiar-ish next to your numbers?

1st bore plate was a 4.03. Second plate was a gigantic 4.125.

Look familiar-ish next to your numbers?

PRH

Well-Known Member

I found some flow numbers on my heads from 20 years ago. Two different occasions by different flow benches. I'm not sure sure why the difference, maybe different ports or something.

Another good example of why it’s not a good idea to try and compare numbers from different benches as “apples to apples”.

Best to have before/after numbers from the same bench, although I realize that’s not always possible.

Hi rumblefish360. Thanks for those numbers, yea they look familiar-ish. : ) I have no idea what differences existed on the 2 benches. The "Evans" numbers were given to me when I bought the heads. The "Rob" numbers were done by a friend for me as he had access to a flow bench in a machine shop. I wasn't able to witness either setup. But I am glad to have some data since these were ported.

Now this part I am not sure of its purpose. It's a spacer/bolt package P4007712. I know one is used on each head where the head bolt boss is low over the intake runners. I always read you need these for ported W2s. I am guessing they help distribute the head bolt clamp force over the ported intake runners since that area is thinned from porting. Anyone know if this is correct?

Do yourself a favor and cut those adapters in three pieces

Rat Bastid

Dunamis Metron

Now this part I am not sure of its purpose. It's a spacer/bolt package P4007712. I know one is used on each head where the head bolt boss is low over the intake runners. I always read you need these for ported W2s. I am guessing they help distribute the head bolt clamp force over the ported intake runners since that area is thinned from porting. Anyone know if this is correct?

View attachment 1716016633

Those bolts and spacers go into the short head bolt hole on each head. I’m talking about the one short bolt in the upper row on each side.

When you correctly (fully) port any early W2 or Pcar head, you will break through into that low bolt boss.

That spacer gets glued into the bolt boss where you break through to seal the leak.

I‘m jealous of your rockers. Those Norris Rockers are the cats arse for sure.

Edit: Please take PBR’s advice and cut those adapter flanges into three pieces. They suck when they are one piece like that, and they will leak (most likely). And you’ll probably have to use a plug with a 5/8 hex like a C series Champion because even with the adapter cut and trimmed it’s hard to get a 13/16 hex plug in there.

Plus those 13/16 hex plugs are just plain clunky.

Thanks PBR and Rat Bastid! I did look at the head bolt boss on each head and did not see any break through but I do not know how thin that area is. I will probably put the spacer there anyways since the ARP head bolt kit I have has the long head bolt for that area. On the exhaust plate, yea I noticed getting a standard spark plug in and out with the plate attached is damn near impossible.

No problem. I’m just glad to show what two bench operators come up with and part of the reason. The bigger the bore, the more the head or engine can intake from the head. I was shown & taught a few things from the second head flow operator who I know and trust for a long time now. His dad and him have been build winning engines for decades and he was taught how to port heads by Joe Modello.Hi rumblefish360. Thanks for those numbers, yea they look familiar-ish. : ) I have no idea what differences existed on the 2 benches. The "Evans" numbers were given to me when I bought the heads. The "Rob" numbers were done by a friend for me as he had access to a flow bench in a machine shop. I wasn't able to witness either setup. But I am glad to have some data since these were ported.

I showed him the prior results and he was pretty sure they would be very close and the other persons numbers were accurate but may very differ if he also got the 4.125 plate on the bench. Having the same plate is not a guarantee of the same results.

The best part of it all was when I walked in he was excited to see me and said that these were really nice and I’ll have no problem making power for my goals. I didn’t say who ported the heads by he made the compliment of it being a really nice job with a smile on his face.

So I’m happy with them. I am disappointed in the head giving up the ghost on a port, which stopped any further porting efforts on the pair. I did want more cfm for the planned large stroker, but it wasn’t to be. It’s enough though.

-

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 13

- Views

- 3K

- Locked

[FOR SALE]

2 sets W2 heads, strip dominator intake

- Replies

- 3

- Views

- 2K

- Locked

- Replies

- 20

- Views

- 3K