You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding

- Thread starter CRUZE 418

- Start date

-

Some suggest unplugging the ECM as well.

MoparMike1974

Well-Known Member

You should always put the ground close to the work. Not just in this instance. On these old cars just disconnecting the battery is really all you need to do. If you have a newer MSD that plugs in or other brand with a plug, it sure wont hurt to take the extra precaution. If its got fuel injection I would disconnect the module.

Cover your nice paint around the area before welding to keep spatter off it. They actually make a masking paper specifically for this.

Cover your nice paint around the area before welding to keep spatter off it. They actually make a masking paper specifically for this.

pishta

I know I'm right....

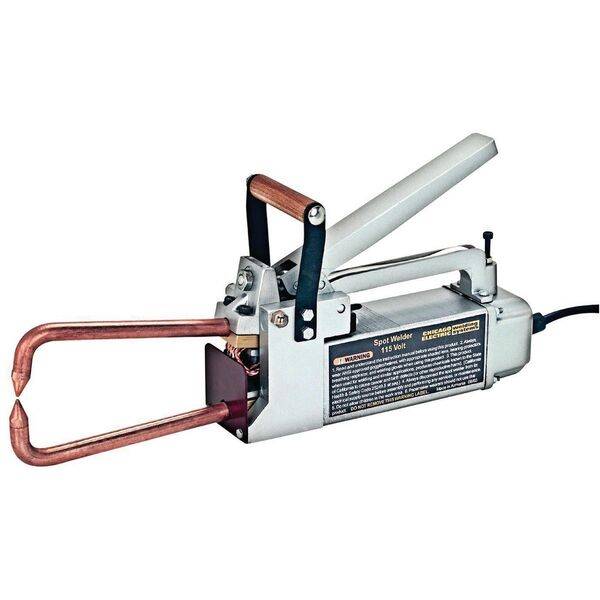

get as good a fitment as possible before plug welding it. Go to town with this thing!

Okay . All advice noted. Just put all of the associated parts on around the lower radiator support, the new support will not be located exactly where the old one was.

Seems like my shop accident favored the driver's side for some reason, will reposition with a Porta power. Radiator fits, but the opening is out of square on the driver's side, about 3/16". From the old paint lines ,

the lower radiator support wasn't in there to the tabs (frame stops) anyway. Trying to watch for bottom of radiator tank clearance. If any of you are by profession body men, probably think that worrying about 3/16" is funny. I am just trying to get it as close as I can. Actually, everything fits the way it is.

Thanks again for the tips!

Seems like my shop accident favored the driver's side for some reason, will reposition with a Porta power. Radiator fits, but the opening is out of square on the driver's side, about 3/16". From the old paint lines ,

the lower radiator support wasn't in there to the tabs (frame stops) anyway. Trying to watch for bottom of radiator tank clearance. If any of you are by profession body men, probably think that worrying about 3/16" is funny. I am just trying to get it as close as I can. Actually, everything fits the way it is.

Thanks again for the tips!

When I assembled mine, I put the rad support to the frame stops and welded it in. Then the rad didn't fit. Why the hell are the frame stops even there? Re-do!

doug 371

Well-Known Member

same number and placement of factory welds

Dartnut

Don't hate me because i'm beautiful

Practice on some scrap metal the same thickness as you are going to weld to get the heat settings right unless you already know for sure what you are doing.

And, fit up is critical for strength and ease of welding.

Also, cleanliness is a must!

And, fit up is critical for strength and ease of welding.

Also, cleanliness is a must!

My Mopar buddies son is a certified welder, I will probably have him do the welding. It's been 40 years since my last mig weld. As far as positioning of the welds, they will probably be different, but proper spacing of 3/8" plugs vs 1/4". That was advice from another body guy that loaned me a pneumatic punch. Yes, clean and proper preparation. The factory spot welds were not exactly placed as most know.

Blaine Davis

Well-Known Member

Make sure to get a good weld through primer also, I personally like Spray Max brand and i use it between every plug weld i do

-