72Duster440

Well-Known Member

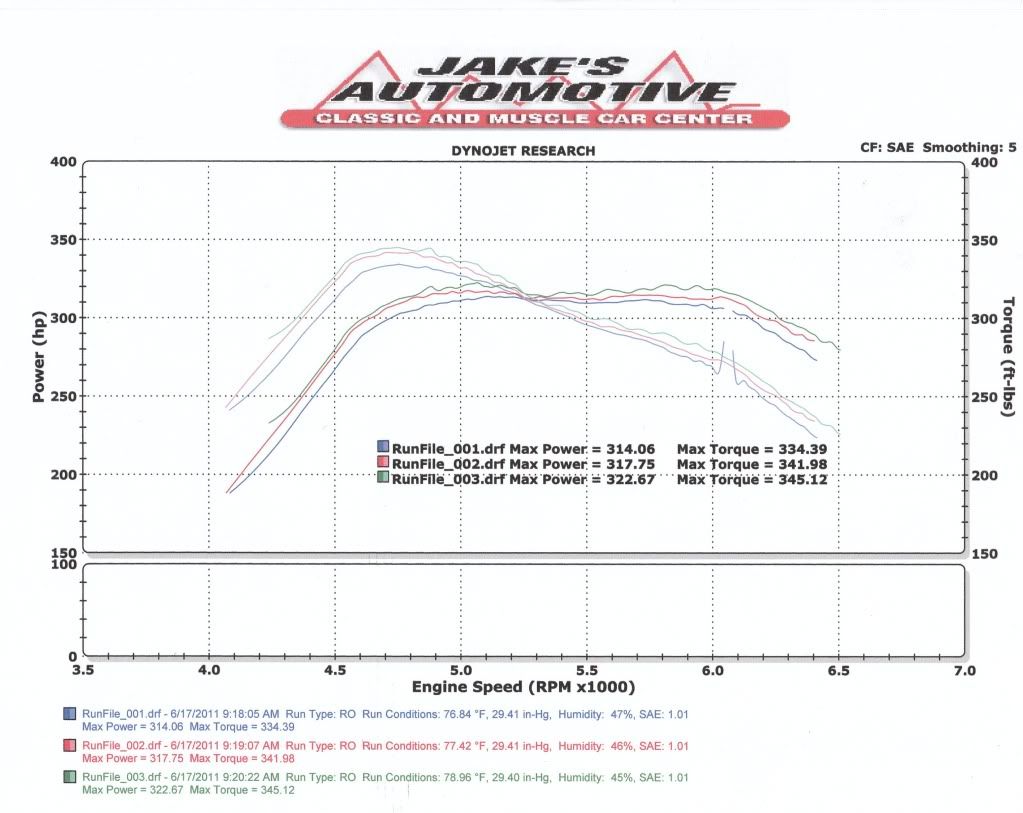

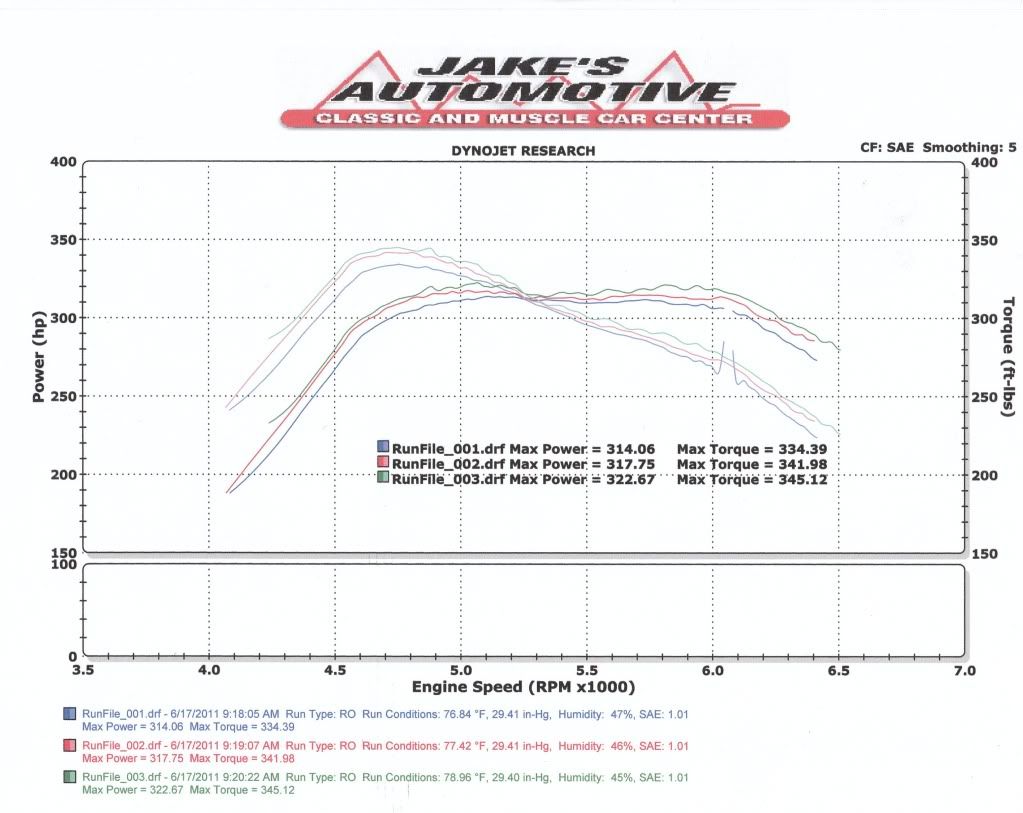

And pulled less power than I was expecting. It was sure blowing the carbon out of the motor though on the first couple pulls.

Here's the specs that I know on the motor, I haven't done anything to it since I got it.

1967 HP 440 BLOCK, RODS AND CRANK

FORGED TRW FLAT TOP PISTONS

572 CRANE CAM

915 CLOSED CHAMBER HEADS, PORTED, POLISHED AND FLOWED

2.14 INTAKE AND 1.81 EXHAUST VALVES WITH DOUBLE SPRINGS

MOPAR PERFORMANCE SINGLE PLANE INTAKE

HOLLEY 780 VACUUM SECONDARY CARB

2 PRIMARY LONG TUBE HEADERS WITH HOOKER MUFFLERS

MSD 6A IGNITION BOX

One thing we did notice on the last pull, above ~5500rpm the fuel pressure dropped to 1-2psi, but even at idle I can't get it above 5psi regardless of where the regulator is set. I also noticed that the fuel filter after the pump barely has any fuel in it.

Would this be a puel pump on the way out?

Here's the specs that I know on the motor, I haven't done anything to it since I got it.

1967 HP 440 BLOCK, RODS AND CRANK

FORGED TRW FLAT TOP PISTONS

572 CRANE CAM

915 CLOSED CHAMBER HEADS, PORTED, POLISHED AND FLOWED

2.14 INTAKE AND 1.81 EXHAUST VALVES WITH DOUBLE SPRINGS

MOPAR PERFORMANCE SINGLE PLANE INTAKE

HOLLEY 780 VACUUM SECONDARY CARB

2 PRIMARY LONG TUBE HEADERS WITH HOOKER MUFFLERS

MSD 6A IGNITION BOX

One thing we did notice on the last pull, above ~5500rpm the fuel pressure dropped to 1-2psi, but even at idle I can't get it above 5psi regardless of where the regulator is set. I also noticed that the fuel filter after the pump barely has any fuel in it.

Would this be a puel pump on the way out?