Please tell me something I don't know.

also the intake valve chases the piston and the piston chases the exhaust.

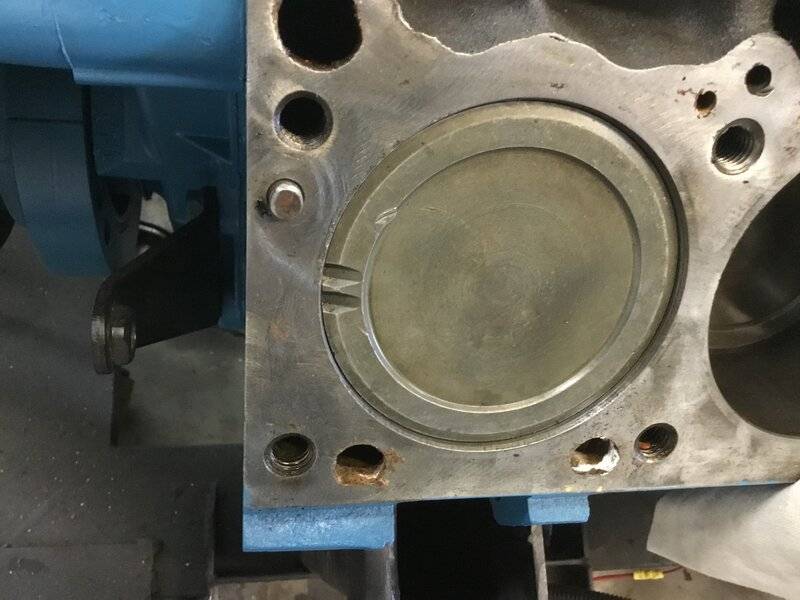

The piston is damn near tdc when the exhaust closes

Right. And if (this is a big IF because cam companies don’t normally give this spec) you know your valve opening at TDC for the intake centerline you use you can figure out it doesn’t take being off very much to crash a valve.

Comp is the only one I know that gives that spec and it’s usually for a 106 and 110 ICL.

Long, slow cams have far less valve opening at TDC than do lobes that are much faster with the same at .050 timing.

And since the intake does follow the piston down the hole, you only need piston to head clearance for intake piston to valve clearance.

That means if you run .040 piston to head clearance and the pistons don’t hit you can run .040 piston to valve clearance on the intake valve. I wouldn’t do that with a timing chain.

Reher-Morrison says the exact same thing except they at .010 extra clearance just for a little more margin.

For the exhaust side, they use whatever your intake valve clearance is times 1.6-2.0 and send it.

That means if you have .050 clearance on the intake valve you need .080-.100 on the exhaust valve.

Most guys run way more than that and it just pisses away compression.