I am building a 512 from a 440 block. I have read the chapters from Andy's and Chuck Senatore's books and I am still confused. In chuck's book he says that the stock pump is good for 8,000 rpm and then also says that the 3/8 pickup is too small. Andy indicates that redrilling the 3/8 to 1/2 has a compound drilling angle and if it is messed up, you will need an external pickup. I am not trying to re-invent the wheel. I just want something that works. My question is ...Would a 7 quart deep pan with a 3/8 pickup and a high volume oil pump be able to meet the needs for this setup? It will have a supersniper efi and later have a 150 boost of nitrous. This will be a street/strip 1973 scamp. What systems work for large stroker motors? I like the simplicity of just installing a high volume pump to replace stock but I also want to have sufficient volume and pressure . Any comments on windage trays and acceleration and deceleration baffles welcome.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What oil pump to use?

- Thread starter Kent mosby

- Start date

-

Mattax

Just the facts, ma'am

It would be nice if everyone's answer was the same on this one.

I can offer some guidance, which hope will be of some help.

Fundamentally, additional volume is needed if the bearing clearances are large or something like that.

A high volume pump is definately a part of a fully thought out system. It has taller rotors, and will suck up more oil per minute than the standard pump.

Thats not always good. That extra volume could end up getting blown out the relief valve, or sitting under the valve covers etc slowly making its way back down. In these cases the sump level is low, and the oil aerated.

Here's the way I'd try to approach the system.

Use rpm and the bearing clearances to get a sense of whether the Volume per minute will be beyond a stock pumps capacity.

A deep pan (assuming ground clearance is not an issue) will never hurt. OK a little slower on warming up. No biggie.

Decide about going to a larger pickup after deciding about whether its going to need more volume per minute.

Pick a spring based on rpm. A high spinning engine will likely do better with a higher spring pressure.

Select an oil grade for the bearing clearances and temperatures.

I can offer some guidance, which hope will be of some help.

Fundamentally, additional volume is needed if the bearing clearances are large or something like that.

A high volume pump is definately a part of a fully thought out system. It has taller rotors, and will suck up more oil per minute than the standard pump.

Thats not always good. That extra volume could end up getting blown out the relief valve, or sitting under the valve covers etc slowly making its way back down. In these cases the sump level is low, and the oil aerated.

Here's the way I'd try to approach the system.

Use rpm and the bearing clearances to get a sense of whether the Volume per minute will be beyond a stock pumps capacity.

A deep pan (assuming ground clearance is not an issue) will never hurt. OK a little slower on warming up. No biggie.

Decide about going to a larger pickup after deciding about whether its going to need more volume per minute.

Pick a spring based on rpm. A high spinning engine will likely do better with a higher spring pressure.

Select an oil grade for the bearing clearances and temperatures.

This new build should be closely toleranced. I will be doing a break in on a Run Stand and will monitor the oil pressure with the standard spring and high volume oil pump and check the pressures at different rpms. At that point I can be sure about the pressures. If that is not a good approach, please advise. Thanks

Mattax

Just the facts, ma'am

IMO, high volume pump isn't needed with tighter bearing clearances.

High pressure relief spring might be good if running over 7000 rpm.

I'm just looking at this from my general experience and fluid flow.

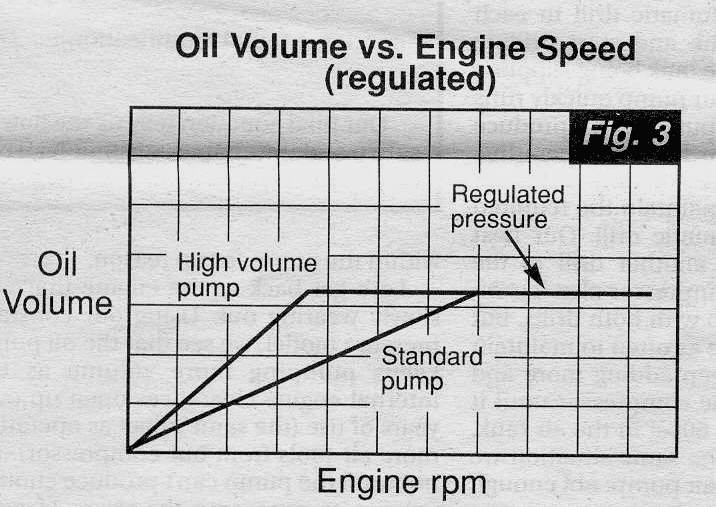

Here's a general graph of volumetric flow (gal/min) vs. rpm.

This flow into the engine (after the relief valve) with hot oil.

Is there any specific reason this engine will need more volume flowing earlier in the rpm range?

If not, I don't see why a high volume pump is needed. It will increase the load on the tip of the shaft etc. IIRC there is a hardened intermediate gear for the BB. I have one for the LA engine even though I am using a standard volume pump.

There was hot rod magazine article where they showed pump output (both flow and pressure).

All I can find now is Jeff Smiths description. The link goes to the original article and photos; but the charts are not showing, at least for me.

Jeff Smith Technical Questions and Answers - Car Craft Magazine

Also a good threads at moparts.

Of course use breakin oil for break in.

Oil Viscosity vs Bearing Clearance | Unlawfl's Race & Engine Tech | Moparts Forums

and Andy suggests starting with a standard volume pump here:

When to use / not use a high-volume oil pump? | Unlawfl's Race & Engine Tech | Moparts Forums

High pressure relief spring might be good if running over 7000 rpm.

I'm just looking at this from my general experience and fluid flow.

Here's a general graph of volumetric flow (gal/min) vs. rpm.

This flow into the engine (after the relief valve) with hot oil.

Is there any specific reason this engine will need more volume flowing earlier in the rpm range?

If not, I don't see why a high volume pump is needed. It will increase the load on the tip of the shaft etc. IIRC there is a hardened intermediate gear for the BB. I have one for the LA engine even though I am using a standard volume pump.

There was hot rod magazine article where they showed pump output (both flow and pressure).

All I can find now is Jeff Smiths description. The link goes to the original article and photos; but the charts are not showing, at least for me.

Jeff Smith Technical Questions and Answers - Car Craft Magazine

Also a good threads at moparts.

Of course use breakin oil for break in.

Oil Viscosity vs Bearing Clearance | Unlawfl's Race & Engine Tech | Moparts Forums

and Andy suggests starting with a standard volume pump here:

When to use / not use a high-volume oil pump? | Unlawfl's Race & Engine Tech | Moparts Forums

That is a great amount of info. I appreciate the info. I will read all the info tonight.

A standard oil pump with 1/2 half pickup tube will outflow a high volume pump with a 3/8 pickup tube.

We use to drill the 383 & 440s to use the hemi pickups.

We use to drill the 383 & 440s to use the hemi pickups.

moper

Well-Known Member

The determination of the volume is a function of the clearances and rpm expected. What are yours?

As to clearances, this is a new build and we will be using 1/2 groove main bearings. The RPM will be 6800 or so, hopefully. Not sure. I will run it on the run stand and see about the oil pressures throughout the rpm range and if needed, upgrade before final install.

leblanc

member 2883

I am building a 512 from a 440 block. I have read the chapters from Andy's and Chuck Senatore's books and I am still confused. In chuck's book he says that the stock pump is good for 8,000 rpm and then also says that the 3/8 pickup is too small. Andy indicates that redrilling the 3/8 to 1/2 has a compound drilling angle and if it is messed up, you will need an external pickup. I am not trying to re-invent the wheel. I just want something that works. My question is ...Would a 7 quart deep pan with a 3/8 pickup and a high volume oil pump be able to meet the needs for this setup? It will have a supersniper efi and later have a 150 boost of nitrous. This will be a street/strip 1973 scamp. What systems work for large stroker motors? I like the simplicity of just installing a high volume pump to replace stock but I also want to have sufficient volume and pressure . Any comments on windage trays and acceleration and deceleration baffles welcome.

Ask that question to some big block racer would be your best bet.

383Scampman

Well-Known Member

I took my approach to bb engine oiling from Herb McCandless . #1, the hole that feeds the main bearing comes from the oil gallery . It is a 3/16ths" stepped hole to restrict flow to the mains . Herb suggested to drill it all the way (long drill) to 3/16ths". #2, fully grooved main bearings "P" series .#3 Milodon or Moroso 7quart pan and pickup. #4, start with a standard volume Melling pump . #5, monitor oil pressure during break in and if oil pressure does not go up after break-in and run in , go to a high volume pump . Because of grooved main bearings expect lower oil pressure than you would think . #6 experiment with different weight oils until you're happy with the pressure at the finish line . In my case oil pressure was low with 10w-30 and standard pressure . After about 3hours of running time and an oil change oil pressure went up to 25 lbs at idle (1000rpm) to 55lbs at 4800 lbs. Herb is a genius with bb's and Hemi's.

famous bob

mopar misfit

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^A standard oil pump with 1/2 half pickup tube will outflow a high volume pump with a 3/8 pickup tube.

We use to drill the 383 & 440s to use the hemi pickups.

THIS

I WOULD NOT USE A HI VOLUME PUMP W/ A 3/8" PICK UP , ESPECIALLY IN A STOCK OIL PAN. HEMI PICK UP YES.

moper

Well-Known Member

As to clearances, this is a new build and we will be using 1/2 groove main bearings. The RPM will be 6800 or so, hopefully. Not sure. I will run it on the run stand and see about the oil pressures throughout the rpm range and if needed, upgrade before final install.

Your plan and answers are raising a few red flags with me.

Not sure the 1/2 grooves are the way to go. Not a long stroke, not living at 6800rpm.

You are not answering the clearances question and setting the pressure "after it's dyno'd" is just totally *** backward. If you are using a stroker kit the clearances need to be measured. We're talking about thousandths of an inch here. .002" clearance is fine with one setup. .003 or over should have more. So it's not a "we'll see". If it's a stroker kit, get the parts, have the block machined (assuming the main bores are also being done) and have everything measured with the right tools. Not plastigage. Only once those are known via empirical means can you really determine what system will be adequate. Also FYI - most kits with lower and medium price points will have clearances that are all over the board.

IMO, a stock pump and pickup will not be enough for the rpm you're suggesting. You need a little wider clearances for it, some internal passage modifications, and a full grooved set of mains for that rpm. I would plan to open the factory pickup passages, including rounding off the sharp bend in the passage above the pickup boss, and enlarging the main feeds from the passenger side lifter galley. I'd spec an HV pump because it will need the volume. BTW - no HV pump I know of comes with a std relief spring. They all have the HP spring in them... A better pan would be some insurance - even if it's just the Hemi style factory unit with a windage tray.

I'm not sure what you have for a head choice. To make power at those rpm levels you've got to be putting some real heads and cam on it too. And those heads and/or cam may have different oiling needs too.

@moper You bring up some important food for thought. The stroker kit I have is from 440 source. They package everything together with what I thought was good components with respect to bearings. The machine shop did the main bore and measured (miked) the components. I will redo the measurements myself before proceeding. I found a really thorough article that helps with bearing selection and concepts of oiling. I skimmed it but I will read thoroughly before measuring this weekend. Thanks for the help @moper. I want to assemble this once correctly.

How to Select and Install High-Performance Engine Bearings - Hot Rod Network

How to Select and Install High-Performance Engine Bearings - Hot Rod Network

So, what’s ur update? Got the clearances? No progress? Kim

famous bob

mopar misfit

It would be nice if everyone's answer was the same on this one.

I can offer some guidance, which hope will be of some help.

Fundamentally, additional volume is needed if the bearing clearances are large or something like that.

A high volume pump is definately a part of a fully thought out system. It has taller rotors, and will suck up more oil per minute than the standard pump.

Thats not always good. That extra volume could end up getting blown out the relief valve, or sitting under the valve covers etc slowly making its way back down. In these cases the sump level is low, and the oil aerated.

Here's the way I'd try to approach the system.

Use rpm and the bearing clearances to get a sense of whether the Volume per minute will be beyond a stock pumps capacity.

A deep pan (assuming ground clearance is not an issue) will never hurt. OK a little slower on warming up. No biggie.

Decide about going to a larger pickup after deciding about whether its going to need more volume per minute.

Pick a spring based on rpm. A high spinning engine will likely do better with a higher spring pressure.

Select an oil grade for the bearing clearances and temperatures.

This^^^^^^^^^^^^^^^^ ^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

plus , u might need more oil for other losses thru out the system. I would put a long 3/8" pipe nipple in the block , to get a good idea of the correct angle to drill it out for a 1/2" pick up, if running a hi volume pump , w/ a deep /larger oil pan.

I extended a 1/2" pick up on a hemi superstocker for a deep tierod/tube type oil pan, I extended it 6-7" then heated and bent the pipe to get the appropriate angle to fit the pan, so it would be level and 3/8" off the floor of the pan, It ran that way for 14 years of hard racing !

Altho the pan was a bit of ***** to get off under the car, with pulling the tierod and trying to screw it off.

No Progress at this time. Life got in the way for a while.

moper

Well-Known Member

@moper You bring up some important food for thought. The stroker kit I have is from 440 source. They package everything together with what I thought was good components with respect to bearings. The machine shop did the main bore and measured (miked) the components. I will redo the measurements myself before proceeding. I found a really thorough article that helps with bearing selection and concepts of oiling. I skimmed it but I will read thoroughly before measuring this weekend. Thanks for the help @moper. I want to assemble this once correctly.

How to Select and Install High-Performance Engine Bearings - Hot Rod Network

The issue, if you're using Source parts, is that the clearances will more than likely be all over the place. And THAT, is where things get messed up. Source parts are "good". They are not "great". Things like taper and journal size will vary journal to journal, and it's hard to plan and say "it will be fine" when one clearance is factory min and the next is a hair over factory high. Welcome to that price point...

-

Similar threads

- Replies

- 16

- Views

- 767

- Locked

- Replies

- 0

- Views

- 66