I purchased an inline electric fuel pump for the sole purpose of priming the carb when the car has been sitting for a week or two and all of the fuel has evaporated. I was thinking I just needed a momentary switch with two connectors to complete the circuit. As I usually do, I have been overthinking this and figured I should run an on-off-on switch which is momentary on one side and fixed on the other side. My thinking is that I would use the momentary side for priming, but in case the mechanical fuel pump ever fails, I could just switch the pump on. I don't have a great grasp of electrical wiring, so here is my question. The on-off-on switches I am seeing have three connectors instead of two. How would I wire it? I suppose the simpler alternative would be a regular two connector on-off toggle switch, and just turn it on long enough to prime the carb?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wiring priming fuel pump

- Thread starter qkcuda

- Start date

-

Professor Fate

Push the button, Max...

Whichever switch you go with, wire it to a relay and not directly to the pump.

Thanks, I ran a relay to the Carter pump on the old race car. I also ran a momentary switch and an oil pressure shut off since it ran all the time. This one is a low pressure pump that doesn't draw much power, so I was thinking of just running it direct to the switch?

Look at the amp draw of the pump and match the switch to the pump draw. (overkill by a few amps is recommended) If you run a relay, you can energise it with a light duty switch. The power should be fused for safety and only use a momentary switch.

This is a Carter P60430 pump. The only specs I have been able to find reference "low amp draw" The Carter race pump I used to have says it draws 5-7 amps, so I assume it would be something less than that. I will use an inline fuse, and probably just stick to a momentary switch. The ones I have looked at seem to be rated for at least 10-15 amps.

I need to do this to my car also, thinking about having a push button switch mounted in the cigarette lighter hole. Would the electric pump be before the mechanical fuel pump or after?

That should work fine.This is a Carter P60430 pump. The only specs I have been able to find reference "low amp draw" The Carter race pump I used to have says it draws 5-7 amps, so I assume it would be something less than that. I will use an inline fuse, and probably just stick to a momentary switch. The ones I have looked at seem to be rated for at least 10-15 amps.

Those pumps are made to push and not pull so it needs to go back by the tank.I need to do this to my car also, thinking about having a push button switch mounted in the cigarette lighter hole. Would the electric pump be before the mechanical fuel pump or after?

Yes, mine will be mounted between the tank and the mechanical pump. Here is a picture. I am still waiting on delivery from Summit

Nice pump. Built in filter, brackets hardware and the like. Something I have posted about before and need to do to my 2 cars.Yes, mine will be mounted between the tank and the mechanical pump. Here is a picture. I am still waiting on delivery from Summit

View attachment 1716066372

For you others that might be interested: Electric primer pump for fuel

TT5.9mag

Two atmospheres are better than one

Wiring on the switch should be simple. Power in, power out (constant), and power out (momentary). Pump will have a separate ground. So wire the hot side of the pump to both power out sides of the switch, 12v hot to power in, then ground the pump. Fuse the power in. Easy peasy lemon squeezey.

Yes, it was your original post that I was using as a reference, but the Airtex pump was not available. I found the same pump made by Carter which was available at Summit Racing.

67Dart273

Well-Known Member

I would NOT wire one switch "hot" AKA run it through the key at least, and use a relay.

Way too easy to bump a "always hot" switch and now you have fuel trying to push through the needle and seat plus run the battery down.

They make toggles that are momentary one direction and "latch" the other. If you get a SPDT (single pole double throw) it will have 3 terminals. Middle is common, one terminal will be momentary, the other will be latch. Wire the two outside terminals together and run them off to the relay coil Wire the center terminal to the "ignition run" terminal of the key through a small fuse.

Fuse the main power to the relay and run the load contact to the pump Be careful you get a solid ground connection for the pump

Way too easy to bump a "always hot" switch and now you have fuel trying to push through the needle and seat plus run the battery down.

They make toggles that are momentary one direction and "latch" the other. If you get a SPDT (single pole double throw) it will have 3 terminals. Middle is common, one terminal will be momentary, the other will be latch. Wire the two outside terminals together and run them off to the relay coil Wire the center terminal to the "ignition run" terminal of the key through a small fuse.

Fuse the main power to the relay and run the load contact to the pump Be careful you get a solid ground connection for the pump

One thing good about that pump is that the Min/max pressures are 3/6#.I would NOT wire one switch "hot" AKA run it through the key at least, and use a relay.

Way too easy to bump a "always hot" switch and now you have fuel trying to push through the needle and seat plus run the battery down.

They make toggles that are momentary one direction and "latch" the other. If you get a SPDT (single pole double throw) it will have 3 terminals. Middle is common, one terminal will be momentary, the other will be latch. Wire the two outside terminals together and run them off to the relay coil Wire the center terminal to the "ignition run" terminal of the key through a small fuse.

Fuse the main power to the relay and run the load contact to the pump Be careful you get a solid ground connection for the pump

Inertia

Well-Known Member

From a post of mine, - yrs ago.

If the vehicle has been sitting a while, the carb and lines may empty, but it is not nec to continue cranking till it fires ..

After 2 crankshaft revolutions the cams one revolution has cycled the pump's lever once, compressing a spring/diaphram inside the pump.

Stop cranking, wait a sec. and the spring/diaphram maintains suction for a few seconds moving fuel. Give it another short crank,wait a bit. - the lever once again cycles the pump, fuel moves after key released.

I usually gently pump throttle on 3 rd try, and it usually fires pretty quick.

An example, how often have you pulled/opened a fuel line to the carb after the engine hasn't run for a while, and got a spurt of fuel ?

That's the spring in the pump maintaining pressure to the carb, while it maintains vaccum to the tank . .

Really helps when you have a weak battery to understand pump function.

True on all manual diaphram pump vehicles to my knowledge.

Cheers .

If the vehicle has been sitting a while, the carb and lines may empty, but it is not nec to continue cranking till it fires ..

After 2 crankshaft revolutions the cams one revolution has cycled the pump's lever once, compressing a spring/diaphram inside the pump.

Stop cranking, wait a sec. and the spring/diaphram maintains suction for a few seconds moving fuel. Give it another short crank,wait a bit. - the lever once again cycles the pump, fuel moves after key released.

I usually gently pump throttle on 3 rd try, and it usually fires pretty quick.

An example, how often have you pulled/opened a fuel line to the carb after the engine hasn't run for a while, and got a spurt of fuel ?

That's the spring in the pump maintaining pressure to the carb, while it maintains vaccum to the tank . .

Really helps when you have a weak battery to understand pump function.

True on all manual diaphram pump vehicles to my knowledge.

Cheers .

Last edited:

Sorry, I should have mentioned that it was always my plan to use an ignition on power source.

jos51700

Green Bearing thread connoisseur

Then that pump is drawing power through what is likely some old-as-dirt wiring. I'm telling you....relay, and fresh wiring for that extra current. It's probably not great to pull that kind of load through a system that is, stock, marginal at best.Sorry, I should have mentioned that it was always my plan to use an ignition on power source.

67Dart273

Well-Known Member

Which is part of why I also said "use relay" The ignition / key supplied wiring is already on edgeThen that pump is drawing power through what is likely some old-as-dirt wiring. I'm telling you....relay, and fresh wiring for that extra current. It's probably not great to pull that kind of load through a system that is, stock, marginal at best.

Is there a Fuel Resistance thru the Electric Pump when it's off? Does the Mech Pump have to work harder after Primer is installed?

According to someone who has been using this same pump for over two years, it has not been an issue.

No. Those are rotary pumps that just freewheel when the fuel is pulled through.Is there a Fuel Resistance thru the Electric Pump when it's off? Does the Mech Pump have to work harder after Primer is installed?

I used a Holley mech diaphragm pump on my 440 Charger for years. It had an electric pump back at the tank that I only ran to prime the system before starting or when at the track racing. The electric was a Holley Red pump as I recall. It was never an issue with both pumps on the car. On the street, the electric pump was not turned on and never had any issues. At the track, the combo stayed no lower than 5-1/2 psi thru the lights.

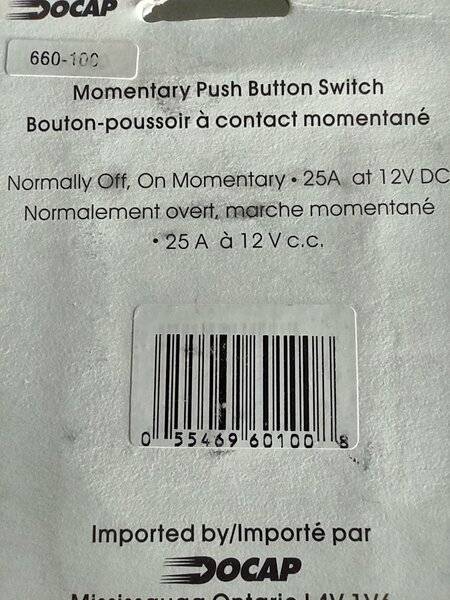

OK I picked up a heavy duty momentary switch on the way home, good for up to 25 amps. The good news is it will fit perfectly in the vacant hole for the parking brake warning light under the dash. The new plan, since it will only be used for priming when the button is pressed, is to wire it right off the battery positive through a 10 amp in line fuse, and bypass the ancient factory wiring. Probably won't satisfy some of you but should do the trick.

-