You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wiring priming fuel pump

- Thread starter qkcuda

- Start date

-

Use a Relay. So Simple. No Fire.

My worry with these set ups is this: the delivery volume of the mech pump is going to be reduced, having to 'suck' through the restriction of the elec pump. This volume reduction may not be a problem, but it could be on a performance engine that requires the max output of the mech pump.

BillGrissom

Well-Known Member

The Airtex Pump E8012S linked works for carburetors (8 psig max) and isn't pricey. Don't rely on a similar-looking EFI pump since those are positive displacement so will output >100 psig (or stall) without an outlet pressure regulator (all EFI systems have). That high pressure would force the carb needle open to overflow the bowl (dangerous). The little cubic rattle-pump linked also works.

A heavy-duty direct switch will work if rated for the pump current (no spec for Airtex?). The push-button seems best since no chance you will accidentally leave it on, though there are SPST toggle switches with one spring-loaded position. I might mount it underhood near the battery, since perhaps only used after sitting for months. To stay on in a roadside emergency, you might stash a jumper (easiest w/ Packard 56 spade terminals). "Might work" to plumb in series with the mechanical pump, or perhaps plumb parallel if the e-pump has an internal check valve (likely) like the mechanical pump.

For those running an e-pump full-time with carb, safest to install a 1970's Chevy oil pressure switch with 3 terminals: P = to pump, S = starter relay so pump runs while cranking, I = ignition so pump runs off IGN power as long as oil pressure is sufficient (>5 psig?). That will shut off the fuel pump if engine dies (no oil pressure). In my A's, I wired the dash oil warning lamp to "P" so that lamp lights when the pump is unpowered. Since my "P" routes to a relay coil, I use an LED dash bulb which doesn't pass enough current to actuate the relay. Not needed if you have EFI since those systems control the fuel pump, running it for 2 sec on initial power-up to pressurize the system, then actuates again once the engine is turning (per tach signal from spark coil). My two A's have a carb and high-pressure e-pump, for future EFI. To work with a carb, I routed the pump output back to the tank, which builds ~10 psig from just the pressure drop thru the 1/4" level sender stub. I then have an inline pressure reg to reduce to 5 psig at carb inlet. With later EFI, that allows swapping back to a carb with a quick underhood replumbing as roadside fix. Yes, I try to be ready for the zombie apocolypse, or at least avoid a $500 tow fee.

A heavy-duty direct switch will work if rated for the pump current (no spec for Airtex?). The push-button seems best since no chance you will accidentally leave it on, though there are SPST toggle switches with one spring-loaded position. I might mount it underhood near the battery, since perhaps only used after sitting for months. To stay on in a roadside emergency, you might stash a jumper (easiest w/ Packard 56 spade terminals). "Might work" to plumb in series with the mechanical pump, or perhaps plumb parallel if the e-pump has an internal check valve (likely) like the mechanical pump.

For those running an e-pump full-time with carb, safest to install a 1970's Chevy oil pressure switch with 3 terminals: P = to pump, S = starter relay so pump runs while cranking, I = ignition so pump runs off IGN power as long as oil pressure is sufficient (>5 psig?). That will shut off the fuel pump if engine dies (no oil pressure). In my A's, I wired the dash oil warning lamp to "P" so that lamp lights when the pump is unpowered. Since my "P" routes to a relay coil, I use an LED dash bulb which doesn't pass enough current to actuate the relay. Not needed if you have EFI since those systems control the fuel pump, running it for 2 sec on initial power-up to pressurize the system, then actuates again once the engine is turning (per tach signal from spark coil). My two A's have a carb and high-pressure e-pump, for future EFI. To work with a carb, I routed the pump output back to the tank, which builds ~10 psig from just the pressure drop thru the 1/4" level sender stub. I then have an inline pressure reg to reduce to 5 psig at carb inlet. With later EFI, that allows swapping back to a carb with a quick underhood replumbing as roadside fix. Yes, I try to be ready for the zombie apocolypse, or at least avoid a $500 tow fee.

Last edited:

bbab3

Well-Known Member

- Joined

- Feb 4, 2007

- Messages

- 294

- Reaction score

- 196

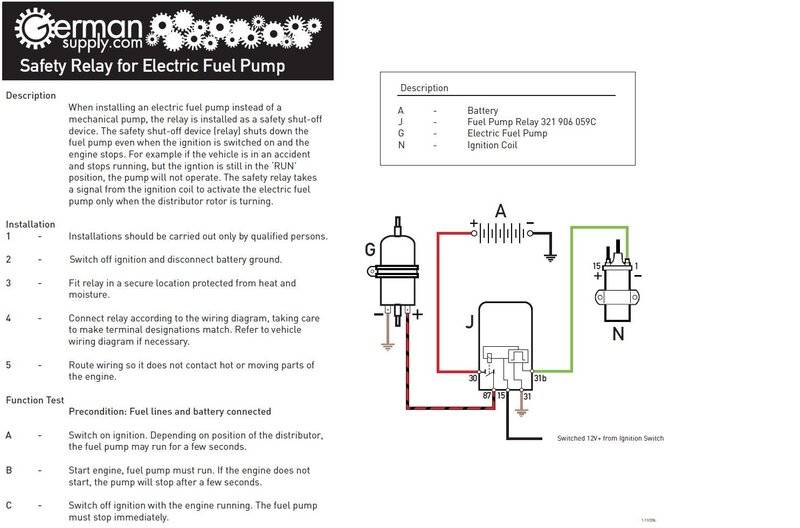

I have wired all electric fuel pumps like this. Running one in a off-road car can get real exciting when you’re upside down.

There's a lot of good information here especially the relay wiring and the safety senders and switches. I will say though, for a priming pump that you will energize for 5-10 seconds before starting cold, a lot of that is overkill. Direct battery feed through a fuse protected momentary switch would be fine. If you want to pull a signal through a switched circuit, I would use a relay but you will need to turn the ignition on to be able to run the pump. With my point type ignition cars I don't like to turn the key on for very long.

The only possible thing I can think of here is "if that switch sticks" and that seems highly unlikely. Should work fine.OK I picked up a heavy duty momentary switch on the way home, good for up to 25 amps. The good news is it will fit perfectly in the vacant hole for the parking brake warning light under the dash. The new plan, since it will only be used for priming when the button is pressed, is to wire it right off the battery positive through a 10 amp in line fuse, and bypass the ancient factory wiring. Probably won't satisfy some of you but should do the trick.

View attachment 1716066506

View attachment 1716066508

Thanks guys. Should be working on it tomorrow.

Here is the result. I actually had two problems to deal with, the fuel evaporation and a badly kinked fuel line. I think it either happened when the car was chained to a trailer, or when I tried to bend the pinch weld back into position. Before you tell me the pump should be mounted closer to the tank, I know. It is only for momentary use and is basically at the lowest point in the system. I still have to wire in the switch, but I ran out of time.

I finished wiring the momentary switch for the fuel pump. It was a challenge getting the switch into the existing hole under the dash because the main wiring loom to the fuse panel was right above the hole.

Looks good. It's going to work great. Don't forget to follow up after using it a few days.I finished wiring the momentary switch for the fuel pump. It was a challenge getting the switch into the existing hole under the dash because the main wiring loom to the fuse panel was right above the hole.

View attachment 1716072100

View attachment 1716072101

View attachment 1716072102

Thanks. It has been sitting all winter, so the first start should be a good test for it.

I haven't done it to mine (yet) but it would be nice to fill the carb and hit the key.Thanks. It has been sitting all winter, so the first start should be a good test for it.

-

Similar threads

- Replies

- 7

- Views

- 298