In this chapter I am going to go through installing the camshaft in the block... In the last chapter I showed you how to determine the compression of your combination... Now it's time to install the cam...

This is the next step to continue after Sections 1 - 7... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Ok, now that you have your crank, rods, and pistons installed in the block, it's time to install the camshaft - or cam for short...

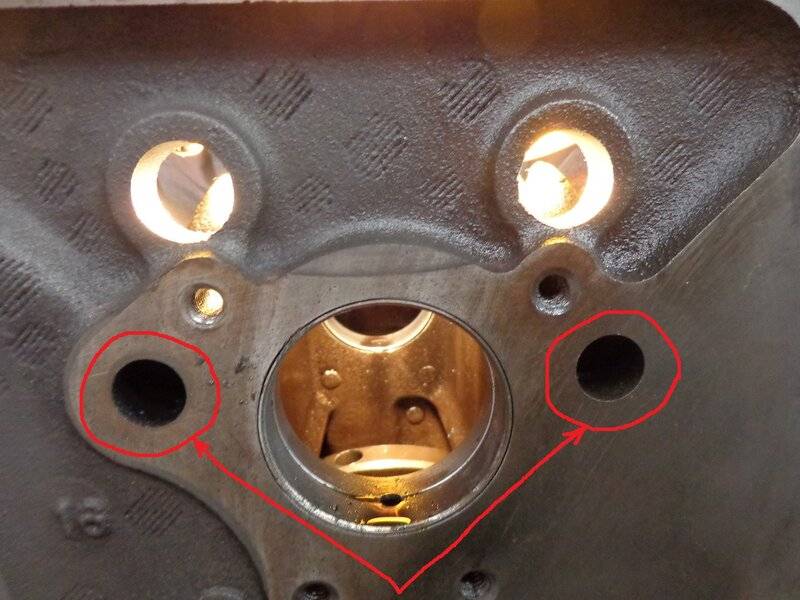

The first thing to do is verify that the oil galley plugs are installed for the lifter galleys... These are very important as the first engine that I built the machine shop did not install them and I had a low oil pressure problem... It would have 25 -30 psi oil pressure cold start and then drop down to 10 or less psi when it warmed up... I pulled the engine 4 times before finding the problem, so now I always double check to make sure they are installed... Sometimes the most important lessons are learned from your mistakes... I've had some people tell me that they are not important because the camshaft thrust plate covers them up, but my first experience proved to me that they are necessary... For those doubters, you build your engine the way that you want, but it's a small effort to install them to avoid oil pressure problems... I always make sure that my engines have them after that...

Here they are:

If they aren't installed, use a deep well socket a little smaller than the inside diameter of the cup plugs to install them in the proper holes... You install these without any sealant on them as you don't want any of it coming off and getting in the oil system and causing an interference... This is after the filter and any debris including a small ball of RTV can cause issues, so install these with some WD-40 or penetrating oil only to help them go in without galling...

If you don't have the proper cup plugs for the lifter galley, they come in either of these two cup plug packages from Mancini Racing, choose which one you want to use...

Mancini Racing Brass Freeze Plug Kit

This one is more expensive and comes with two more brass freeze plugs, but two less oil galley threaded plugs than the Mancini kit...

https://www.manciniracing.com/mibrfrplkit.html

It's a good idea to use a flat blade screwdriver after installing them and placing 4 'stakes' at 90° intervals around the diameter of the plugs to keep them good and tight...

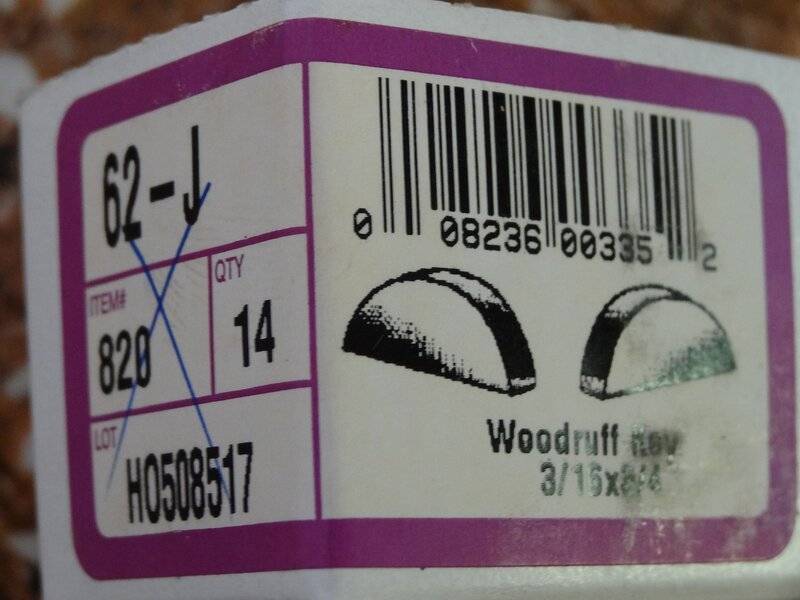

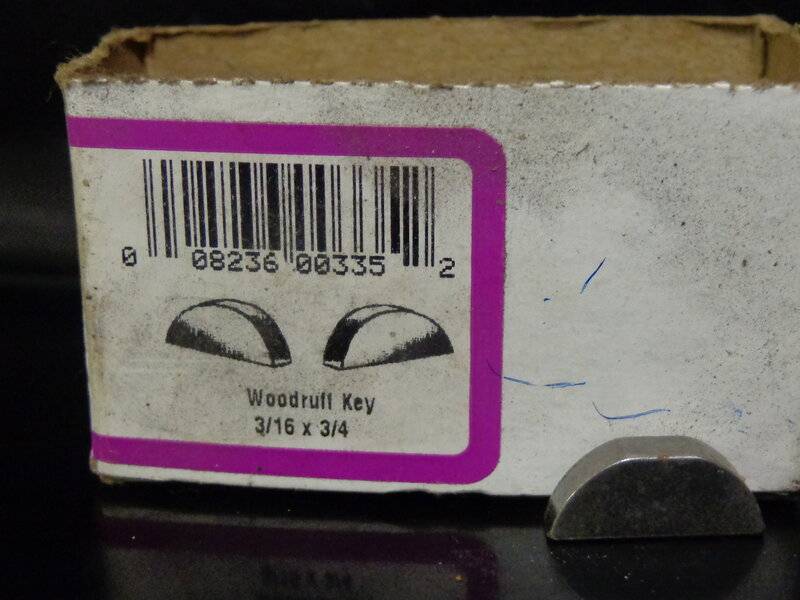

Now you have a brand new cam in the box and need to install the keyway or woodruff key in the slot for the timing gear... I bought a bunch of them for all of my cams and took the box from the hardware store that they came in for reference... I got these at my local Ace Hardware store in their fastener aisle and they are 3/16" x 3/4" long woodruff keys...

The whole box...

A close up of the side showing the part number for ordering...

The side of the box showing the description and one of the actual keyways next to the box so you can see what they look like...

The camshaft keyway also comes in a block hardware kit from Mancini Racing which also includes the timing chain oiling tab, crank keyway, head dowel pins, camshaft 'washer' and bolt, and thrust plate bolts...

Comp Cams Engine Finishing Kit

Take a small hammer and lightly tap the keyway into the slot in the camshaft making sure it bottoms out and the top part of the keyway is flat and even with the axis of the camshaft...

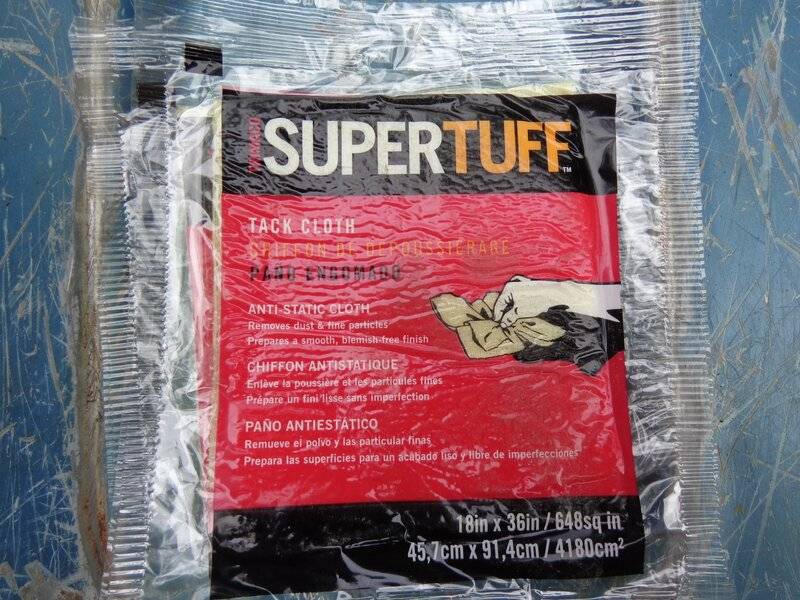

Now you need to clean it up before installing... Clean the camshaft journals and cam bearings with a good solvent, I like to use CRC Brakleen (the red chlorinated one works best) or Berryman's B-12... Then wipe them with a tack cloth to remove any dust/dirt/debris from them as these are bearing surfaces and need to be kept hospital clean... Any dust/dirt/fuzz can cause problems...

My favorite solvents:

Tack cloths:

Thick heavy lubricants, Motor Honey or STP... I prefer the Motor Honey, but both will do the job...

Now generously cover the camshaft bearings in the block and the camshaft journals on the cam to keep them lubed while you assemble the engine and then for the first start-up until the oil pump develops pressure and supplies the engine with oil...

Now you are ready to install the camshaft... I like to use the cam gear to help install the cam in the block as it provides extra leverage to help steer the cam through the tunnel... GO SLOW AND CAREFULLY AND GENTLY EASE THE CAM THROUGH ALL OF THE BEARINGS UNTIL IT'S FULLY INSTALLED!!! If you get too aggressive you can nick and damage the cam bearings...

Use your other hand on the back of the cam to help get it aligned as you guide it through each cam bearing through the block like this...

Now when you get to the last bearing in the back of the block with the rear journal of the camshaft, carefully line it up using the cam gear to help steer it in and then gently press it into the rear bearing...

The cam should be fully installed like this...

Now the camshaft is installed and you are ready to move on to installing the camshaft thrust plate...

This is the next step to continue after Sections 1 - 7... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Ok, now that you have your crank, rods, and pistons installed in the block, it's time to install the camshaft - or cam for short...

The first thing to do is verify that the oil galley plugs are installed for the lifter galleys... These are very important as the first engine that I built the machine shop did not install them and I had a low oil pressure problem... It would have 25 -30 psi oil pressure cold start and then drop down to 10 or less psi when it warmed up... I pulled the engine 4 times before finding the problem, so now I always double check to make sure they are installed... Sometimes the most important lessons are learned from your mistakes... I've had some people tell me that they are not important because the camshaft thrust plate covers them up, but my first experience proved to me that they are necessary... For those doubters, you build your engine the way that you want, but it's a small effort to install them to avoid oil pressure problems... I always make sure that my engines have them after that...

Here they are:

If they aren't installed, use a deep well socket a little smaller than the inside diameter of the cup plugs to install them in the proper holes... You install these without any sealant on them as you don't want any of it coming off and getting in the oil system and causing an interference... This is after the filter and any debris including a small ball of RTV can cause issues, so install these with some WD-40 or penetrating oil only to help them go in without galling...

If you don't have the proper cup plugs for the lifter galley, they come in either of these two cup plug packages from Mancini Racing, choose which one you want to use...

Mancini Racing Brass Freeze Plug Kit

This one is more expensive and comes with two more brass freeze plugs, but two less oil galley threaded plugs than the Mancini kit...

https://www.manciniracing.com/mibrfrplkit.html

It's a good idea to use a flat blade screwdriver after installing them and placing 4 'stakes' at 90° intervals around the diameter of the plugs to keep them good and tight...

Now you have a brand new cam in the box and need to install the keyway or woodruff key in the slot for the timing gear... I bought a bunch of them for all of my cams and took the box from the hardware store that they came in for reference... I got these at my local Ace Hardware store in their fastener aisle and they are 3/16" x 3/4" long woodruff keys...

The whole box...

A close up of the side showing the part number for ordering...

The side of the box showing the description and one of the actual keyways next to the box so you can see what they look like...

The camshaft keyway also comes in a block hardware kit from Mancini Racing which also includes the timing chain oiling tab, crank keyway, head dowel pins, camshaft 'washer' and bolt, and thrust plate bolts...

Comp Cams Engine Finishing Kit

Take a small hammer and lightly tap the keyway into the slot in the camshaft making sure it bottoms out and the top part of the keyway is flat and even with the axis of the camshaft...

Now you need to clean it up before installing... Clean the camshaft journals and cam bearings with a good solvent, I like to use CRC Brakleen (the red chlorinated one works best) or Berryman's B-12... Then wipe them with a tack cloth to remove any dust/dirt/debris from them as these are bearing surfaces and need to be kept hospital clean... Any dust/dirt/fuzz can cause problems...

My favorite solvents:

Tack cloths:

Thick heavy lubricants, Motor Honey or STP... I prefer the Motor Honey, but both will do the job...

Now generously cover the camshaft bearings in the block and the camshaft journals on the cam to keep them lubed while you assemble the engine and then for the first start-up until the oil pump develops pressure and supplies the engine with oil...

Now you are ready to install the camshaft... I like to use the cam gear to help install the cam in the block as it provides extra leverage to help steer the cam through the tunnel... GO SLOW AND CAREFULLY AND GENTLY EASE THE CAM THROUGH ALL OF THE BEARINGS UNTIL IT'S FULLY INSTALLED!!! If you get too aggressive you can nick and damage the cam bearings...

Use your other hand on the back of the cam to help get it aligned as you guide it through each cam bearing through the block like this...

Now when you get to the last bearing in the back of the block with the rear journal of the camshaft, carefully line it up using the cam gear to help steer it in and then gently press it into the rear bearing...

The cam should be fully installed like this...

Now the camshaft is installed and you are ready to move on to installing the camshaft thrust plate...