The heater motor is actually a Stock Motor that I have recessed into a modified heater box housing.

Here are the steps to do the heater box modification.

1 - Remove heater box from the car.

2 - Place heater box face down on a towel or soft surface with the motor facing up.

3 - Find a drill bit JUST SLIGHTLY larger then the small rivets that hold the sheet metal back to the fiberglass housing. (1/8" I think)

4 - Carefully drill out all of the rivets, dispose of them and remove the sheet metal back.

5 - You will find that the heater motor is held on to the heater box mounting bolts on the rear plate by four nuts.

5.1 - The mount studs SHOULD each have a small spacer tube on them , remove and save them and the four nuts for use on reassembly.

5.2 - Remove the four nuts that retain the heater motor and remove the motor and squirrel cage fan assembly and carefully set aside. Be careful that you do not bend or damage the fan.

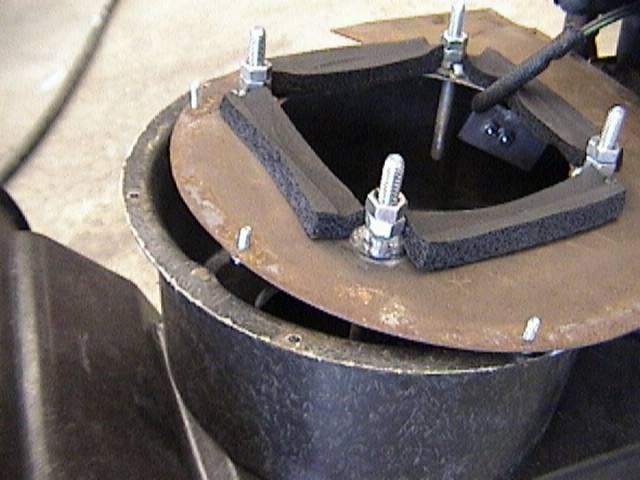

6 - You should now have a flat piece of sheet metal with a hole for the fan and four studs for mounting the fan.

7 - Now take the sheet metal back and turn it over. You will see the original mounting studs are spot welded on to the back. Find four 1/4" X 1" bolts with threads all the way to the head of the bolt and center one bolt on top of the head of each of the original mounting studs and weld them in place. Let cool then proceed to next step.

8 - Now take two or three 1/4" nuts and thread them all of the way to the head of each of the bolts you just welded on. These are used to space the fan assembly away from the back plate the desired distance. I believe that I used three nuts on my final assembly.

The motor set back can be varied by the number of spacer nuts used. Just be careful not to space it to far in or you WILL hit the heater core

Find some 1/2" wide self adhesive weather strip and cut to length and place between the bolts to seal the motor to the plate. (you may have to stack the weather strip for a good seal)

9 - Now place the fan assembly on to the bolts and use four more nuts to hold it in place. The fan should now be on the BACK side of the sheet plate.

10 - Now take a high speed die grinder and bit and enlarge the cone shaped hole in the heater box to about 1/2" larger then the squirrel cage fan diameter. You want between 1/8" and 1/4" clearance all around.

11 - Now find seven 6 X 32 X 3/8" machine screws and seven 6 X 32 Nyloc nuts. Enlarge the holes in the plate and heater housing just enough for the screws to fit and put the screws in from the sheet metal side and the nuts on the fiberglass side and reassemble the sheet metal plate to the fiberglass housing.

12 - Now place the four spacers over the original studs and a nut on each and put the heater box back in the car. DO NOT add more spacers here or the heater box will not line up and seal with the vent hole in the cowl. Now is a good time to replace the weather-strip between the heater box and cowl if it is damaged or compressed too much.

]

]

While you have the heater box out and apart, add a reinforcement to the cable control mounts by drilling or grinding the rivets out/off and cutting and drilling a 1/8" X 1" steel or aluminum strap to match the rivet holes. replace the rivets with 6 X 32 machine screws and nyloc nuts, put the plate on the inside of the box and tighten things up. This will keep the cable mounts from breaking off at the most inopportune time.

I have been running this modification for over six years now and it works and heats great.

I hope this will help a few people with their heater motor and valve cover clearance troubles.

Herb - Dart67

Here are the steps to do the heater box modification.

1 - Remove heater box from the car.

2 - Place heater box face down on a towel or soft surface with the motor facing up.

3 - Find a drill bit JUST SLIGHTLY larger then the small rivets that hold the sheet metal back to the fiberglass housing. (1/8" I think)

4 - Carefully drill out all of the rivets, dispose of them and remove the sheet metal back.

5 - You will find that the heater motor is held on to the heater box mounting bolts on the rear plate by four nuts.

5.1 - The mount studs SHOULD each have a small spacer tube on them , remove and save them and the four nuts for use on reassembly.

5.2 - Remove the four nuts that retain the heater motor and remove the motor and squirrel cage fan assembly and carefully set aside. Be careful that you do not bend or damage the fan.

6 - You should now have a flat piece of sheet metal with a hole for the fan and four studs for mounting the fan.

7 - Now take the sheet metal back and turn it over. You will see the original mounting studs are spot welded on to the back. Find four 1/4" X 1" bolts with threads all the way to the head of the bolt and center one bolt on top of the head of each of the original mounting studs and weld them in place. Let cool then proceed to next step.

8 - Now take two or three 1/4" nuts and thread them all of the way to the head of each of the bolts you just welded on. These are used to space the fan assembly away from the back plate the desired distance. I believe that I used three nuts on my final assembly.

The motor set back can be varied by the number of spacer nuts used. Just be careful not to space it to far in or you WILL hit the heater core

Find some 1/2" wide self adhesive weather strip and cut to length and place between the bolts to seal the motor to the plate. (you may have to stack the weather strip for a good seal)

9 - Now place the fan assembly on to the bolts and use four more nuts to hold it in place. The fan should now be on the BACK side of the sheet plate.

10 - Now take a high speed die grinder and bit and enlarge the cone shaped hole in the heater box to about 1/2" larger then the squirrel cage fan diameter. You want between 1/8" and 1/4" clearance all around.

11 - Now find seven 6 X 32 X 3/8" machine screws and seven 6 X 32 Nyloc nuts. Enlarge the holes in the plate and heater housing just enough for the screws to fit and put the screws in from the sheet metal side and the nuts on the fiberglass side and reassemble the sheet metal plate to the fiberglass housing.

12 - Now place the four spacers over the original studs and a nut on each and put the heater box back in the car. DO NOT add more spacers here or the heater box will not line up and seal with the vent hole in the cowl. Now is a good time to replace the weather-strip between the heater box and cowl if it is damaged or compressed too much.

While you have the heater box out and apart, add a reinforcement to the cable control mounts by drilling or grinding the rivets out/off and cutting and drilling a 1/8" X 1" steel or aluminum strap to match the rivet holes. replace the rivets with 6 X 32 machine screws and nyloc nuts, put the plate on the inside of the box and tighten things up. This will keep the cable mounts from breaking off at the most inopportune time.

I have been running this modification for over six years now and it works and heats great.

I hope this will help a few people with their heater motor and valve cover clearance troubles.

Herb - Dart67