Well no, you did it. You cleaned the connection "enough" when you disconnected it. I would disconnect it again and clean all the brass terminals best you can. Now you see why we always say those firewall connectors can be the devil. lolok, it must have been a dirty connection or a loose one or something because I just cranked it up and it sat and idled fine. it fixed itelf

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I put it into gear and it dies.

- Thread starter shittyslant6

- Start date

-

That's how the resistor works. When current flows through, voltage drops and heat is created.Specifically, 5.8v (and 5.2v at the coil) on the side with the brown and the blue on it. and 10.78v on the side with only the blue wire. and the test light lights up at both sides of the bulkhead and there is power going into the switch.

WHAT.

With the key in run and the points closed in the distributor, current flows through the ballast. On the run side its system voltage, on the other side its something less. 10.8 Volts is kindof low. Maybe the battery is low but maybe not. Next time you test that, go quickly measure the battery at the same time. A tenth or two is no big deal. A full volt between the battery (or alternator) and the run wires indicates poor connections.

Firewall connector or column connector? Regardless, clean them up and make sure the metal terminals inside aren't backing out.Ok so before when I was checking voltage at the ballast with that rigging above, the test light only lit up in the specific spot in crank. NOW, after only unplugging the connector before the switch and plugging it back in, the ballast has power.

shittyslant6

Well-Known Member

Yes. Ballast is taking battery voltage down to whatever it is at the coil so it will be hot. If it now miraculously now runs, you had a dirty firewall connector. I would remove it and clean it as best you can.

no, not the bulkhead connector, I disconnected the pin connector the ignition switch wires go into.Well no, you did it. You cleaned the connection "enough" when you disconnected it. I would disconnect it again and clean all the brass terminals best you can. Now you see why we always say those firewall connectors can be the devil. lol

I just touched the bulkhead connectors with the probe and it lit up the test light.

I would like to take out the bulkhead connector and clean them all, but when I tried to do that before, it would not come out and in the interest of not breaking it, (since it is 50 year old plastic) I stopped.

Yeah, I would go through every dang connector on that car now and start cleanin. That was one of the first things I did when we dragged Vixen home, because I KNEW from experience and from reading all the info here that it was a point of contention. So far, I've not had one minute's trouble. Fingers crossed.That's how the resistor works. When current flows through, voltage drops and heat is created.

With the key in run and the points closed in the distributor, current flows through the ballast. On the run side its system voltage, on the other side its something less. 10.8 Volts is kindof low. Maybe the battery is low but maybe not. Next time you test that, go quickly measure the battery at the same time. A tenth or two is no big deal. A full volt between the battery (or alternator) and the run wires indicates poor connections.

Firewall connector or column connector? Regardless, clean them up and make sure the metal terminals inside aren't backing out.

Gotchya. You could have very well wiggled the back side of the ignition switch enough to restore the connection. In any event, it won't hurt a thing to take some time cleaning all those connections, I don't believe.no, not the bulkhead connector, I disconnected the pin connector the ignition switch wires go into.

I just touched the bulkhead connectors with the probe and it lit up the test light.

I would like to take out the bulkhead connector and clean them all, but when I tried to do that before, it would not come out and in the interest of not breaking it, (since it is 50 year old plastic) I stopped.

Column shift?no, not the bulkhead connector, I disconnected the pin connector the ignition switch wires go into.

I just touched the bulkhead connectors with the probe and it lit up the test light.

I would like to take out the bulkhead connector and clean them all, but when I tried to do that before, it would not come out and in the interest of not breaking it, (since it is 50 year old plastic) I stopped.

shittyslant6

Well-Known Member

ok, i will try and clean out the connections starting at the easiest to get to then I will try again with the bulkhead.Gotchya. You could have very well wiggled the back side of the ignition switch enough to restore the connection. In any event, it won't hurt a thing to take some time cleaning all those connections, I don't believe.

I'll be working on it the whole 3-day weekend so hopefully we can get ALL the issues so far solved.

the big one still being it not wanting to drive.

shittyslant6

Well-Known Member

yesColumn shift?

That connector on the column is pretty critical. Do that first since you know its a problem.ok, i will try and clean out the connections starting at the easiest to get to then I will try again with the bulkhead.

I'll be working on it the whole 3-day weekend so hopefully we can get ALL the issues so far solved.

the big one still being it not wanting to drive.

Do you know how those round terminals are held in there? and how to get them out and reinstalled?

Here's the thing about a poor connection on either the J2 (run) or the J1 (feed) wire.

a. resistance causes heat. You just experienced that! LOL

b. A voltage drop in those lines will cause the voltage regulator to see a low voltage when the engine is running. It will then work to bring system voltage up. Then you'll have an alternator running at 15.5 Volts, and if the connections to other stuff like the battery and headlights are good, that's what they'll see.

shittyslant6

Well-Known Member

ok, so i did check the battery at the same time, at it was at 12.3v. so that just further proves that bad connections are the problem.That's how the resistor works. When current flows through, voltage drops and heat is created.

With the key in run and the points closed in the distributor, current flows through the ballast. On the run side its system voltage, on the other side its something less. 10.8 Volts is kindof low. Maybe the battery is low but maybe not. Next time you test that, go quickly measure the battery at the same time. A tenth or two is no big deal. A full volt between the battery (or alternator) and the run wires indicates poor connections.

Firewall connector or column connector? Regardless, clean them up and make sure the metal terminals inside aren't backing out.

They've got little barbs on them. You'll need a tubular removal tool to take them out.

Some photos here.

Sources for Chrysler type wire terminals

A big thing is to make sure they are not backing out on their own.

I've not had that on the round terminals but others have.

I have had it on the Packard 56/58/59 type of terminals and others. Push the connector in and all looks cood but the metal is hardly touching if at all. Pull your hair out trying to figure out an intermittant problem and everything looks good. Had it on the Ford type coil connector and GM alternator connector. Must be a Jeep thing.

Some photos here.

Sources for Chrysler type wire terminals

A big thing is to make sure they are not backing out on their own.

I've not had that on the round terminals but others have.

I have had it on the Packard 56/58/59 type of terminals and others. Push the connector in and all looks cood but the metal is hardly touching if at all. Pull your hair out trying to figure out an intermittant problem and everything looks good. Had it on the Ford type coil connector and GM alternator connector. Must be a Jeep thing.

Last edited:

If with key in run it was 12.3 at the battery at the same time it was 10.8 at the ballast, yes that's alot.ok, so i did check the battery at the same time, at it was at 12.3v. so that just further proves that bad connections are the problem.

1.5 Volt with just a couple amps trying to get through.

If 12.3v at the battery was measured with no load, then the battery is on the way out. Might be worth buying a new battery before it fails when you are away from home.

If you had read more than a random line, you'ld know he'ld been f'in around looking for an open in the run circuit.

Regardless, before someone runs out and buys a battery, the first thing to do is use one of these.

67Dart273

Well-Known Member

This thread is another great example of WHY I OFTEN MENTION "THE PATH." It equates to a hike in the woods, or established trails and roads. "THE PATH."

I usually start at the battery because that is a definitive 'point.' I do realize that current flows from neg to pos (electron flow) but "the path" is still a CIRCLE, so it does not matter which direction you go to describe it.

THE PATH.

Identify what is failing (in this case the ignition) and establish the path from battery to the problem and then troubleshoot the ENTIRE path.

WHAT IS the path "to the coil?" It is from the battery, through EVERY SINGLE CONNECTOR AND TERMINAL AND SWITCH to the coil PLUS (if that is what you have proved is losing power)

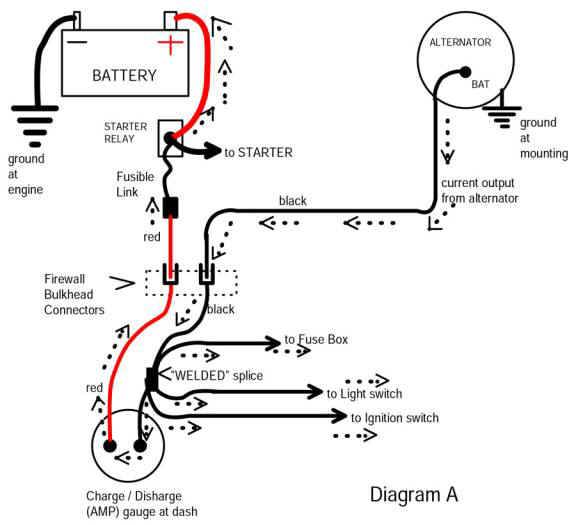

The one diagram which should be emblazoned in every Mopar owner's mind, is the simplified MAD diagram in their article: (because it is so bold and simple)

This gets you as far as "almost" to the ignition switch...........

WHAT is the rest of "the path?"

From the feed to the ignition switch goes to the switch CONNECTOR (there's a terminal in there) and so that terminal and the connection to the switch infeed is ONE MORE point that can cause a drop / poor connection

Through the switch (CONTACTS)---another drop point

Out the switch connector on the "run" wire (dark blue IGN1) ANOTHER drop point terminal

And to and through the BULKHEAD CONNECTOR (dark blue run wire)--another drop point

And out into the harness and to the ballast connector (ANOTHER drop point)

You must chase this back down the PATH and measure each point "you can get to" and if you can't find it, then "get to" the places you didn't check before.

OTHER THINGS IN THE PATH

What about the black ammeter wire / welded splice? WELDED!!! Well guess what, in my lifetime, and now some of them from the guys right here, I've been privy to about a dozen FAILED welded splices over the years. Poorly welded, corroded, burned open, who knows? They can FAIL

AMMETER. The ammeter itself develops problems and the WIRE TERMINALS on the black and red ammeter wires can fail. Right there is about FOUR fail points

BULKHEAD CONNECTOR....Here you have a "bouquet" of failure. Not only can the AMMETER circuit terminals fail, because of heavy load, age, corrosion, oxidation, heat damage, but.......

Any other circuit in there with "much of a load" can fail...........The red ammeter wire, the black charge wire, the dark blue "run" circuit, the high and low headlights circuit................................

If it helps, sit down, get out the FSM and draw the part of the circuit you are chasing, with all the terminals and switches noted. And then when you check them DO SO CAREFULLY

Once you find with a test lamp that you have a "fail," go back with a METER and get more specific, and more carefully MEASURE the actual voltage COMPARED TO THE BATTERY

CURRENT. Never forget that CURRENT FLOW (or lack of it) can send you down the rosy path of mis-information. CURRENT and a voltmeter can be a huge friend in troubleshooting.

EXAMPLE

You, here have a power fail to the ignition. "Let's say" you check and it seems OK, you have power, WTF!! DO you? WHAT IF YOU have checked this AND THE breaker points are OPEN?

With the points open, there is NO current flow through the coil. There is no LOAD on that circuit. You might measure what you think is normal voltage to the ballast, and yet "it won't run."

.............And then you happen to check with the points closed.........and the coil reads............ZERO. WHY? You "had" power, right? Wrong. The failure in the harness maybe worked "fine" without the added load of the coil drawing current. When the points closed, it LOADED the circuit and the bad terminal fizzled "open" and the voltage went .................."poof."

................This is no different, than, say, a bad battery post connection.........You turn on the headlights and they work GREAT!!! And then you try and start the car and...........clickety buzz de clicky de plzzzzzzzzsssssstttttttttttttttttttttttttttttt!!!! WHAT!? Headlights worked!!! WTF

The connection was just good enough to operate the lights but not the starter

Just a few random thoughts.

I usually start at the battery because that is a definitive 'point.' I do realize that current flows from neg to pos (electron flow) but "the path" is still a CIRCLE, so it does not matter which direction you go to describe it.

THE PATH.

Identify what is failing (in this case the ignition) and establish the path from battery to the problem and then troubleshoot the ENTIRE path.

WHAT IS the path "to the coil?" It is from the battery, through EVERY SINGLE CONNECTOR AND TERMINAL AND SWITCH to the coil PLUS (if that is what you have proved is losing power)

The one diagram which should be emblazoned in every Mopar owner's mind, is the simplified MAD diagram in their article: (because it is so bold and simple)

This gets you as far as "almost" to the ignition switch...........

WHAT is the rest of "the path?"

From the feed to the ignition switch goes to the switch CONNECTOR (there's a terminal in there) and so that terminal and the connection to the switch infeed is ONE MORE point that can cause a drop / poor connection

Through the switch (CONTACTS)---another drop point

Out the switch connector on the "run" wire (dark blue IGN1) ANOTHER drop point terminal

And to and through the BULKHEAD CONNECTOR (dark blue run wire)--another drop point

And out into the harness and to the ballast connector (ANOTHER drop point)

You must chase this back down the PATH and measure each point "you can get to" and if you can't find it, then "get to" the places you didn't check before.

OTHER THINGS IN THE PATH

What about the black ammeter wire / welded splice? WELDED!!! Well guess what, in my lifetime, and now some of them from the guys right here, I've been privy to about a dozen FAILED welded splices over the years. Poorly welded, corroded, burned open, who knows? They can FAIL

AMMETER. The ammeter itself develops problems and the WIRE TERMINALS on the black and red ammeter wires can fail. Right there is about FOUR fail points

BULKHEAD CONNECTOR....Here you have a "bouquet" of failure. Not only can the AMMETER circuit terminals fail, because of heavy load, age, corrosion, oxidation, heat damage, but.......

Any other circuit in there with "much of a load" can fail...........The red ammeter wire, the black charge wire, the dark blue "run" circuit, the high and low headlights circuit................................

If it helps, sit down, get out the FSM and draw the part of the circuit you are chasing, with all the terminals and switches noted. And then when you check them DO SO CAREFULLY

Once you find with a test lamp that you have a "fail," go back with a METER and get more specific, and more carefully MEASURE the actual voltage COMPARED TO THE BATTERY

CURRENT. Never forget that CURRENT FLOW (or lack of it) can send you down the rosy path of mis-information. CURRENT and a voltmeter can be a huge friend in troubleshooting.

EXAMPLE

You, here have a power fail to the ignition. "Let's say" you check and it seems OK, you have power, WTF!! DO you? WHAT IF YOU have checked this AND THE breaker points are OPEN?

With the points open, there is NO current flow through the coil. There is no LOAD on that circuit. You might measure what you think is normal voltage to the ballast, and yet "it won't run."

.............And then you happen to check with the points closed.........and the coil reads............ZERO. WHY? You "had" power, right? Wrong. The failure in the harness maybe worked "fine" without the added load of the coil drawing current. When the points closed, it LOADED the circuit and the bad terminal fizzled "open" and the voltage went .................."poof."

................This is no different, than, say, a bad battery post connection.........You turn on the headlights and they work GREAT!!! And then you try and start the car and...........clickety buzz de clicky de plzzzzzzzzsssssstttttttttttttttttttttttttttttt!!!! WHAT!? Headlights worked!!! WTF

The connection was just good enough to operate the lights but not the starter

Just a few random thoughts.

shittyslant6

Well-Known Member

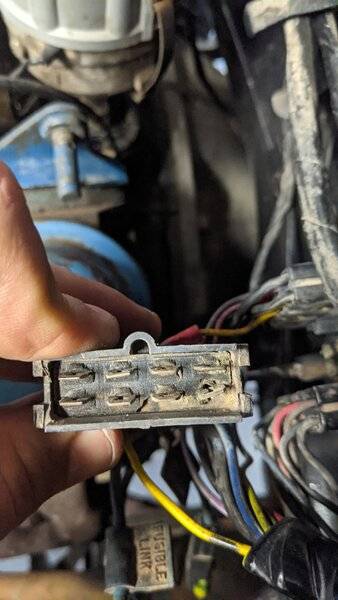

So I have some news. I am cleaning out all the connectors under the hood and it has been going smoothly, every single connection so far I have touched (that I did not put new ends on) have been white with corrosion. So I got to the first bulkhead connector and it was filled with dirt, corrosion, etc, and I was able to make all the connections in there shiny and new almost. good.

Now I pulled off the center connector and something is a little bit fucky;

As you can see, the clips are broken off and the bottom fusible link terminal is twisted sideways and some of the plastic has been broken off. (someone has been in here before.) But my biggest issue is on the top right. That fusible link connector on the bulkhead is not even there and there is no wire on the other side.

Is that normal?

because if not, that is my whole issue.

Now I pulled off the center connector and something is a little bit fucky;

As you can see, the clips are broken off and the bottom fusible link terminal is twisted sideways and some of the plastic has been broken off. (someone has been in here before.) But my biggest issue is on the top right. That fusible link connector on the bulkhead is not even there and there is no wire on the other side.

Is that normal?

because if not, that is my whole issue.

shittyslant6

Well-Known Member

you should write a book. just a book with all the information in you head. goddamn.This thread is another great example of WHY I OFTEN MENTION "THE PATH." It equates to a hike in the woods, or established trails and roads. "THE PATH."

I usually start at the battery because that is a definitive 'point.' I do realize that current flows from neg to pos (electron flow) but "the path" is still a CIRCLE, so it does not matter which direction you go to describe it.

THE PATH.

Identify what is failing (in this case the ignition) and establish the path from battery to the problem and then troubleshoot the ENTIRE path.

WHAT IS the path "to the coil?" It is from the battery, through EVERY SINGLE CONNECTOR AND TERMINAL AND SWITCH to the coil PLUS (if that is what you have proved is losing power)

The one diagram which should be emblazoned in every Mopar owner's mind, is the simplified MAD diagram in their article: (because it is so bold and simple)

View attachment 1715853307

This gets you as far as "almost" to the ignition switch...........

WHAT is the rest of "the path?"

From the feed to the ignition switch goes to the switch CONNECTOR (there's a terminal in there) and so that terminal and the connection to the switch infeed is ONE MORE point that can cause a drop / poor connection

Through the switch (CONTACTS)---another drop point

Out the switch connector on the "run" wire (dark blue IGN1) ANOTHER drop point terminal

And to and through the BULKHEAD CONNECTOR (dark blue run wire)--another drop point

And out into the harness and to the ballast connector (ANOTHER drop point)

You must chase this back down the PATH and measure each point "you can get to" and if you can't find it, then "get to" the places you didn't check before.

OTHER THINGS IN THE PATH

What about the black ammeter wire / welded splice? WELDED!!! Well guess what, in my lifetime, and now some of them from the guys right here, I've been privy to about a dozen FAILED welded splices over the years. Poorly welded, corroded, burned open, who knows? They can FAIL

AMMETER. The ammeter itself develops problems and the WIRE TERMINALS on the black and red ammeter wires can fail. Right there is about FOUR fail points

BULKHEAD CONNECTOR....Here you have a "bouquet" of failure. Not only can the AMMETER circuit terminals fail, because of heavy load, age, corrosion, oxidation, heat damage, but.......

Any other circuit in there with "much of a load" can fail...........The red ammeter wire, the black charge wire, the dark blue "run" circuit, the high and low headlights circuit................................

If it helps, sit down, get out the FSM and draw the part of the circuit you are chasing, with all the terminals and switches noted. And then when you check them DO SO CAREFULLY

Once you find with a test lamp that you have a "fail," go back with a METER and get more specific, and more carefully MEASURE the actual voltage COMPARED TO THE BATTERY

CURRENT. Never forget that CURRENT FLOW (or lack of it) can send you down the rosy path of mis-information. CURRENT and a voltmeter can be a huge friend in troubleshooting.

EXAMPLE

You, here have a power fail to the ignition. "Let's say" you check and it seems OK, you have power, WTF!! DO you? WHAT IF YOU have checked this AND THE breaker points are OPEN?

With the points open, there is NO current flow through the coil. There is no LOAD on that circuit. You might measure what you think is normal voltage to the ballast, and yet "it won't run."

.............And then you happen to check with the points closed.........and the coil reads............ZERO. WHY? You "had" power, right? Wrong. The failure in the harness maybe worked "fine" without the added load of the coil drawing current. When the points closed, it LOADED the circuit and the bad terminal fizzled "open" and the voltage went .................."poof."

................This is no different, than, say, a bad battery post connection.........You turn on the headlights and they work GREAT!!! And then you try and start the car and...........clickety buzz de clicky de plzzzzzzzzsssssstttttttttttttttttttttttttttttt!!!! WHAT!? Headlights worked!!! WTF

The connection was just good enough to operate the lights but not the starter

Just a few random thoughts.

shittyslant6

Well-Known Member

ok so after the whole day of cleaning up the bulkhead contacts, I have reduced ever so slightly the resistance and I have found the point of the most resistance.

after i did some poking around, I figured out that at the igniton switch connector before the column, blue tr. wire (J2) had 11.63v. Then at the interior side of the bulkhead it had 11.53v. on the engine side of the bulkhead the blue tr. wire had 10.6v. So even after the cleaning of the bulkhead, it is still knocking the voltage down .97v.

crap.

I am thinking of bypassing that connection and just connecting the wires together through an open hole in the bulkhead.

after i did some poking around, I figured out that at the igniton switch connector before the column, blue tr. wire (J2) had 11.63v. Then at the interior side of the bulkhead it had 11.53v. on the engine side of the bulkhead the blue tr. wire had 10.6v. So even after the cleaning of the bulkhead, it is still knocking the voltage down .97v.

crap.

I am thinking of bypassing that connection and just connecting the wires together through an open hole in the bulkhead.

You don't even need to do that. Just USE the bulkhead connector. Remove the terminals from it and drill out both sides of the connector so the wires can pass right through. That way, you're not adding any holes, you're using what's there.ok so after the whole day of cleaning up the bulkhead contacts, I have reduced ever so slightly the resistance and I have found the point of the most resistance.

after i did some poking around, I figured out that at the igniton switch connector before the column, blue tr. wire (J2) had 11.63v. Then at the interior side of the bulkhead it had 11.53v. on the engine side of the bulkhead the blue tr. wire had 10.6v. So even after the cleaning of the bulkhead, it is still knocking the voltage down .97v.

crap.

I am thinking of bypassing that connection and just connecting the wires together through an open hole in the bulkhead.

shittyslant6

Well-Known Member

yeah, since my car has ZERO options there are left over holes in the bulkhead. I was just going to use one of thoseYou don't even need to do that. Just USE the bulkhead connector. Remove the terminals from it and drill out both sides of the connector so the wires can pass right through. That way, you're not adding any holes, you're using what's there.

Or you could buy a new middle connector and some new terminals.

Depends on how serviceable you want to make it and well sealled.

DMT makes sells the seals.

Either way, I'd pop all the metal terminals out and clean them.

Maybe you've seen these, but if you haven't.

A bit of Wiring 101

What do y'all use to clean the metal connectors that go into the bulkhead on either side of the fw?

There's more threads you can look for including a few on splices. All pretty good IIRC.

Depends on how serviceable you want to make it and well sealled.

DMT makes sells the seals.

Either way, I'd pop all the metal terminals out and clean them.

Maybe you've seen these, but if you haven't.

A bit of Wiring 101

What do y'all use to clean the metal connectors that go into the bulkhead on either side of the fw?

There's more threads you can look for including a few on splices. All pretty good IIRC.

Last edited:

shittyslant6

Well-Known Member

how do you pop them out? just push on them from the front?Or you could buy a new middle connector and some new terminals.

Depends on how serviceable you want to make it and well sealled.

DMT makes sells the seals.

Either way, I'd pop all the metal terminals out and clean them.

Use a grommet. That was done a few years and also as an option. Those still had a connector the locked the wires together. Usually a round type like a Molex.yeah, since my car has ZERO options there are left over holes in the bulkhead. I was just going to use one of those

The one on the right will get you through most of the terminals on the car.

Lisle 56500 Terminal Tool Removes Wires | eBay

Or ypu cam buy a complet kit that has individual terminal tools around $50

how do you pop them out? just push on them from the front?

The female terminals have a barb on the backs.

To remove the females, use a flattened cotter pin, tiny screw driver, or the tool they make for it to depress the tab while pushing it out.

Those above are Packard 56 but Chrysler ones work the same way/

Sometimes they are interchangable. Sometimes not and they won't fit in or they will be too loose in the connector made for the other.

When installing them make sure the locking tab is raised.

Del has some good pics here

Removing connections from bulkhead!

-