You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your home made tools

- Thread starter fishy68

- Start date

-

Made up a CB Radio base station antenna.

9' Whip and 21" diameter Ground Plane, mounted 16' up off the ground on the front of the shop.

Next step > raise it higher yet. Higher up = more distance.

View attachment 1715963173

View attachment 1715963174

View attachment 1715963175

View attachment 1715963177

Big improvement so far, getting it tuned in.

Call this making "communication tools".

Taking things to the next level of experimenting. Now installed a professional grade Base Station antenna at the optimal height of 36'. Swapped this out from my home made antenna.

Has increased my range from 3 miles to 12 plus miles. Here is a pic of me recieving the base station signal with my '76 Truck's Cobra CB and 9' whip at the town of Dundas Minnesota 12 miles South of my base.

At the end of the day I did a radio check on channel 19 from my base. Immediately got a reply back from a guy with a base antenna like mine from the North West 14 miles away just South of the city of Apple Valley.

This guy and 4 of his other buddies are all into CBs in the South Twin City area, we exchanged info and will be looking to communicate together more in the future.

Pretty nice, that's a 25 mile diameter to be able to communicate with others.

Loud & Clear

☆☆☆☆☆

Rush4x4

Well-Known Member

My torsion bar remover.

Call this making "communication tools".

Taking things to the next level of experimenting. Now installed a professional grade Base Station antenna at the optimal height of 36'. Swapped this out from my home made antenna.

View attachment 1715973988

Has increased my range from 3 miles to 12 plus miles. Here is a pic of me recieving the base station signal with my '76 Truck's Cobra CB and 9' whip at the town of Dundas Minnesota 12 miles South of my base.

View attachment 1715973994

At the end of the day I did a radio check on channel 19 from my base. Immediately got a reply back from a guy with a base antenna like mine from the North West 14 miles away just South of the city of Apple Valley.

This guy and 4 of his other buddies are all into CBs in the South Twin City area, we exchanged info and will be looking to communicate together more in the future.

Pretty nice, that's a 25 mile diameter to be able to communicate with others.

Loud & Clear

☆☆☆☆☆

Like our old cars, I was able to pick up another exact same model and year to one of my 1976 "Hy-Gain IV" base station radios.

Working fine, always taking a chance with radios that are 46 years old and unknown history.

Looked like it had OK care, so I went for it. It all worked out fine.

One on the left, cleaned it a little. Next going to give it the final polish and detailing like the one on the right.

Good Times

diymirage

HP@idle > hondaHP@redline

Need one of these to get the rear hubs off in order to slap new rear wheel bearings on a fomoco

They run about 60 bucks

Or I can grab a 7 dollar socket and spend 10 minutes with a bench grinder

They run about 60 bucks

Or I can grab a 7 dollar socket and spend 10 minutes with a bench grinder

convx4

Well-Known Member

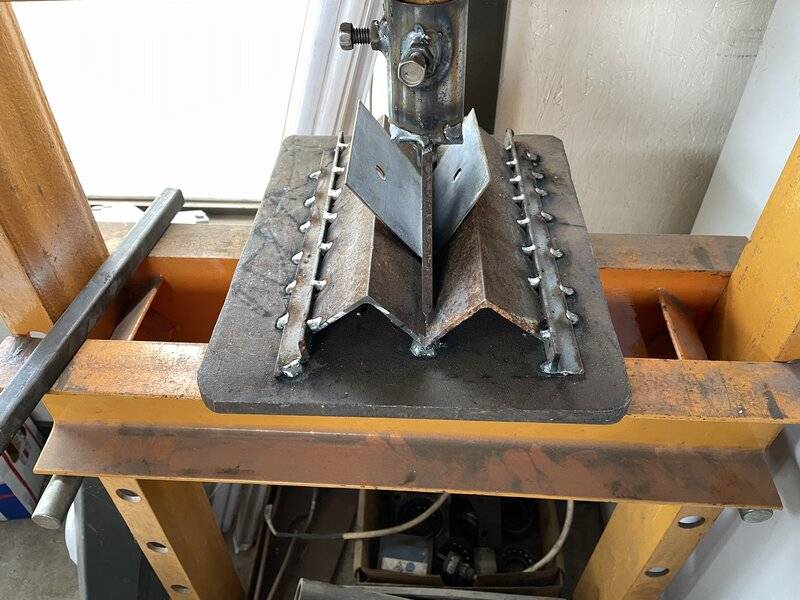

Fixture for shorting / straightening rear ends. Also working on a cutter to cut splines.

harvenator

A fish called Wanda

Someone needs a pedicure.heres an easy one for anyone to slap together,

great on the end of a breaker bar for those extra tough bolts, removing glass and windscreens, makes a great clamp in allmost any position, or even that little bit of extra thump to move something stubborn.

just remember you saw it here first

A brilliant multi purpose toolapparently, theres a beefed up version with a steelcap boot attatched too!!

harvenator

A fish called Wanda

What is it?Here's one, will post others as soon as I locate em and take pic's.

harvenator

A fish called Wanda

Do you know anyone that can straighten bumpers in preparation for coating?The big oven is 7 x 4 x 3 and 6'9" is about the longest piece I'm comfortable putting in there. It has a 3" central trolley channel in the ceiling for motorcycle frames, bumpers and stuff. Thanks for asking Idaho!

Do you know anyone that can straighten bumpers in preparation for coating?

What the bumper rechromers do is put the bumper in a press to get into the general original shape.

Then for the dents they do a process called Pick and Filing. 3/4" wide pick blade on a hammer that they use to whack the dents from the back side, then they grind the area smooth to shape on the outer side of the bumper. On the Rechrome bumpers you can see the hammer/pick marks on the back side from doing their prep work.

It's called metal finishing, a bumper rechrome shop has the skills to prep a bumper for you. Or a skilled body man may be able to help you out.

Scamp Rhonda

Well-Known Member

It's a pipe bender. I wanna see more and what size it will take.What is it?

Do you know anyone that can straighten bumpers in preparation for coating?

Maybe TriCity?

Keep in mind though that powder coating over chrome is NOT the proper way to do it, though lots of people do. I'm not one of them.

The absolute best way is to get that chrome chemically removed at a chrome shop first because it's faster and a lot cheaper than trying to blast it off, especially a good old triple plated nickel / copper / chromium job. Even trying to get a decent blast profile on it takes hours, and even then is half *** ... because any impact can take not only the powder layer off but the chrome layer as well. Then the elements get to work on it and before you know it, the whole job is coming off in sheets as rust forms in between. It's called "creep."

When that happens, it isn't the chrome shop whose reputation suffers. It's the powder guy who is rightly at fault for not doing it properly the first time by applying the powder onto a bare, impeccably clean substrate (the blasted bare steel bumper).

Put your chosen powder shop on the spot by asking exactly what prep your bumper will go through. If "I'll rough it up with a ScotchBrite pad" is part of the answer, you'll get exactly what you pay for: a half *** job.

Hopefully whomever you get to straighten them can also strip the old chrome off for you too. If you don't get it down to bare metal, you're wasting your money and tempting Fate that it's going to last.

harvenator

A fish called Wanda

Thanks so much for that info. I'm a gear head but have never gotten in to any of the body work due to time, space and equipment restraints. I learn something g new every day.Maybe TriCity?

Keep in mind though that powder coating over chrome is NOT the proper way to do it, though lots of people do. I'm not one of them.

The absolute best way is to get that chrome chemically removed at a chrome shop first because it's faster and a lot cheaper than trying to blast it off, especially a good old triple plated nickel / copper / chromium job. Even trying to get a decent blast profile on it takes hours, and even then is half *** ... because any impact can take not only the powder layer off but the chrome layer as well. Then the elements get to work on it and before you know it, the whole job is coming off in sheets as rust forms in between. It's called "creep."

When that happens, it isn't the chrome shop whose reputation suffers. It's the powder guy who is rightly at fault for not doing it properly the first time by applying the powder onto a bare, impeccably clean substrate (the blasted bare steel bumper).

Put your chosen powder shop on the spot by asking exactly what prep your bumper will go through. If "I'll rough it up with a ScotchBrite pad" is part of the answer, you'll get exactly what you pay for: a half *** job.

Hopefully whomever you get to straighten them can also strip the old chrome off for you too. If you don't get it down to bare metal, you're wasting your money and tempting Fate that it's going to last.

pishta

I know I'm right....

Something I whipped up to find a leak in my 2012 Caravan radiator (WTF, are these vans only made to last 10 years?). Bought a new one and the SOB leaks worse than the first! Have to pull it again and find the leak (low passenger side front i suspect. Plastic bullshit radiators, Ill get with the Amazon seller for a replacement. Only leaks under pressure so these plugs clamp on the upper and lower bungs and one has a Schrader valve to pressurize the rad. A few pumps with the cap on and a good ear will get you close. A squirt of soapy water will make any hole bubble. This one was split under the upper hose. I'll repair and use it for my break in rig.2x $5 1 1/2-1 1/4 tube couplers , 2 x 60 cent 1 1/2 knock out plugs and a screw in Schrader valve. Could probably use it on the vehicle too if you clamp one of the knock out caps in the removed upper rad hose and then the pressure cap on the open rad bung. pump it and watch for the leaking to start. The 13lb cap will vent before your rad balloons.

Last edited:

Scamp Rhonda

Well-Known Member

Wow! That's really homemade.

JDMopar

Well-Known Member

Tri City Plating....right there in The Volunteer State! Elizabethton, TN, near Johnson City. They are the best there is at replating bumpers!Do you know anyone that can straighten bumpers in preparation for coating?

I had and old screw driver that had a broken handle that had the correct hex welded to a piece of rod to spin the oil pump to prime the motor. I misplaced it and needed an alternative. I almost was ready to cut up my caulk gun as that would have worked, that's a good caulk gun; shame to cut it up. While at the hardware store picking up some spray paint...$6, long enough, no welding. Maybe since it's red, it will be easier to find next time I need it.

Need a few bends on heavy gauge sheet metal. Think it will work fine.

That's nice, but why just tack welds?

I dont think it needs more than tacks. I have a small piece of angle iron welded under the V to prevent it from pushing apart. Its for stuff less than 1/8”That's nice, but why just tack welds?

-

Similar threads

- Replies

- 5

- Views

- 997

- Replies

- 36

- Views

- 3K

- Replies

- 30

- Views

- 915

- Replies

- 0

- Views

- 263