I use the 1008s at up to 11.0cr/ 185psi no problems, also with Eddies, and also up to 34* timing, usually 32* occasionally 39* when I forget to crank back my dial-back timing box .

Don't tell anybody but I reused them a couple of times too; cheapest headgaskets I ever bought,lol.

I tightened them to 100ftlbs on ARP bolts, with their assembly lube, in multiple steps. Engine hasn't been apart since 2004 or 2005, and those gaskets have probably got over 80,000 miles on them........ in total,lol.

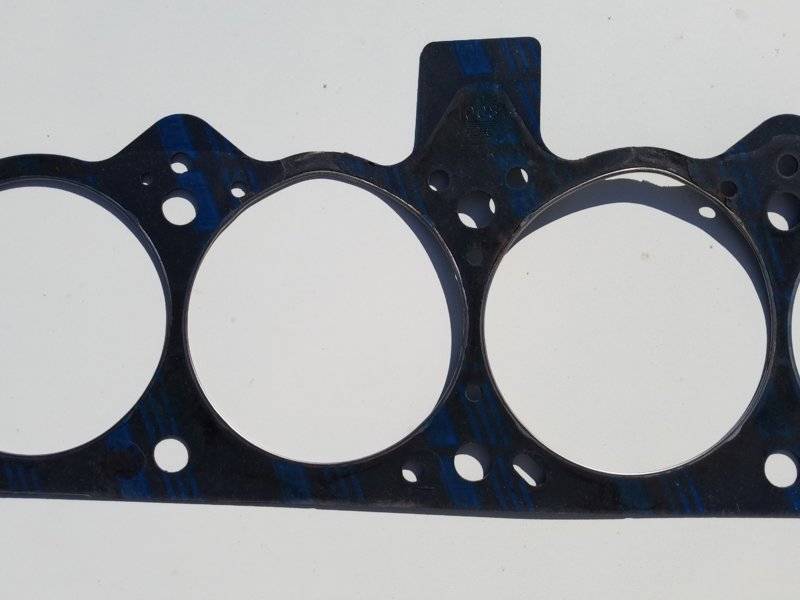

IDK why yours puked, but I'm a big fan of those FelPros. The previous non FelPro .028s did just what yours are doing, just not on as many cylinders. I caught it at seasons-end before it lost pressure.

Mine's just a 367 streeter.

EDIT; IDK if it makes a difference but I run a minimum coolant temp of 205*

I think if you flip the heads upside down, they might have a story to tell, and so might the intake gaskets