I was still truing tires for a local large family run chain well into the early 90s. Some still do.For those that want accurate information on Loctite 660, the data sheet can be found here https://www.henkel-adhesives.com/us/en/product/retaining-compounds/loctite_660.html

It's also $11.99 for a tube, so I'm not sure what the "have you seen loctite prices" thing is about. $12 is a lot less than a spray weld and machine work will cost.

https://www.amazon.com/dp/B000O03DK0/?tag=fabo03-20

Loctite 660 was literally designed to repair worn parts without remachining, specifically keyways and bearing races. So it's perfectly suited for repairing a worn hub for a bearing race. It was designed for gaps up to .02", so, that would mean the outer diameter of the race could be .04" smaller in diameter than the inside of the hub and Loctite 660 would still work. It's release temperature is 250° C, so, that's 482°F. If your bearing race hits 482°F you have a serious problem. High temp wheel bearing grease will boil around 450°F and has an ignition temp of ~500°F.

So as long as your hub/race clearance is within the specs of the Loctite 660, that's a perfectly viable repair. Spray welding and machining the hub would be a more permanent solution, but even the spray welding process doesn't create the same product as when the hub was new. It's still a repair involving different materials than the original metal. It also has a range of acceptable uses, just like the Loctite. And you can sleeve the hub too, but in that case you have two places where things can fail, at the race to the spacer and at the spacer to the hub. Done correctly it shouldn't ever be an issue, but regardless it's another place for potential issues. Bottom line is use a repair that's suited for the amount of wear you have. Even a brand new hub can spin a bearing race if it's not toleranced correctly.

Of course you could always go to 73+ disks which have the hubs integrated into the rotors, so, new hubs with every set of rotors and if you spin a race you just buy a new rotor. But that's a complete brake conversion.

Also, just some trivia for those that don't know, but truing tires was a common practice for bias ply tires. The manufacturing process of bias ply tires frequently meant they were out of round, and shaving them down to be true was something most tire shops used to be able to do. Radial tires generally don't need this and typically only racers shave their radial tires, but it's not to true them, it's to reduce weight and tread depth for better performance.

Truing bias ply tires

Truing Bias-Ply Tires - Street Rodder Magazine

Shaving tires for autoX

https://www.tirerack.com/tires/tiretech/techpage.jsp?techid=67

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

loose bearing race - K/H disc hub

- Thread starter str12-340

- Start date

-

Yes!

There are hubs out there, I would not buy an east coast hub high probability of excessive rust.

There is also the mustang hub and disk that can be modified to fit and gain 5x4.5 bbp

Here are some east coast hubs. What rust are you talking about. I sell a lot of nice parts on here and I don't import them.

Here we go again!

PUT EM UP

PUT EM UP

I was eating breakfast and my son walked in . I asked him if he had a loose race in a rotor hub how would he fix it/ And can you use Loctite. His first response was get a new one. After I told him they are not available. He said the only way to correctly fix that rotor would be sleeve it. I asked him the cost to do it? He said $100

I mention loctite? He said a definite NO .

I mentioned spray weld . He told me it would be very hard to get the torch in the small area of that size race. Also the weld would turn the hub completely cherry red. He said the best way to do it is sleeve it. Much Cheaper then getting a steel hub made and you wouldn't see the repair.

So the permanent repair would cost around $100 dollars. A replacement used hub a little more. But repairing would be double shipping.

My son can repair anything. He does a lot of work for prominent race car owners and builders. He trues the spindles on Troyer Nascar race cars and other items. If he says no loctite. Its no loctite for me.

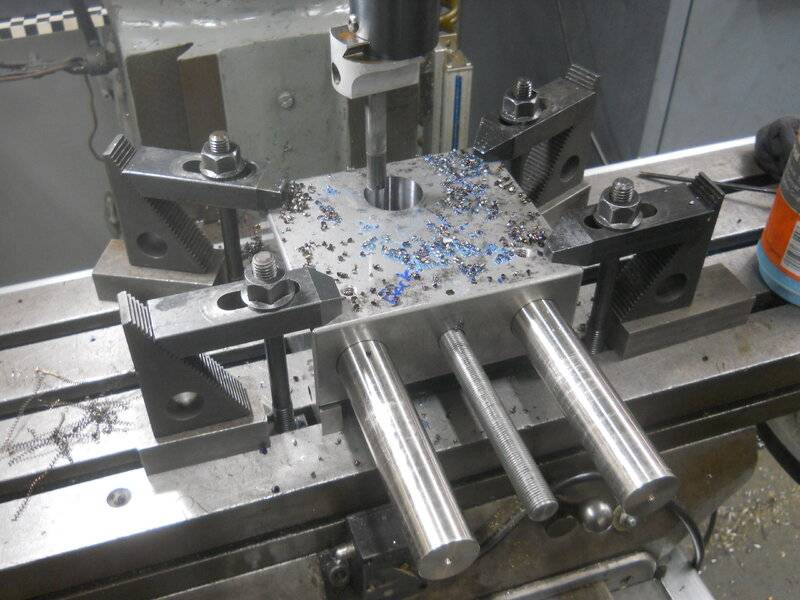

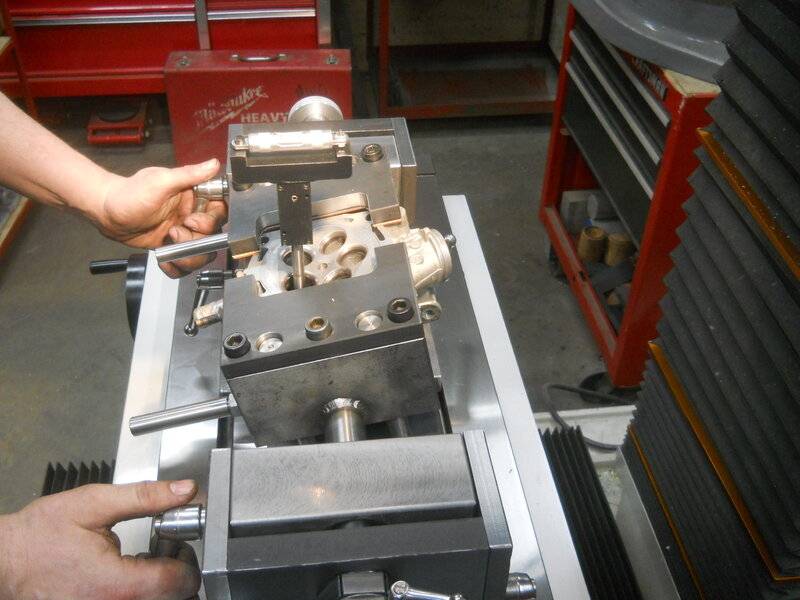

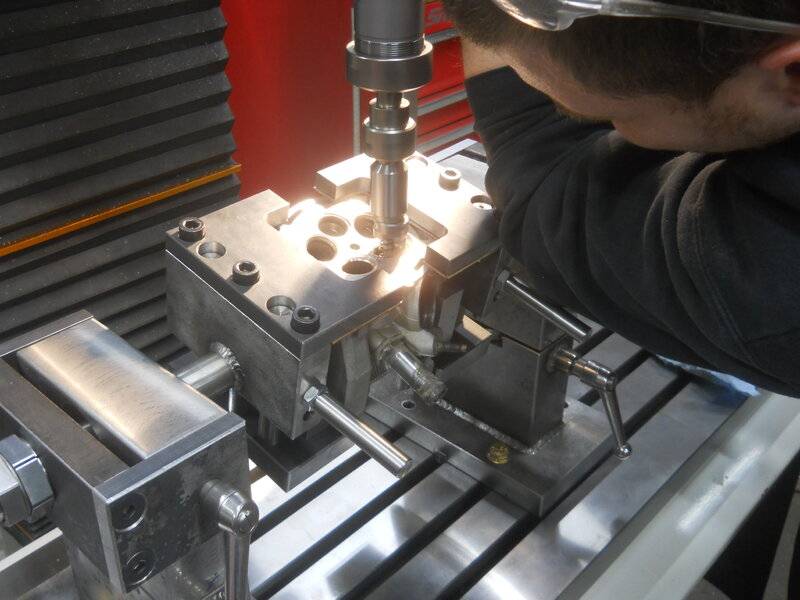

Some of the machine tooling he designs and makes is precise and unbelievable. I would have to listen to what he says'

I mention loctite? He said a definite NO .

I mentioned spray weld . He told me it would be very hard to get the torch in the small area of that size race. Also the weld would turn the hub completely cherry red. He said the best way to do it is sleeve it. Much Cheaper then getting a steel hub made and you wouldn't see the repair.

So the permanent repair would cost around $100 dollars. A replacement used hub a little more. But repairing would be double shipping.

My son can repair anything. He does a lot of work for prominent race car owners and builders. He trues the spindles on Troyer Nascar race cars and other items. If he says no loctite. Its no loctite for me.

Some of the machine tooling he designs and makes is precise and unbelievable. I would have to listen to what he says'

my68barracuda

Well-Known Member

You forgot to mention,

Your sons profit when he does the repair $100.00

Your sons profit when Loctite is used $0.00

Now have your son provide a functional engineering reason why Loctite 660 when used properly would not be an appropriate repair.

That means that he would need to look at and read and understand the physical property’s and repair specifications of the product. Those are generally listed in post # 25 that same post also has a link to the complete product specifications,mentioning that just to make it easy for your son.

Your sons profit when he does the repair $100.00

Your sons profit when Loctite is used $0.00

Now have your son provide a functional engineering reason why Loctite 660 when used properly would not be an appropriate repair.

That means that he would need to look at and read and understand the physical property’s and repair specifications of the product. Those are generally listed in post # 25 that same post also has a link to the complete product specifications,mentioning that just to make it easy for your son.

Last edited:

Jim Lusk

Well-Known Member

My only comment on this is that the problem with the bad hub may not have been a spun race. My first Dart lost a wheel bearing about a month after I bought it (mechanic who replaced them for the previous owner did not grease them...). New race on the inner was loose because the hub was cracked from the heat. I have one K-H hub here that the inner was loose going in. I never looked to see why, I just grabbed another that I had and used it. That hub is still around here somewhere...

I suspect most of us will be gone before all the hubs are gone, most of us will be lucky for another 20 to 30 years.from before they're all gone. ......and they will be all gone one day

By then the government will ban our cars from the roads and there will be no gasoline to run them on.

Those are very nice indeed.you talking about. I sell a lot of nice parts on here and I don't import them

For the record I was not specifically pointing my statement at anyone. Just a general buyer beware kind of thing when buying parts. I'm spoiled on So Cal parts!

Many of the parts I see being offered on FABO as "rust free" from the east coast, oof! I suspect there is a difference in perspective.

I'm also sure you have seen your share of rusted behind useability parts.

But we digress!

67Dart273

Well-Known Member

There is ZERO chance I would trust a 70+ mph hotrod to a center punch and a few dimples. And BELIEVE ME guys, I have done some red neck **** in my day!!

I just went out to the state line area the other day, --about a 15 mi drive and the 70mph freeway was doing more like 75 in the slow lane and 78-80 in the left lane!!!!

I just went out to the state line area the other day, --about a 15 mi drive and the 70mph freeway was doing more like 75 in the slow lane and 78-80 in the left lane!!!!

67Dart273

Well-Known Member

Loctite was NEVER made to fill gaps in machined surfaces especially under load. When you have a BEARING RACE (which is quite brittle and can fracture) and you are trying to support it with an elastic material in a cavity that is loose and likely not round, you are "engineering yourself" into an outer space of unknowns. WHAT HAPPENS if that race breaks, or cracks, and it screws up a needle in that bearing? What happens at 70+? 90+? What happens on a highway in the middle of the AZ desert? Or even "up here" on a hot summer day?You forgot to mention,

Your sons profit when he does the repair $100.00

Your sons profit when Loctite is used $0.00

Now have your son provide a functional engineering reason why Loctite 660 when used properly would not be an appropriate repair.

That means that he would need to look at and read and understand the physical property’s and repair specifications of the product. Those are generally listed in post # 25 that same post also has a link to the complete product specifications,mentioning that just to make it easy for your son.

My only comment on this is that the problem with the bad hub may not have been a spun race. My first Dart lost a wheel bearing about a month after I bought it (mechanic who replaced them for the previous owner did not grease them...). New race on the inner was loose because the hub was cracked from the heat. I have one K-H hub here that the inner was loose going in. I never looked to see why, I just grabbed another that I had and used it. That hub is still around here somewhere...

A very valid point. But that goes back to making sure that you inspect the hub and determine what repairs are appropriate.

It's a 50+ year old part, so it's best not to assume what the problem is and do a thorough inspection. Just because one method of repair might be "better" doesn't mean it will work best in a particular case.

Loctite was NEVER made to fill gaps in machined surfaces especially under load. When you have a BEARING RACE (which is quite brittle and can fracture) and you are trying to support it with an elastic material in a cavity that is loose and likely not round, you are "engineering yourself" into an outer space of unknowns. WHAT HAPPENS if that race breaks, or cracks, and it screws up a needle in that bearing? What happens at 70+? 90+? What happens on a highway in the middle of the AZ desert? Or even "up here" on a hot summer day?

Clearly you didn't bother to look up Loctite 660 or follow the link I posted to its data sheets. It was literally designed to fill gaps for bearing races, that's the reason it exists. This is not blue or red Loctite thread locker.

Hell even in the scenario where the hub gets a sleeve there are plenty of machinists out there that would use a locking compound on the sleeve to hub interface, there are compounds out there for various different classes of fit.

Last edited:

cudamark

Well-Known Member

Al kinds of suggestions as to how to "fix" it. Since a good used one is available, make your life simple and just go that way. With a repair, who knows how well it will hold up, or what you would need to do with a future bearing replacement. Would you have to go through with another "fix" at that point? Not worth it IMO since you can just get another part. I'd also take a good look at your spindle. If the bearing got hot enough to spin the race (and maybe the cone), it may have damaged the spindle also.I'm working on rebuilding a set of original K/H disc brakes on my 1970 Dart. In replacing the wheel bearings I found that one of the outer bearing races was loose in the hub - I could take my fingers and move it around in the hub. I got a new bearing and race and installed that race and had the same results. It is tight as I drive the race in, but when it gets into place it is loose - I can turn it and can wiggle it up and down a little bit. Is this hub toast? Is there a way to fix this hub?

Rat Bastid

Dunamis Metron

Al kinds of suggestions as to how to "fix" it. Since a good used one is available, make your life simple and just go that way. With a repair, who knows how well it will hold up, or what you would need to do with a future bearing replacement. Would you have to go through with another "fix" at that point? Not worth it IMO since you can just get another part. I'd also take a good look at your spindle. If the bearing got hot enough to spin the race (and maybe the cone), it may have damaged the spindle also.

100% fact. I never set a sleeve like that without locktite. They make a special compound just for that. I keep it on the shelf for exactly that purpose.

No way would I set a sleeve like that dry.

One issue I see in this thread is we have people playing machinist when they are not.

If you loctite a race in place, I pity the the next guy trying to replace it.

my68barracuda

Well-Known Member

One would simply heat the race with a propane torch to approximately 450 F the Loctite would begin to release and the race could be knocked out like normal.If you loctite a race in place, I pity the the next guy trying to replace it.

Obviously a person that knows nothing about Loctite.

my68barracuda

Well-Known Member

Dude, there are links posted that go to the product page for Loctite 660.Loctite was NEVER made to fill gaps in machined surfaces especially under load. When you have a BEARING RACE (which is quite brittle and can fracture) and you are trying to support it with an elastic material in a cavity that is loose and likely not round, you are "engineering yourself" into an outer space of unknowns. WHAT HAPPENS if that race breaks, or cracks, and it screws up a needle in that bearing? What happens at 70+? 90+? What happens on a highway in the middle of the AZ desert? Or even "up here" on a hot summer day?

In about the same time it took you to post wrong information you could have educated yourself.

Think about that the next time you are driving a car, that you worked on at highway speeds.

Last edited:

Al kinds of suggestions as to how to "fix" it. Since a good used one is available, make your life simple and just go that way. With a repair, who knows how well it will hold up, or what you would need to do with a future bearing replacement. Would you have to go through with another "fix" at that point? Not worth it IMO since you can just get another part. I'd also take a good look at your spindle. If the bearing got hot enough to spin the race (and maybe the cone), it may have damaged the spindle also.

The only issue here is what is a "good" used one. No matter what you're buying a used hub. Maybe you're buying one that's perfect, but more than likely you're buying one that has some kind of wear somewhere. And most of the time when you're buying a hub you probably don't have the opportunity to measure all the tolerances beforehand. So it would be pretty easy to just trade one problem for another, or get another hub that has a race issue.

Don't get me wrong, I'm not saying I wouldn't try to find a replacement. But they're not making any new ones, and until they do it's going to become more and more necessary to repair them with one method or another.

If you loctite a race in place, I pity the the next guy trying to replace it.

Like stated, you just heat it and the race will fall out. Granted, at that point the next guy will have to decide how to repair the hub again, but, that can happen regardless.

These things do have a life span, even hubs that are assembled without any issues will eventually need some repair work or replacement.

100% fact. I never set a sleeve like that without locktite. They make a special compound just for that. I keep it on the shelf for exactly that purpose.

No way would I set a sleeve like that dry.

One issue I see in this thread is we have people playing machinist when they are not.

Exactly.

67Dart273

Well-Known Member

No this is NOT wrong information. There is no possible way that loctite can fix a LOOSE bearing, one that is loose enough to "feel" loose. The load on that bearing is TREMENDOUS. Every bump you hit is a severe impact on that race. It MUST have a machined precision land to rest against and to support it and keep it "round". The bearing race is not strong within itself. It was never designed to "bridge" a load.Dude, there are links posted that go to the product page for Loctite 660.

In about the same time it took you to post wrong information you could have educated yourself.

Think about that the next time you are driving a car, that you worked on at highway speeds.

This is like fixing a sagging roof with cardboard boxes, I do not care what loctite claims

cudamark

Well-Known Member

Typically, there is no wear on a hub. That's what the bearing races are for. As long as you don't spin a race, the hub is pretty bulletproof. Naturally, you have to know what you're doing when replacing a rotor, or, you could damage the hub that way too, but, other than that, just what is going to hurt a hub?

No this is NOT wrong information. There is no possible way that loctite can fix a LOOSE bearing, one that is loose enough to "feel" loose. The load on that bearing is TREMENDOUS. Every bump you hit is a severe impact on that race. It MUST have a machined precision land to rest against and to support it and keep it "round". The bearing race is not strong within itself. It was never designed to "bridge" a load.

This is like fixing a sagging roof with cardboard boxes, I do not care what loctite claims

Loctite, as a company, wouldn't make that claim if they couldn't support it. They'd get sued like crazy every time there was a failure. From an engineering standpoint I would bet the published capabilities are well under what that material is actually capable of doing, just for legal reasons.

As for what feels loose, that's completely subjective isn't it? No one has said to use loctite no matter what, the hub has to be measured so it can be determined if the Loctite 660 is a viable repair. It may not be in this particular case, but that doesn't mean it's not a useful product or that other people may not be able to use it successfully.

Typically, there is no wear on a hub. That's what the bearing races are for. As long as you don't spin a race, the hub is pretty bulletproof. Naturally, you have to know what you're doing when replacing a rotor, or, you could damage the hub that way too, but, other than that, just what is going to hurt a hub?

You think the "interference fit" doesn't cause some wear to the hub when you replace the races? What about the studs? The forces they apply to the hub will eventually wear those holes. Certainly removing and replacing studs is something you can only do some many times before you need oversized studs to achieve the proper fit.

My point is that while serviceable, the hubs do have a lifespan even when everything is done properly. And all it takes is one race to get a little crooked when it's being installed to cause tolerance issues later. If everything is done perfectly you can replace a whole lot of races before the hub will fall out of tolerance, but not everything is always done perfectly. And over 50+ years, **** happens.

my68barracuda

Well-Known Member

The Loctite product has test results performed to industry wide standardsNo this is NOT wrong information. There is no possible way that loctite can fix a LOOSE bearing, one that is loose enough to "feel" loose. The load on that bearing is TREMENDOUS. Every bump you hit is a severe impact on that race. It MUST have a machined precision land to rest against and to support it and keep it "round". The bearing race is not strong within itself. It was never designed to "bridge" a load.

This is like fixing a sagging roof with cardboard boxes, I do not care what loctite claims

That indicate the product will perform satisfactory in the environments listed when used as directed.

Please publish your test results, also performed to some industry standard that supports your position that it will not.

And again, it is ok for you to think about this while driving a car that you worked on at highway speeds.

I don't really give a flyin **** about the argument, but here is the Locktite 660 product description page if anyone cares to read it. It does see to support that it can be used for this type repair. I'm not arguing one way or the other, so don't attack the messenger.

https://docs.rs-online.com/66cf/0900766b8106d18f.pdf

https://docs.rs-online.com/66cf/0900766b8106d18f.pdf

Which was available on the link I posted way back at post #25, and pops up right away if you even bother to google the stuff.

The folks arguing against Loctite 660 still won’t read or understand it.

The folks arguing against Loctite 660 still won’t read or understand it.

Loctite, as a company, wouldn't make that claim if they couldn't support it. They'd get sued like crazy every time there was a failure. From an engineering standpoint I would bet the published capabilities are well under what that material is actually capable of doing, just for legal reasons.

As for what feels loose, that's completely subjective isn't it? No one has said to use loctite no matter what, the hub has to be measured so it can be determined if the Loctite 660 is a viable repair. It may not be in this particular case, but that doesn't mean it's not a useful product or that other people may not be able to use it successfully.

You think the "interference fit" doesn't cause some wear to the hub when you replace the races? What about the studs? The forces they apply to the hub will eventually wear those holes. Certainly removing and replacing studs is something you can only do some many times before you need oversized studs to achieve the proper fit.

My point is that while serviceable, the hubs do have a lifespan even when everything is done properly. And all it takes is one race to get a little crooked when it's being installed to cause tolerance issues later. If everything is done perfectly you can replace a whole lot of races before the hub will fall out of tolerance, but not everything is always done perfectly. And over 50+ years, **** happens.

Wow you can really come up with some incredible. stories. Hubs and studs have a life span and all wear out??? Where the **** did you get that story from. Some of these cars are 60 years old and the hubs are like new with 2-3 K miles on them.

You think my hub I offered is no good. Well you sell him one asshole.

Everytime there is a suspension question you come on here like a god and write a book of reply's . I never seen one time where you actually offered anyone any physical help with parts. Only your big inconsistent stories. So you can tell this member a story to solve his problem.

I have nothing more to say and nothing to offer to help. You ruin this mans help from me with your big mouth and stories. I will not reply to sell any hubs yo anyone. I'll sell them at the shop in person.

As far as loctite read their disclaimer.. Now Go sell your pipes and bongs at your Cannabis store .

my68barracuda

Well-Known Member

Wow you can really come up with some incredible. stories. Hubs and studs have a life span and all wear out??? Where the **** did you get that story from. Some of these cars are 60 years old and the hubs are like new with 2-3 K miles on them.

You think my hub I offered is no good. Well you sell him one asshole.

Everytime there is a suspension question you come on here like a god and write a book of reply's . I never seen one time where you actually offered anyone any physical help with parts. Only your big inconsistent stories. So you can tell this member a story to solve his problem.

I have nothing more to say and nothing to offer to help. You ruin this mans help from me with your big mouth and stories. I will not reply to sell any hubs yo anyone. I'll sell them at the shop in person.

As far as loctite read their disclaimer.. Now Go sell your pipes and bongs at your Cannabis store .

Hey Old Man, where is your son’s functional engineering assessment of the Loctite 660 ?

You seem very interested in selling parts and services that put money in your pocket and much less interested in solutions that do not. Maybe you should add that as the disclaimer to your posts.

Last edited:

-