Thanks RRR... a note to add. In that video, that is our Canadian Paralympics volleyball team she is playing with at the end of the video. Jennifer was the Recreation Administrator for Ryerson University. She got to sit in her new office chair once in the new Mattamy building (Maple Leaf Gardens) before getting too ill to go back to work anymore.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 Dodge Dart Swinger clean up

- Thread starter dadsbee

- Start date

-

Mineallmine

Well-Known Member

Sorry to hear about your loss. I lost a son to e-wing sarcoma 4 years ago. He was only 19. It was less than a year from the diagnosis until he passed. My project to keep me sane was I had started building a new garage. After he passed I worked non stop until it was finished. He loved the old cars as well. He always talked about a 60 Chev Bel Air 4 door I used to own. I since bought a 60 Bel Air 2 door sport coupe to fix up in his memory. The dart was to get me back at the old cars. The Bel Air will have a tribute incorporated in it.My "scenario" was almost 6 years sitting in the corner of our Daughters hospital room, found myself a lot of patience I didn't know I had. Losing her started my 4.5 year Bee restoration on the car known as Therapy. This Dart is just fun...

View attachment 1715665931

Car is coming along great by the way. Can't wait to see the finished product. You're attention to detail is inspiring.

Sorry to hear that, it's a miserable f'n disease with about a 5% survival rate no matter how they spin it to you. I hate saying it, but our Children getting run down by a bus would have been more humane for both them and us parents.

Steering gear (Pitman) arm slipped in place.

Lock washer and thin nut. 1 1/4" socket.

Wheaties for breakfast... nut tightened to 175 foot lbs.

Idler arm going on and despite what you normally see this is correct to have the bolt upside down. Tightened to 65 ft-lbs.

Center/drag link in place. Note correct orientation. Longer attachment "flat" is the drivers side. Tie rod studs tapered sockets go big diameter forward.

Aftermarket nuts, that leave you thinking you should have a washer to go with them, with the cotter hole above the nut. Why can't they just supply correct hardware?

An aircraft AN310-8 nut, original Chrysler OE 3 castle nut and the aftermarket nut showing it's short comings.

Swapped out the cheap tin cotter pins for some nice cad MIL spec ones.

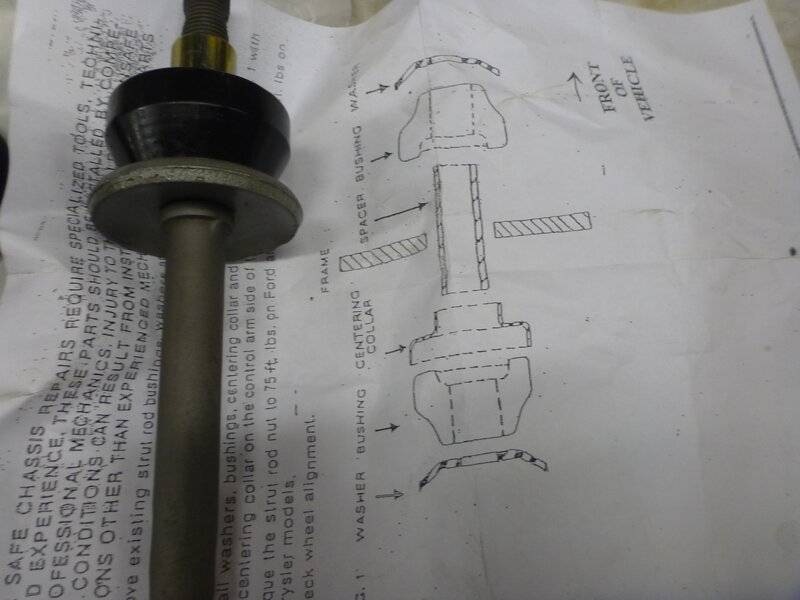

This round I'll follow PST's install diagram, with the inner strut washer installed backwards.

In case you're searching for the correct nuts, this is the strut rod nut that holds it to the LCA.

Lock washer and thin nut. 1 1/4" socket.

Wheaties for breakfast... nut tightened to 175 foot lbs.

Idler arm going on and despite what you normally see this is correct to have the bolt upside down. Tightened to 65 ft-lbs.

Center/drag link in place. Note correct orientation. Longer attachment "flat" is the drivers side. Tie rod studs tapered sockets go big diameter forward.

Aftermarket nuts, that leave you thinking you should have a washer to go with them, with the cotter hole above the nut. Why can't they just supply correct hardware?

An aircraft AN310-8 nut, original Chrysler OE 3 castle nut and the aftermarket nut showing it's short comings.

Swapped out the cheap tin cotter pins for some nice cad MIL spec ones.

This round I'll follow PST's install diagram, with the inner strut washer installed backwards.

In case you're searching for the correct nuts, this is the strut rod nut that holds it to the LCA.

Last edited:

Strut to LCA nut tightened to 100 ft-lbs.

Both LCA's in place c/w struts, strut bushings, washer and nut. With PST's polygraphite bushings and the metal sleeve in place you can not tighten the nut enough to use, let alone see, the spring pin hole. NOTE: DO NOT tighten the LCA shaft nut, just snug it up lightly so the shaft can still be turned using the torsion bar adjuster ear. Nut gets tightened when car is on it's wheels with ride height set.

Lower ball joints on, nut tightened at 100 ft-lbs.

LCA bump stops going into place

Tie rods and sleeves assembled. Parts manual indicates that the left hand threads are the inners, but many install one side that way and the other with a right hand thread inner so when turning the sleeves both change length in the same direction of rotation.

Old ones have apparently lived a hard life, this one is bent.

The other side the joiner sleeve is twisted.

I measure grease zerk to grease zerk to get a length for the new assembly so it's close enough to drive for an alignment.

Just need the steering knuckles and hub assemblies back on to complete the front end.

Both LCA's in place c/w struts, strut bushings, washer and nut. With PST's polygraphite bushings and the metal sleeve in place you can not tighten the nut enough to use, let alone see, the spring pin hole. NOTE: DO NOT tighten the LCA shaft nut, just snug it up lightly so the shaft can still be turned using the torsion bar adjuster ear. Nut gets tightened when car is on it's wheels with ride height set.

Lower ball joints on, nut tightened at 100 ft-lbs.

LCA bump stops going into place

Tie rods and sleeves assembled. Parts manual indicates that the left hand threads are the inners, but many install one side that way and the other with a right hand thread inner so when turning the sleeves both change length in the same direction of rotation.

Old ones have apparently lived a hard life, this one is bent.

The other side the joiner sleeve is twisted.

I measure grease zerk to grease zerk to get a length for the new assembly so it's close enough to drive for an alignment.

Just need the steering knuckles and hub assemblies back on to complete the front end.

Last edited:

Mineallmine

Well-Known Member

Not that's what I call attention to detail. Looks amazingStrut to LCA nut tightened to 100 ft-lbs.

View attachment 1715668301

Both LCA's in place c/w struts, strut bushings, washer and nut. With PST's polygraphite bushings and the metal sleeve in place you can not tighten the nut enough to use, let alone see, the spring pin hole. NOTE: DO NOT tighten the LCA shaft nut, just snug it up lightly so the shaft can still be turned using the torsion bar adjuster ear. Nut gets tightened when car is on it's wheels with ride height set.

View attachment 1715668302

Lower ball joints on, nut tightened at 100 ft-lbs.

View attachment 1715668303

LCA bump stops going into place

View attachment 1715668304

Tie rods and sleeves assembled. Parts manual indicates that the left hand threads are the inners, but many install one side that way and the other with a right hand thread inner so when turning the sleeves both change length in the same direction of rotation.

View attachment 1715668305

Old ones have apparently lived a hard life, this one is bent.

View attachment 1715668306

The other side the joiner sleeve is twisted. View attachment 1715668307

I measure grease zerk to grease zerk to get a length for the new assembly so it's close enough to drive for an alignment.

View attachment 1715668308

Just need the steering knuckles and hub assemblies back on to complete the front end.

View attachment 1715668309

Joe Mc

No Car Like A MoPar!

dadsbee, no s_ _t here, totally serious - when I grow up (I hope not anytime soon BTW) I want to be just like you, you are my hero! Awesome ADD / Anal-ism brother.

Side note: my wife used to say "Joe, will you ever grow up?" Of course my reply was "good God I hope not". Then I'd get that "look of love"...you all know the one I'm referring to LOL

Side note: my wife used to say "Joe, will you ever grow up?" Of course my reply was "good God I hope not". Then I'd get that "look of love"...you all know the one I'm referring to LOL

R4Sedan

Larry

Wayne, the car is looking great. Super detail.

jcmeyer5

Token Ford Guy

Seized? It looks like it was welder on the right end!

I think it's just grunge.. but I'll have a look at it when I hit the shop for the afternoon shift! Why I keep saying a "restoration" is not just a shinny paint job....Seized? It looks like it was welder on the right end!

FBBO forum buddy @BeatersRus , down in NY state, sent me a converter cover. Still refuses to give me an email address so I can pay him! Come'on Rob... give it to me! lol

It's even the correct cover!! 727 trans on a 340 vs the usual small block 904 transmission.

Cleaned up and about as mint as they get when they're 52 years old. Not a single bend or dent...

Why you always should use a torque wrench on critical parts! Nuts that were holding the knuckle to lower ball joint not quite up to the task! Stripped out at 65 ft-lbs.. vs what should be a 100 ft-lb process.

Fortunately I have a small supply of fine thread AN hardware..

Just a small supply....

Swapped out all Wilwood nuts. The cheap offshore 1/2" nut, that stripped, for some AN315's and the little thin 7/16ths nuts (that should only be used as a shear nut) for some real tension/lock AN365-7 nuts.

Steering knuckle going onto the lower ball joint.

Entire front end / K frame assembly together (other than sway bar) and ready for the engine/transmission to be put back into place... after I get them ready that is. NOTE: do not leave your hub assemblies just hanging and jamming/cracking the ball joint's rubber seal.

Notes...notes .. notes..

It's even the correct cover!! 727 trans on a 340 vs the usual small block 904 transmission.

Cleaned up and about as mint as they get when they're 52 years old. Not a single bend or dent...

Why you always should use a torque wrench on critical parts! Nuts that were holding the knuckle to lower ball joint not quite up to the task! Stripped out at 65 ft-lbs.. vs what should be a 100 ft-lb process.

Fortunately I have a small supply of fine thread AN hardware..

Just a small supply....

Swapped out all Wilwood nuts. The cheap offshore 1/2" nut, that stripped, for some AN315's and the little thin 7/16ths nuts (that should only be used as a shear nut) for some real tension/lock AN365-7 nuts.

Steering knuckle going onto the lower ball joint.

Entire front end / K frame assembly together (other than sway bar) and ready for the engine/transmission to be put back into place... after I get them ready that is. NOTE: do not leave your hub assemblies just hanging and jamming/cracking the ball joint's rubber seal.

Notes...notes .. notes..

4spdragtop

Well-Known Member

Documentation and work is excellent!

Only got a couple of hours in the shop today... but forward progress is forward progress!

Mail ain't moving fast, but I got my first set of used axle bump stops today, after 34 days via "priority" USPS mail. Thanks @barracudakid for getting them out immediately and even threw in the bolts!

Old undercoating darn near matches... ;O)

Mounting brackets aren't the same as the removed ones though, but the mounting hole C/C distance is correct. Gonna wait for the next pair to get here and possibly mix and match.

This fuggly air mover needs to go ! I have a factory 7 blade from a 383 HP in my parts spares that will look better and probably move more air.

Engine mounts off for clean up. Anyone know if Chrysler cut and welded the drivers side's to make them fit 340's back in '69.. as the 340 mount is unique amongst the small blocks.

Pulling off parts so they can be painted semi-gloss Black, while the bare engine can be painted Turquoise.

Removing the alternator bracket, one bolt at a time so I don't lose the water pump to block seal.

Temporary bolts in place for paint.

Transmission lines off, spark plugs out, fan off, pulleys, brackets, radiator hoses. Tomorrow the carb comes off and I'll start prepping the engine for paint. Good thing "work" is only 20 feet from the back door and essential !

Mail ain't moving fast, but I got my first set of used axle bump stops today, after 34 days via "priority" USPS mail. Thanks @barracudakid for getting them out immediately and even threw in the bolts!

Old undercoating darn near matches... ;O)

Mounting brackets aren't the same as the removed ones though, but the mounting hole C/C distance is correct. Gonna wait for the next pair to get here and possibly mix and match.

This fuggly air mover needs to go ! I have a factory 7 blade from a 383 HP in my parts spares that will look better and probably move more air.

Engine mounts off for clean up. Anyone know if Chrysler cut and welded the drivers side's to make them fit 340's back in '69.. as the 340 mount is unique amongst the small blocks.

Pulling off parts so they can be painted semi-gloss Black, while the bare engine can be painted Turquoise.

Removing the alternator bracket, one bolt at a time so I don't lose the water pump to block seal.

Temporary bolts in place for paint.

Transmission lines off, spark plugs out, fan off, pulleys, brackets, radiator hoses. Tomorrow the carb comes off and I'll start prepping the engine for paint. Good thing "work" is only 20 feet from the back door and essential !

Last edited:

In 2005 I went self employed. Where I lived & worked, the shop was 18 steps from the back door. We moved about a year later and the new shop was 14 steps from the new back door. When asked why I moved, I jokingly replied, "to get closer to work".

LOL Steve.. this car was too short for them folks!

jcmeyer5

Token Ford Guy

No, there are no welds on a stock motor mount on the 340. Looks like someone chopped it because they didn’t know how it fit.

Just weird with it being the #'s engine still in this car, but who knows what happened in the past 52 years! Mount installed..No, there are no welds on a stock motor mount on the 340. Looks like someone chopped it because they didn’t know how it fit.

jcmeyer5

Token Ford Guy

Probably cracked at some point.

Joe Mc

No Car Like A MoPar!

Most plausible reasonProbably cracked at some point.

jcmeyer5

Token Ford Guy

Actually, looking at it again, it appears that they narrowed the bracket to fit between the ears, where I think mine goes behind the ears. You can see the machined portions on both ears, and they are towards the rear

4spdragtop

Well-Known Member

It has a narrower "stance" done that way too. 318 mount mod with spacer would be better.

318 mount converted to 340/360 the hard way .

Being narrower = less to bend.. LOL.. it is in tension not compression. I'll be putting a limiter on it anyhow, just baffles me why it's there with the #'s engine in the car. BUT who knows what's been in and out of there in the 52 years previous while the OE sat on a stand or the mount was lost during an engine rebuild... is what it is, it's going back in.

Time to pull the carburetor with the least amount of disconnecting.

Brand new 4777-7 Holley. 650 double pumper.

Looks like the easiest thing to remove to get the carb set up off in one piece. Just one bracket..

..and one ball joint and no adjustments needed when it goes back together.

4 carb bolts out and the entire assembly is in a box.

Haven't seen an intake that clean other than taking one out of a box. Explains the fresh paint on the top of the engine.

Another collection of parts to detail, paint and reinstall. The fan just has to go!

Cam looks good, two lobes of it at least..

Always save your pill bottles!

Nice to see it has fresh brass frost plugs.

Brand new 4777-7 Holley. 650 double pumper.

Looks like the easiest thing to remove to get the carb set up off in one piece. Just one bracket..

..and one ball joint and no adjustments needed when it goes back together.

4 carb bolts out and the entire assembly is in a box.

Haven't seen an intake that clean other than taking one out of a box. Explains the fresh paint on the top of the engine.

Another collection of parts to detail, paint and reinstall. The fan just has to go!

Cam looks good, two lobes of it at least..

Always save your pill bottles!

Nice to see it has fresh brass frost plugs.

Last edited:

-

Similar threads

- Replies

- 19

- Views

- 413

- Replies

- 81

- Views

- 3K

- Replies

- 146

- Views

- 11K