Hemiorangeswinger

Dodge Material

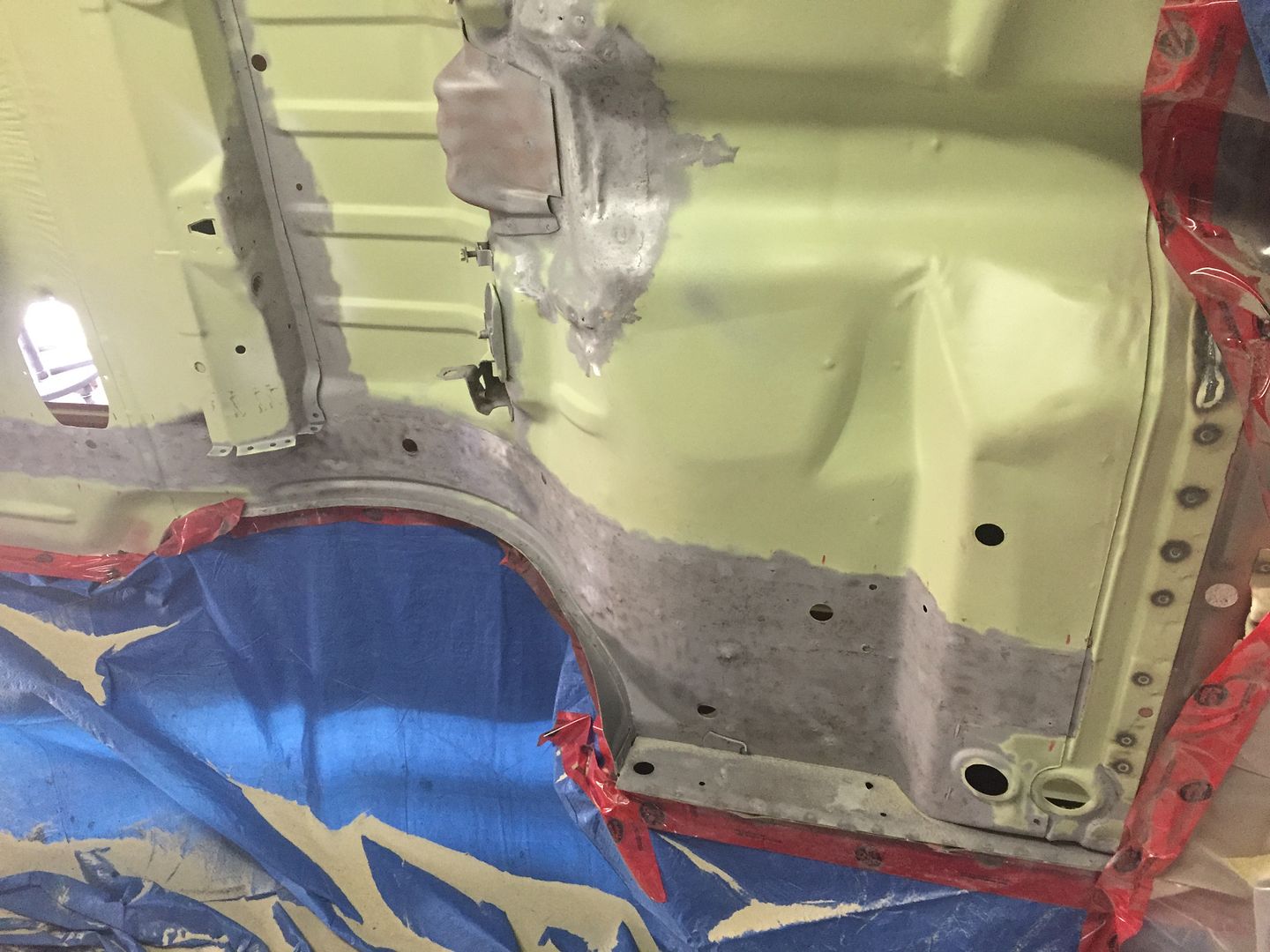

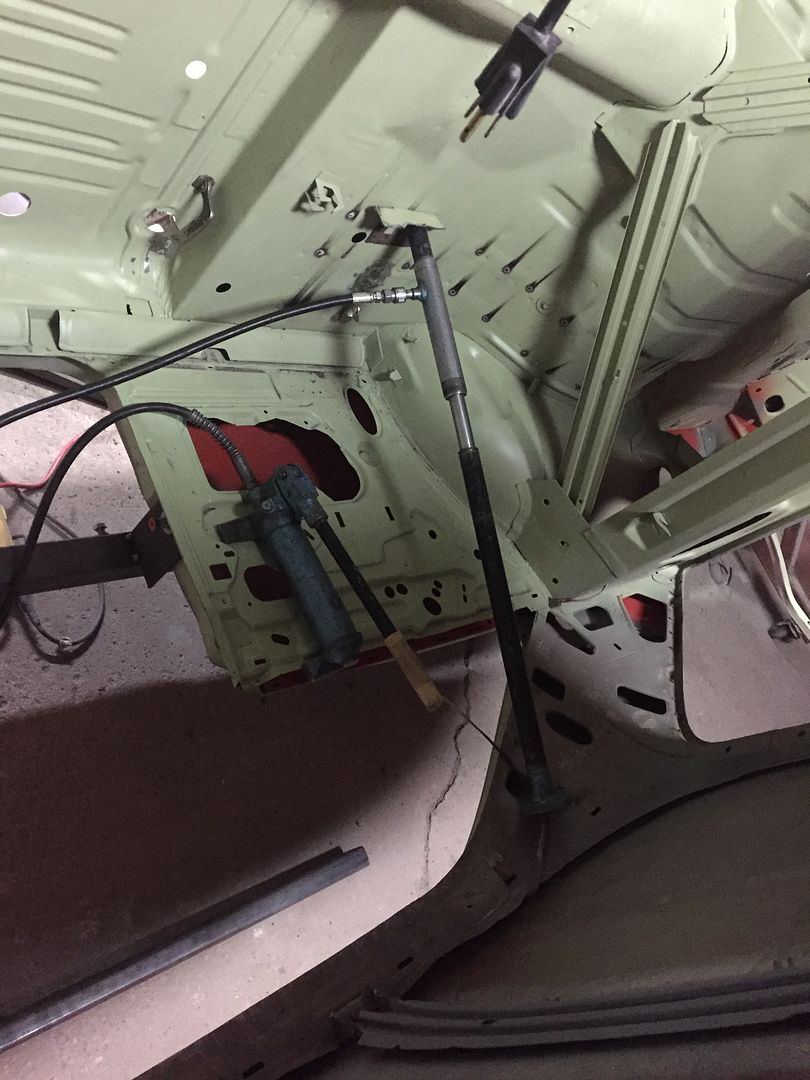

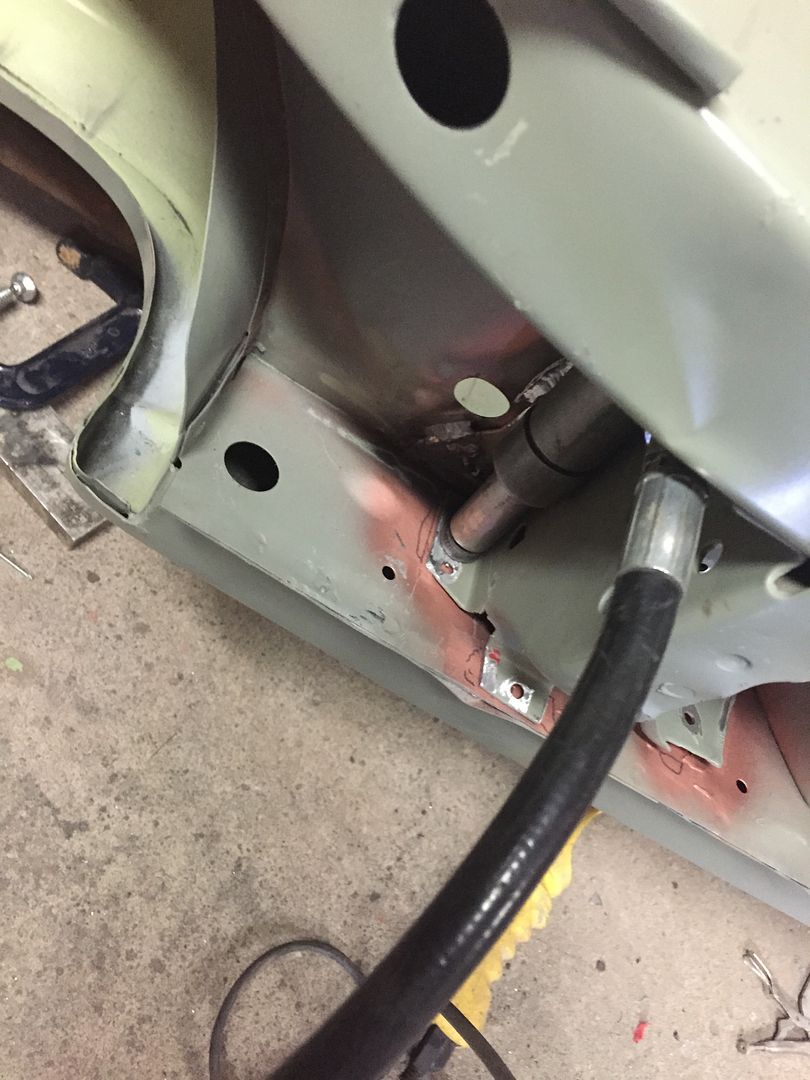

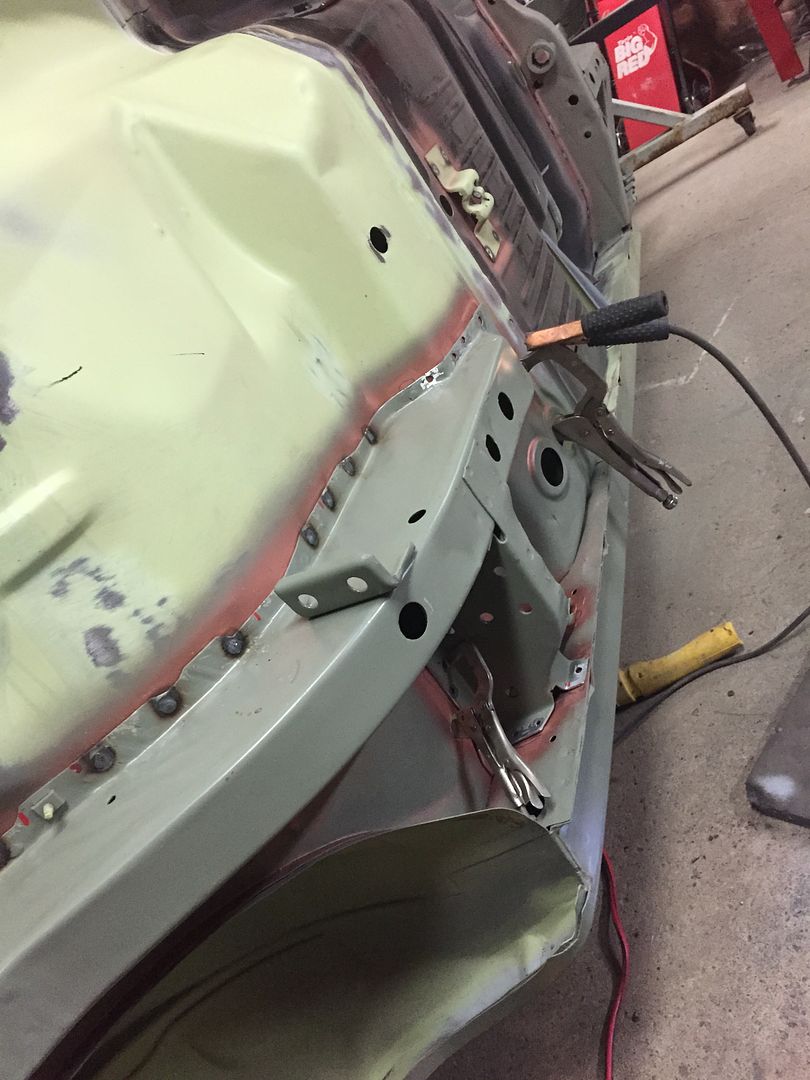

I should be around next weekend Randy, I think you have my cell no. now so feel free to call or text me. I took another look at the primer underneath Randy and the area at the back that was grey turns out to be over spray primer from when they did the spot repair at the back. I need to clean some areas that where disturbed the least like above the gas tank but I'm now leaning toward a very dark grey or maybe black primer, what I'm seeing is pretty dark. Needs some more investigation with some bright light under there. Danny

Ok sounds good, I'll send you a text later this week so we can set a time up. I am thinking my car was black underneath.. I just searched thru my old pics when I was taking the car apart and I took a pic under the gas tank and it looks black to me.. With orange overspray. I still have yet to find any grey under the car.