txstang84

Well-Known Member

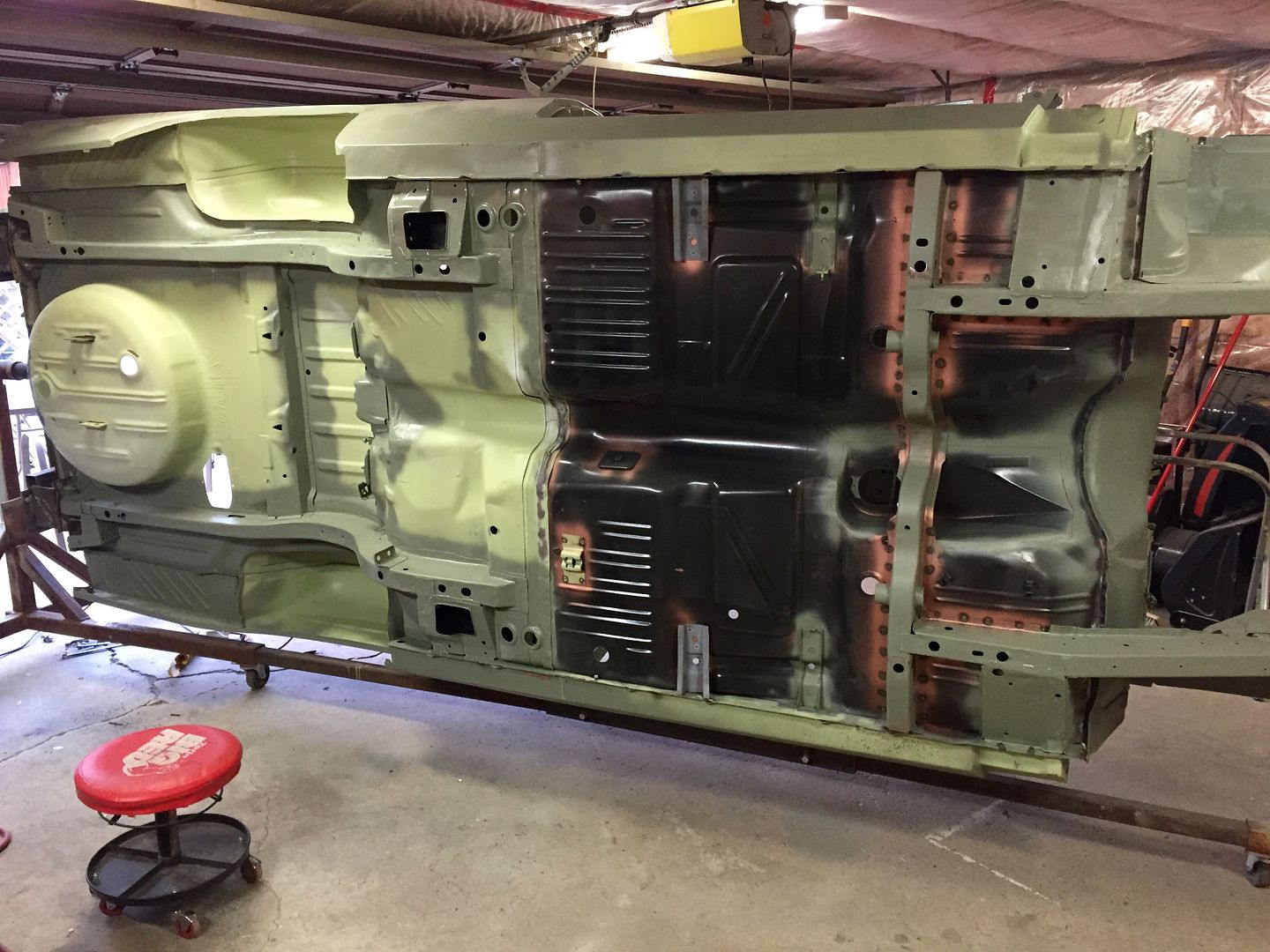

I forgot you mentioned the x member...the light at the end of this tunnel is steadily getting brighter!!

I forgot you mentioned the x member...the light at the end of this tunnel is steadily getting brighter!!

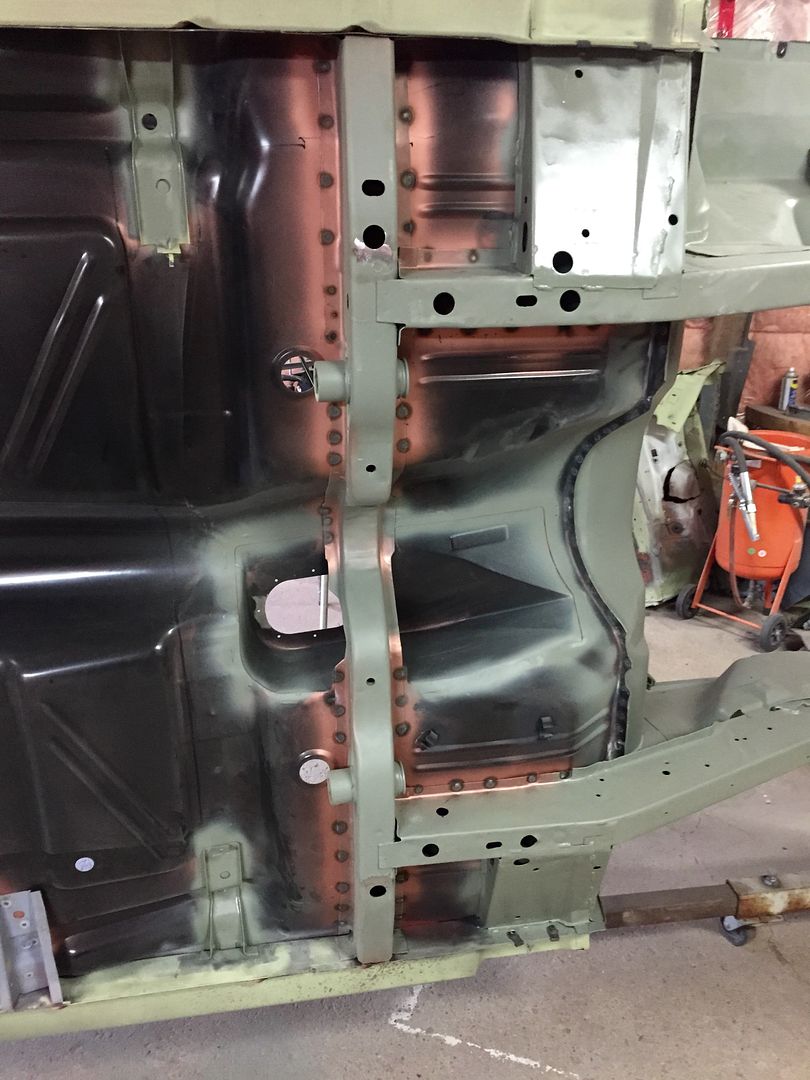

Excellent work on those frame rails.

Man you have been doing a hell of job and like someone already said I have to admire your patience and persistence. It has taken me 3 days just to read this from the beginning!!!! And it really is a 3 year odysee espeacially for you. But thank you so much for the extra time it has no doubt taken you to post all your steps. I just got done with my 69 340 swingers body and paint but thankfully I live in Az. and brought my Dart here from Maryland,only one or two small rust spots, but thanks again it has been an educational thread, best of luck to you. Paul

Randy I will look on my old computer, but I have been through a few phones and still havnt figured out how to get them from the camera to the computer!! Just not that computer savy I guess. But yes my car was driven out to Az, by me in 1981 so yes it is almost like new underneath, we only fixed 1 rust spot over right rear wheel, which we cut out and replaced the metal, and after the car came home and I began to put carpet kit in found the passenger floor board rusted a little worse tan I wanted, so back on the flatbed bought a very high quality pass. floorpan and replaced that also. Then back home again. I think bad heater core caused it because car was always on concrete and under cover. Took tank out last weekend derusted the inside of that car runs so much better than it did. Thanks again for all your posts, and best wishes from the desert, it was only 113 today lol.

This car looks to be comming along good. I have taken a pretty good pause on mine due to my first child being born:sign12: and tring to re-side my house :violent1:

Excellent--so much closer!!

Wow that underside is impressive!

Great pictures for someone like me who wants to add the torque boxes to my car.

I think it's great that you've taken the time to add all of your detailed pictures to your thread, it helps a lot of us.........

Looking forward to this. It's been more than a minute since I tried to straighten metal with hammer and dolly. Can be time consuming, but the closer you get to straight the more rewarded you feel...despite the time investment. Of course, you have no issues with that from what we've all seen.

You ever figure out what happened there above the pinion snubber??

this is insane lol great to see another edmonton based build

Man watching you and your dad work your magic is just inspiring!!!!!!!!!!! Oh yes forgot to tell you I posted a few picts. in members gallery of car in my friends body shop last summer if you would like to see

It had an adjustable MP pinion snubber on the car, so I think it was to blame for all the damage.. Either it was launched hard all the time or it was so close to the snubber mount that it smashed into it on every bump while driving. I think it was a combination of both!