I recently purchased a 340 engine that was “completely rebuilt” that the original engine builder said would be a great engine. Engine had sat for a few years / never installed. Thought I would do some checking before putting it into my dart. Fortunately i did. The list of issues I found are too many to list. Tearing the engine completely down. Variations exist with the bore size in each cylinder. Hard to believe! The largest .030 with rust. I know plan on having it bored to .040. Is this too much for a 1971 340 block? Will I run into overheating problems? Thanks in advance for any information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 .040 Bore Okay?

- Thread starter Rover125

- Start date

-

No matter the year of block, no one can definitively tell you yes. If the machine shop you take it to is worth its weight in salt, it will have a sonic thickness checker. That will be the only true way to determine if your cylinders can handle the overbore.

mgoblue9798

Well-Known Member

I recently purchased a 340 engine that was “completely rebuilt” that the original engine builder said would be a great engine. Engine had sat for a few years / never installed. Thought I would do some checking before putting it into my dart. Fortunately i did. The list of issues I found are too many to list. Tearing the engine completely down. Variations exist with the bore size in each cylinder. Hard to believe! The largest .030 with rust. I know plan on having it bored to .040. Is this too much for a 1971 340 block? Will I run into overheating problems? Thanks in advance for any information.

Most of the time it would be ok, but core shift means it will have to be sonic checked to be 100% sure. If the block is already at .030 the machine shop may just hone it to .040 if it looks like it will clean up there.

My experience has been that overheating on a rebuild is usually more likely to be tune related than overbore.

FWIW all Blueprint engine chrysler small blocks are bored .040 as standard practice.

FSM says max .040. Lots of guys go .060. I was in the exact same boat as you. A so called nice .030 turned into an .040 overbore with one sleeve. Block came out great and is ready to be built again. Good luck with your build.

Sonic check it. That’s the only way to know for sure exactly where you’re at. I’ve had 340 blocks that weren’t worth jack as cast and fail @ a .030 over bore.

Sonic check it.

Sonic check it.

missing linc

Loose nut behind the wheel

I have heard of guys going to .080 on a 340, but as mentioned above, the block must be sonic checked by a good, trusted machine shop and you're taking a real risk. I've never gone beyond .040 personally.

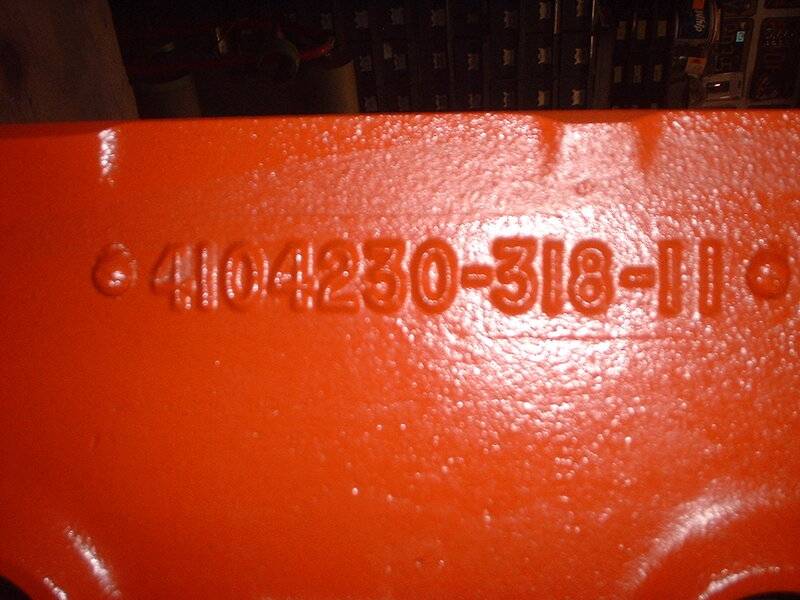

What is the production cast number after the 340 on the block? The higher the number the more chance of the cylinder being off set. Usually 340-1's are the best and there seems to be little problems with blocks up to 340 -8. Here is a example of a Race X block they were all casted as 318's this one was terrible 318-11. So bad the one lifter bore was missing a piece when casted. so the had to be welded and bushed

Last edited:

It is a 1.

Bobzilla

Well-Known Member

The website for Blueprint Engines specifies that the engine blocks are sonic tested, so they are making sure the block is capable before throwing in a .040 overbore, and that is on 360 based blocks.Most of the time it would be ok, but core shift means it will have to be sonic checked to be 100% sure. If the block is already at .030 the machine shop may just hone it to .040 if it looks like it will clean up there.

My experience has been that overheating on a rebuild is usually more likely to be tune related than overbore.

FWIW all Blueprint engine chrysler small blocks are bored .040 as standard practice.

I would use this as reinforcement that the block should be sonic tested and not as a free pass to bore any block .040 over stock size.

Rat Bastid

Dunamis Metron

It is a 1.

Does not matter what that number is.

If you want to know if it can go that big you need to sonic test it.

Anything else is a guess.

Inertia

Well-Known Member

Before sonic testing became avail, I built a few 0.060 over 340s, and after refreshing a few, I did notice one cylinder had a "funny/different" wear pattern on the wall.

Later, upon reflection, I concluded that was the cyl wall "flexing" , and scrutinized future cyl walls closely.

That was 60 over - the # matching motor in my Dart is 60 over, ran 12.5 pistons for years, refreshed a few times, no cyl wall distortion when inspected .

Still running well today !

Later, upon reflection, I concluded that was the cyl wall "flexing" , and scrutinized future cyl walls closely.

That was 60 over - the # matching motor in my Dart is 60 over, ran 12.5 pistons for years, refreshed a few times, no cyl wall distortion when inspected .

Still running well today !

cudamark

Well-Known Member

383's were notorious for bad core shift to where a .030 was a problem.Sonic check it. That’s the only way to know for sure exactly where you’re at. I’ve had 340 blocks that weren’t worth jack as cast and fail @ a .030 over bore.

Sonic check it.

Really! Good to know. I’d like to get a 383 one day to mess around with.

Thanks for all the replies. I will have the machine shop do the sonic thickness check.

mgoblue9798

Well-Known Member

The website for Blueprint Engines specifies that the engine blocks are sonic tested, so they are making sure the block is capable before throwing in a .040 overbore, and that is on 360 based blocks.

I would use this as reinforcement that the block should be sonic tested and not as a free pass to bore any block .040 over stock size.

Of course I agree. Reference to overbore was regarding his overheating concerns.

You can always sleeve it. Then you can make any cylinder the diameter you want. Machine shops can do 1 or all 8

Most of them I've seen can stand .100 over, but sonic testing will tell you all about it.

pishta

I know I'm right....

This has been debunked. The -11 was the cell it was cast in as they would cast more than 1 at a time or the 'core box'. You could find early '67 cast 340's with high "revision" numbers.What is the production cast number after the 340 on the block? The higher the number the more chance of the cylinder being off set. Usually 340-1's are the best and there seems to be little problems with blocks up to 340 -8. Here is a example of a Race X block they were all casted as 318's this one was terrible 318-11. So bad the one lifter bore was missing a piece when casted. so the had to be welded and bushed

View attachment 1716065025

View attachment 1716065026

View attachment 1716065027

340 casting "revision numbers" check in

Im calling BS to this " -1 is better than -8 (or even 15!)" hogwash. Id like to propose a theory that the suffix behind the 2780930-340-x is nothing more than a 4 based (?) casting cell number or casting position in the foundry, Not a core change or revision number. The sand cores were all...

www.forabodiesonly.com

www.forabodiesonly.com

Debunked by who? You. LOL The blocks we have here have different suffix numbers the 1's are always smooth with very little flashing on them. The higher numbers usually have large flashings and bad porosity. The end of the ladle always is the worst metal of the pour. I worked at a foundry in the Bethlehem steel in the 70's The best parts always came from the start of the ladle after scraping the slag from the top . The last of the pour was always dirty and cooler. It is usually the dirty iron not having the same flow Characteristics as it cools. The Higher numbers are the end of the pour. Also no quality control at the end of the pour testing the alloys.This has been debunked. The -11 was the cell it was cast in as they would cast more than 1 at a time or the 'core box'. You could find early '67 cast 340's with high "revision" numbers.

[/URL]

You can see low grade metal when decking the block the finish doesn't have the shine. Same with LS vs new Hemi's . Ray Barton pointed it out to us The Hemis are very bad iron compared to the LS You can literally see the difference. That 318-11 picture in a prior post was sonic tested before it had the lifter hole repaired. Usually those blocks can go to 4.125 and even up to 4.200. That block was only good to 4.080 . some may be OK but usually the high numbers have issues.

Had seen a 340-10 block piston take out the whole cylinder 5 . All that was there were the head studs hanging through the head. Strong blocks do not need hard block installed. You can listen to the debunked theories . I am only stating what I have seen and I have seen many destroyed engines over the years. The 358 sprint car builders always hunted for 340-1's stronger platform.

I trade two standard clean 340-6's and up blocks for one 340-1 , Bring them to me. Pishta

lead69

hopeless car junkie

To the op glad to see you are sonic testing it, I saw a virgin bore 340-1 block sonic checked and one of the major thrust walls was only .130 thick. The only blocks I have seen that consistently test good/thick everywhere are the 70-73 360 blocks with casting number 3418496.

I have a slant 6 block I just sonic tested and it is almost 3/8" on the major and minor thrust sides and over 1/4" on the opposite sides. All 6. Stupid thick.To the op glad to see you are sonic testing it, I saw a virgin bore 340-1 block sonic checked and one of the major thrust walls was only .130 thick. The only blocks I have seen that consistently test good/thick everywhere are the 70-73 360 blocks with casting number 3418496.

pishta

I know I'm right....

Thanks! That is the FIRST first-hand knowledge of this suffix purpose from a foundry member here. Ill gladly take this as fact now and PS my post.Debunked by who? You. LOL The blocks we have here have different suffix numbers the 1's are always smooth with very little flashing on them. The higher numbers usually have large flashings and bad porosity. The end of the ladle always is the worst metal of the pour. I worked at a foundry in the Bethlehem steel in the 70's The best parts always came from the start of the ladle after scraping the slag from the top . The last of the pour was always dirty and cooler. It is usually the dirty iron not having the same flow Characteristics as it cools. The Higher numbers are the end of the pour. Also no quality control at the end of the pour testing the alloys.

You can see low grade metal when decking the block the finish doesn't have the shine. Same with LS vs new Hemi's . Ray Barton pointed it out to us The Hemis are very bad iron compared to the LS You can literally see the difference. That 318-11 picture in a prior post was sonic tested before it had the lifter hole repaired. Usually those blocks can go to 4.125 and even up to 4.200. That block was only good to 4.080 . some may be OK but usually the high numbers have issues.

Had seen a 340-10 block piston take out the whole cylinder 5 . All that was there were the head studs hanging through the head. Strong blocks do not need hard block installed. You can listen to the debunked theories . I am only stating what I have seen and I have seen many destroyed engines over the years. The 358 sprint car builders always hunted for 340-1's stronger platform.

I trade two standard clean 340-6's and up blocks for one 340-1 , Bring them to me. Pishta

Rat Bastid

Dunamis Metron

Thanks! That is the FIRST first-hand knowledge of this suffix purpose from a foundry member here. Ill gladly take this as fact now and PS my post.

I have sonic tested many blocks over the years. The only and by only I mean ONLY consistent factor is the inconsistency of these blocks.

I have never even a correlation between casting numbs like that and lower series of numbers being better. Not once.

Since I did the testing myself, I call BULLshit on all of that.

And I did enough of them to see a trend if there was one.

EDIT: the only caveat to that is the early 360 blocks that were poured from 340 tooling. And I say you still sonic test everything because Chrysler was never perfect about stuff like that. That’s how you can have an early 72 model year Demon with a complete 68-71 340 in it. BTDT

Evidently You never compared the the numbers with the casting flaws. The 340-1's are a much cleaner casting. And no porosity at all. I remember seeing some of your work. It really wouldn't matter what the block looks like once you have your hands in it.I have sonic tested many blocks over the years. The only and by only I mean ONLY consistent factor is the inconsistency of these blocks.

I have never even a correlation between casting numbs like that and lower series of numbers being better. Not once.

Since I did the testing myself, I call BULLshit on all of that.

And I did enough of them to see a trend if there was one.

EDIT: the only caveat to that is the early 360 blocks that were poured from 340 tooling. And I say you still sonic test everything because Chrysler was never perfect about stuff like that. That’s how you can have an early 72 model year Demon with a complete 68-71 340 in it. BTDT

Rat Bastid

Dunamis Metron

Evidently You never compared the the numbers with the casting flaws. The 340-1's are a much cleaner casting. And no porosity at all. I remember seeing some of your work. It really wouldn't matter what the block looks like once you have your hands in it.

Really?? How many (exactly) blocks have you, with your own hands sonic tested?

My guess is zero. All mouth, but zero experience as a machinist.

You’ve never seen my work. And your opinion is worthless.

Once again, how many blocks have YOU sonic tested?

-