Hi all,

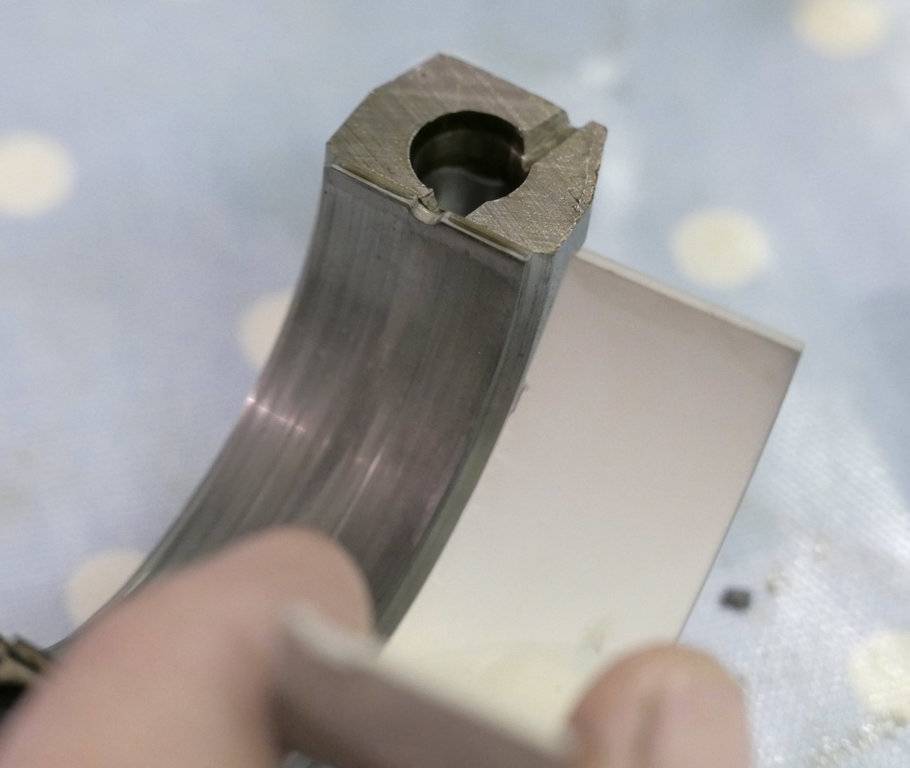

Hopefully you experienced engine builders can help me here. I am putting some bearings and rings etc into my 360. When I went to replace the con rod bearings I see that the Clevite 77 bearings that I have are slightly different to those I'm taking out. They fit perfectly otherwise, but the new bearings don't have the little cut out which I suppose allows/helps

oil circulation. I am sure I ordered the correct bearings, but I am unsure now whether to continue fitment or find some bearings with the cut out. I have attached a picture showing the original bearing vs the new, showing the missing slot. This is the first time I've been this deep into an engine so apologies if this is a stupid newbie question. I'd appreciate any help, thanks.

oil circulation. I am sure I ordered the correct bearings, but I am unsure now whether to continue fitment or find some bearings with the cut out. I have attached a picture showing the original bearing vs the new, showing the missing slot. This is the first time I've been this deep into an engine so apologies if this is a stupid newbie question. I'd appreciate any help, thanks.

Hopefully you experienced engine builders can help me here. I am putting some bearings and rings etc into my 360. When I went to replace the con rod bearings I see that the Clevite 77 bearings that I have are slightly different to those I'm taking out. They fit perfectly otherwise, but the new bearings don't have the little cut out which I suppose allows/helps