Not to burst your bubble, but cosmetic powder coating is not really suitable for exhaust applications. What you need is a high temp ceramic coating; without it, you'll be pulling the exhaust back off in less than a year.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

408 Build Thread

- Thread starter BrianT

- Start date

-

Leanna I trust your judgement and appreciate your advice. I also trust Tom who's a retired engineer who has been building exhausts for 30 years. When he tells me that he has powder coating left over from previous jobs I'm sure that it's going to be high temp. I had the pipes done on my two stroke motorcycle two seasons ago, and they still look like brand new. Temps near the head run 1000 + degree F. They're not ceramic either, just high temp black.

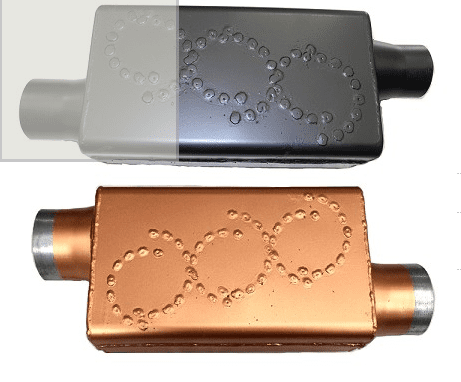

Edit: After reading the comment before your's, I guess I wasn't clear. The TTI headers are ceramic coated. Everything behind the headers will be coated in high temp black except the mufflers which are painted with high temp copper paint.

Edit: After reading the comment before your's, I guess I wasn't clear. The TTI headers are ceramic coated. Everything behind the headers will be coated in high temp black except the mufflers which are painted with high temp copper paint.

VOETOM

Well-Known Member

I want to share some new shots. As Leanna says, powder coating and heat are not the best of friends. For the mufflers, I am using Forrest Technical Coatings paint. They make it for painting indoor stoves and here is their data: Stove Bright® High Temperature Paint is the industry’s premier high temperature paint. It is formulated with a unique blend of heat resistant pigments in a silicone polymer resin that provides excellent color retention and film integrity in working temperatures up to 1200°F (650°C). Stove Bright® High Temperature Paint is designed for rapid curing and great working properties over ferrous metal surfaces. It is ideal for wood, pellet, and gas stoves as well as stove pipes, engines, engine manifolds, and many other metal substrates that are subject to high temperatures. Available in a wide range of colors to suit almost any need, and comes in both easy to use aerosol and brush-on formulas to accommodate any project."

This is some nice stuff. It will not adhere like powder (it is easier to scratch) but it can take the heat since the muffler shell will never see 1200 degrees F.

Here are some more shots with the tape off the bushings. They will be cut and flanges welded on soon (I hope).

This is some nice stuff. It will not adhere like powder (it is easier to scratch) but it can take the heat since the muffler shell will never see 1200 degrees F.

Here are some more shots with the tape off the bushings. They will be cut and flanges welded on soon (I hope).

VOETOM

Well-Known Member

I borrowed the idea from my pal "Dr. Gas" Boyd Butler who has successfully used this paint for several years.

Last edited:

mario03srt

Well-Known Member

deleted. My apologies to Brian.In normal traffic, it runs right at 200. When it hit the higher temps I was running 70 mph running down the highway at 3000 rpm for about twenty minutes. I don't plan on doing that too often.

Last edited:

I appreciate your input and maybe that information will help someone else on their build. But this is my build and for the THIRD time, the distributor that I'm running is fully electronic and has NO VACUUM CANNISTER.

...So I'm backing into a spot that my buddy saved for me and when I put the car into Park I could tell something wasn't right with the shifter. I was still in reverse. So I shut the engine off and put the parking brake on and got out like nothing was wrong (remember, people are still watching and staring). Turns out that the cable end had come loose from the shift lever at the transmission, right on top of my scorching hot header. At least it stayed together long enough for me to back into a spot.

I had another show to go to last Saturday, so I finally crawled underneath the Dart to reattach the shift cable. When I did, I saw that it was still attached?!?!? I followed the cable up and back and this is what I saw.

Seems like the cable got too close to the TTI header and melted the outer casing and the cable just came apart after that. Long story short, I just so happened to have another brand new cable laying around so I spent the next three hours installing it. Man was I sore the next day. You never miss your friends like you do when you're laying underneath the car and you need someone to grab a wrench for you, or push the cable in a little further. I must have crawled out from under the car at least twenty times. I slipped some heat reflective tubing over the new cable and made sure that it wasn't anywhere near the header again.

I had been meaning to adjust the shifter because the 2-3 shift required that you hit the shifter twice for some reason? I read the instructions again and they said that the cable needs be installed with the trans and shifter in first gear. I'm pretty sure everything was in Park when we hooked it up. I'm hoping that's the problem. Of course, the hardware that holds the cable to the trans lever is long gone, probably somewhere on the road to the show. I'll have to try and find a more permanent way to connect the cable.

While I was under there I also noticed that the Lokar kickdown cable had quite a bit of slack in it, so when I got back up top, I re-adjusted the cable. That really helped with the shift points on the transmission. It stayed in each gear a little longer and when it did shift, it did it a little more firm than before. I think it was just shifting out so early before that it wasn't building up any line pressure.

I haven't updated this thread lately because I haven't been doing much to the car besides driving it! Tom came over a couple of weeks ago and we put on the 3" mandrel bent exhaust along with his hi flow mufflers. They sound real nice but we've got to work on getting tail pipes on it to get the exhaust out the back. I bought some 3" tailpipes from Heartthrob Exhaust that are meant for a Camaro/Nova (I know, blasphemy!!!) that Tom thinks we can cut up and make work for my application. He came over the other night and that is going to be a winter project. It will involve moving some brake lines and maybe even rotating the calipers out of the way. We shall see. Here's a pic of the exhaust installed.

I've been playing around with the timing and think that I've got it finally dialed in. I was getting a little concerned because we originally set it up at 20 degrees intial 35 total and I've been driving it that way. I bumped it up a degree and it ran better, so I bumped it up another. Currently running 22/37 degrees and it seems to like it real well.

I'm taking the car to a chassis dyno this afternoon and they are going to dial in my jetting and metering rods using an air/fuel gauge. It's a friend of a friend thing and he's doing it in his shop after hours at a discounted rate. I'll try to post up a video and some numbers tonight if I'm not too busy out burning tires!

I've been playing around with the timing and think that I've got it finally dialed in. I was getting a little concerned because we originally set it up at 20 degrees intial 35 total and I've been driving it that way. I bumped it up a degree and it ran better, so I bumped it up another. Currently running 22/37 degrees and it seems to like it real well.

I'm taking the car to a chassis dyno this afternoon and they are going to dial in my jetting and metering rods using an air/fuel gauge. It's a friend of a friend thing and he's doing it in his shop after hours at a discounted rate. I'll try to post up a video and some numbers tonight if I'm not too busy out burning tires!

doogievlg

Well-Known Member

I haven't updated this thread lately because I haven't been doing much to the car besides driving it! Tom came over a couple of weeks ago and we put on the 3" mandrel bent exhaust along with his hi flow mufflers. They sound real nice but we've got to work on getting tail pipes on it to get the exhaust out the back. I bought some 3" tailpipes from Heartthrob Exhaust that are meant for a Camaro/Nova (I know, blasphemy!!!) that Tom thinks we can cut up and make work for my application. He came over the other night and that is going to be a winter project. It will involve moving some brake lines and maybe even rotating the calipers out of the way. We shall see. Here's a pic of the exhaust installed.

View attachment 1715091109

I've been playing around with the timing and think that I've got it finally dialed in. I was getting a little concerned because we originally set it up at 20 degrees intial 35 total and I've been driving it that way. I bumped it up a degree and it ran better, so I bumped it up another. Currently running 22/37 degrees and it seems to like it real well.

I'm taking the car to a chassis dyno this afternoon and they are going to dial in my jetting and metering rods using an air/fuel gauge. It's a friend of a friend thing and he's doing it in his shop after hours at a discounted rate. I'll try to post up a video and some numbers tonight if I'm not too busy out burning tires!

Seems like a lot of initial but if it's liking it then have at it haha

360duster

Well-Known Member

nice stuff.....i run 25° initial, 35° total with my 408. they like a lot of initial, much cleaner idle, no starting problems here. Of course you have to check the total advance, my distributor is adjusted to 10° mechanical advance.

Have fun!

Michael

Have fun!

Michael

We are going to play around with the timing a little today on the dyno. I wanted to have it set as close as possible so that we didn't spend a whole lot of time on the ignition. I'm mainly going to get the carb dialed in.

doogievlg

Well-Known Member

We are going to play around with the timing a little today on the dyno. I wanted to have it set as close as possible so that we didn't spend a whole lot of time on the ignition. I'm mainly going to get the carb dialed in.

This is exactly why I am taking my engine to a dyno before it goes in my car. I got tired of changing one little thing then taking it back out onto the street and seeing how it felt. Much easier with the dyno.

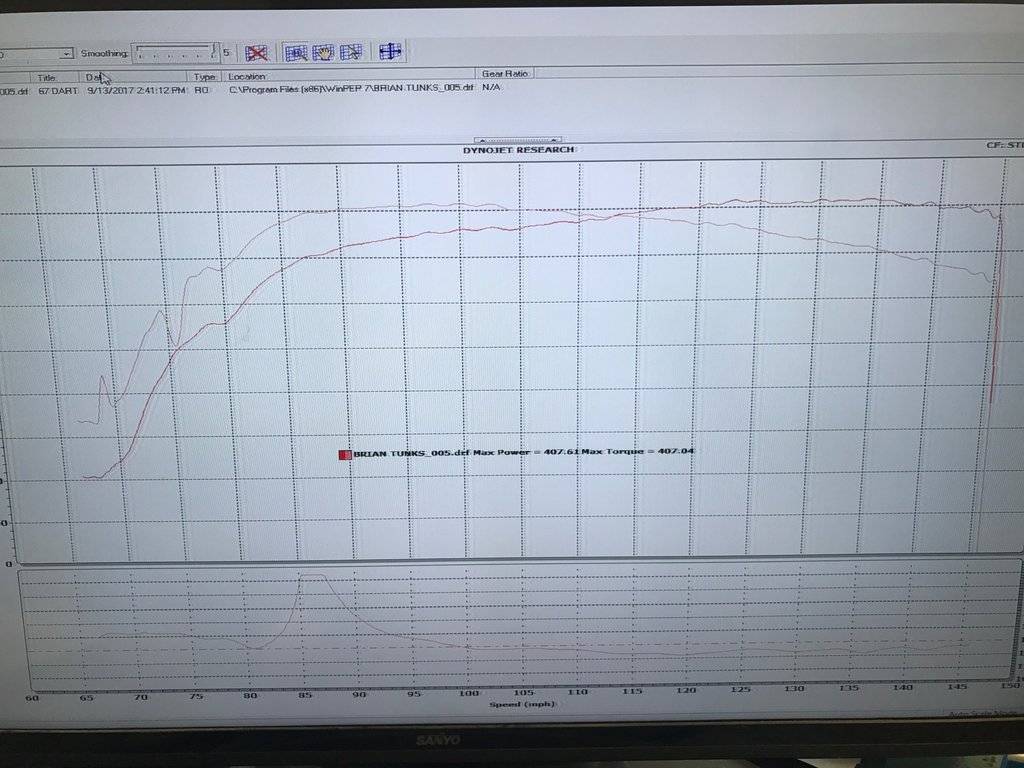

I went to the dyno yesterday to get my carb dialed in and we didn't even touch it! I went there expecting to pull around 350 to the wheels (500 at the crank times 70 percent for drive train loss) and started with 367 on the first pull. We took a little timing out of it and played with some different timing curves. We ended up with a best of 407 hp and 407 ft/lbs. The carb was pretty close through out the whole pull and didn't need any jetting changes at all.

Here's a short video

Here's a short video

360duster

Well-Known Member

wow, that´s cool.....so what total timing made best power? I can´t see it from the graph, at what rpm is the torque peak?

thanks Michael

thanks Michael

stixx

Well-Known Member

I'd call that a square engine (407 / 407). Well done!

After all the playing around we did, we went back to 22 degrees intial with 15 degrees advance for a total of 37. We did disconnect the vacuum advance that I had hooked up as they said it was pulling the timing up into the mid forties. It runs fine without it hooked up. I didn't catch when peak torque was made but the pulls were made to about 6500 and he told me that I should be shifting around 6200. I looked at the printout he gave me and it was in the mph mode when he printed so all I know is that I made peak torque at 123 mph!!!

I also ran the car by some truck scales on the way home and it weighed in at 3400 lbs. That's about what I expected with the Dana rear and full interior with sound deadener.

I also ran the car by some truck scales on the way home and it weighed in at 3400 lbs. That's about what I expected with the Dana rear and full interior with sound deadener.

360duster

Well-Known Member

thank you very much. I´m running similar heads, i´ll try some more total timing next time out.

Michael

Michael

Lonewolf3165

Living the Dream!

Great job Brian! I'm sure you're pleased. Very happy for you!

mario03srt

Well-Known Member

Brian,

Looks like a supercharged engine dynochart. Love the area under the curve!

Marion

Looks like a supercharged engine dynochart. Love the area under the curve!

Marion

fishy68

Tyr Fryr's Inc.

Great numbers Brian. Should be a ton of fun to drive

I haven't updated the thread for a while because I haven't been doing much except driving the car on the weekends and enjoying it! Last weekend I did change out the break in oil to VR1 30wt and put on a new Napa Gold filter. I also drained the break in oil out of the Strange rear end and put in some Valvoline synthetic gear lube.

@VOETOM came by and made some changes to my transmission, but I'm gonna have to let him explain them. He wasn't happy with the 2-3 shift overlap so we spent a couple of hours swapping out a couple of springs and making adjustments to the kick down linkage and now we think we have it shifting pretty good.

Over the coming winter we are going to clean up the mess that is the back half of the car. I have an axle seal thats leaking and a few misc parts that weren't installed properly for the sake of getting the car back on the road. We are also going to make some changes to the location of the rear calipers in order to make room for the 3" tail pipes that I bought at Tom's reccomendation. This car is a work in progress.

@VOETOM came by and made some changes to my transmission, but I'm gonna have to let him explain them. He wasn't happy with the 2-3 shift overlap so we spent a couple of hours swapping out a couple of springs and making adjustments to the kick down linkage and now we think we have it shifting pretty good.

Over the coming winter we are going to clean up the mess that is the back half of the car. I have an axle seal thats leaking and a few misc parts that weren't installed properly for the sake of getting the car back on the road. We are also going to make some changes to the location of the rear calipers in order to make room for the 3" tail pipes that I bought at Tom's reccomendation. This car is a work in progress.

-

Similar threads

- Replies

- 75

- Views

- 3K

- Replies

- 39

- Views

- 2K

- Replies

- 30

- Views

- 2K

- Replies

- 78

- Views

- 3K