myduster360

Well-Known Member

Things are moving right along. The Bellhousing is in the machine shop getting cut.

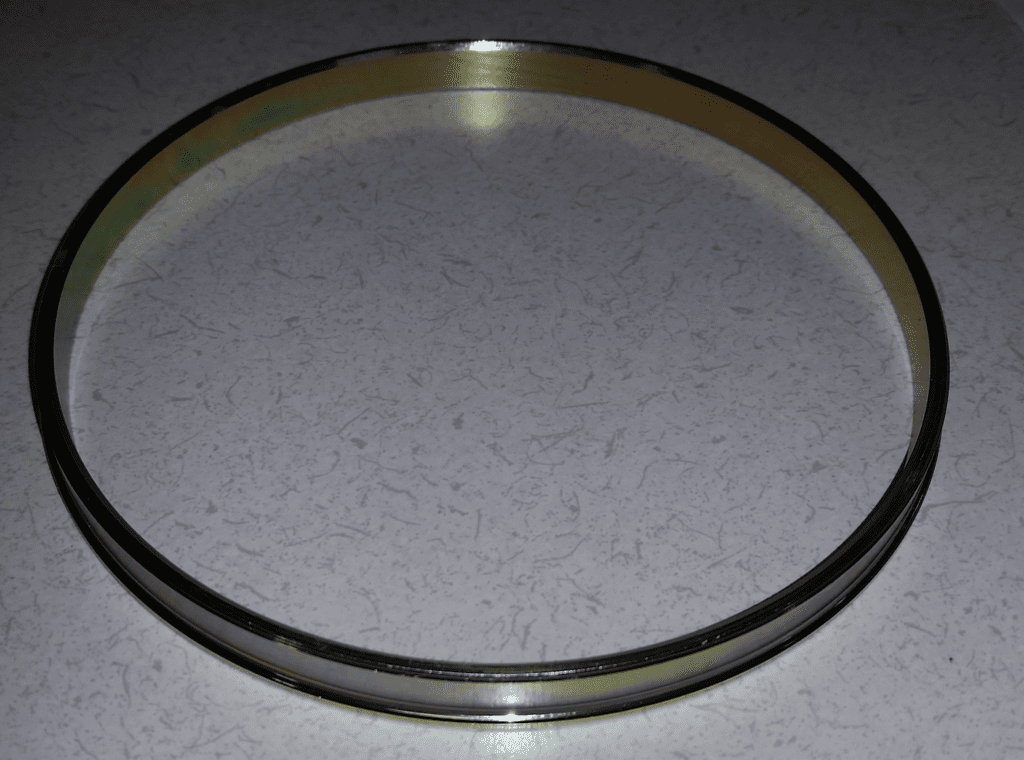

The Adapter ring came in yesterday. Not bad for $30 considering its fully machined.

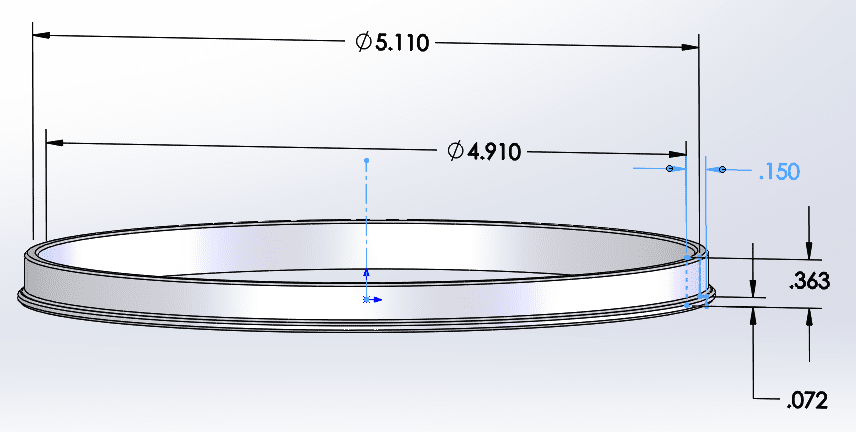

Here's how it measures. I test fitted it on my T5 and its nice a snug

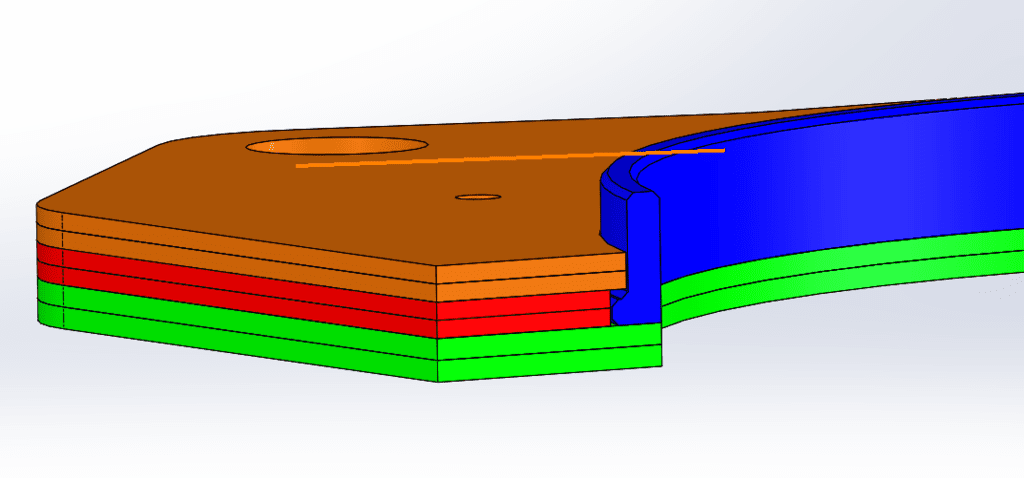

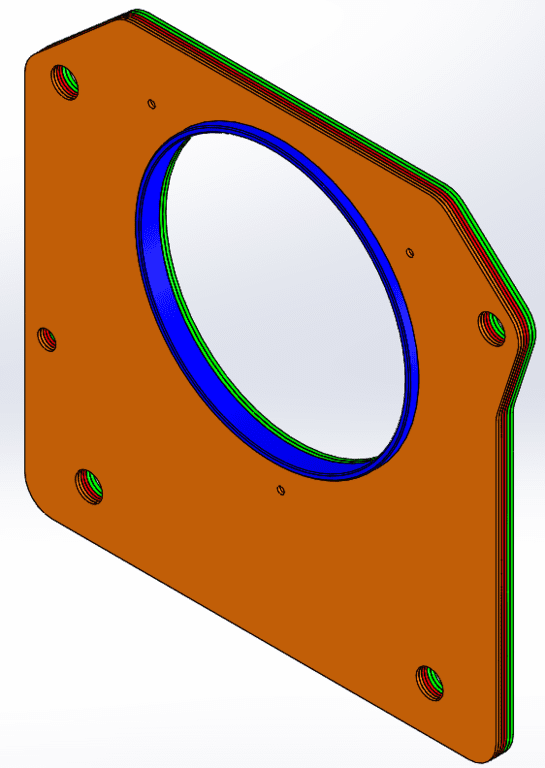

I tweaked my design of the adapter plate sheets to fit the adapter ring dimensions. There are 3 different sheets that are identical except for their center hole.

The 3 different diameters are 5.220"(red), 5.125"(orange), 4.91"(green)

The Adapter ring came in yesterday. Not bad for $30 considering its fully machined.

Here's how it measures. I test fitted it on my T5 and its nice a snug

I tweaked my design of the adapter plate sheets to fit the adapter ring dimensions. There are 3 different sheets that are identical except for their center hole.

The 3 different diameters are 5.220"(red), 5.125"(orange), 4.91"(green)