Juhosaphat

Member

So a while back, a co-worker of mine at Les Schwab told me about a buddy of his that had this car sitting under a car port. It'd been there for years because the guys brother bought it, got drunk one night, tore it apart to blast/paint everything, and stopped at the blasting part. No paint, no re-assembly. That was 20+ years ago probably.

Fast forward to about six months ago, the guys buddy stops by the store to see him and he's not working. I remembered the car and asked him about it. It ended up being a 72' Duster/Twister. Full tube chassis car, narrowed D60 with all new Strange axles, Strange spool, and Richmond 5.52 gears. The guy who built it way back when apparently built about 8-10 cars the same way. The cage is over built and will most likely have to be modified as it's more of an open body type cage in a full body car.

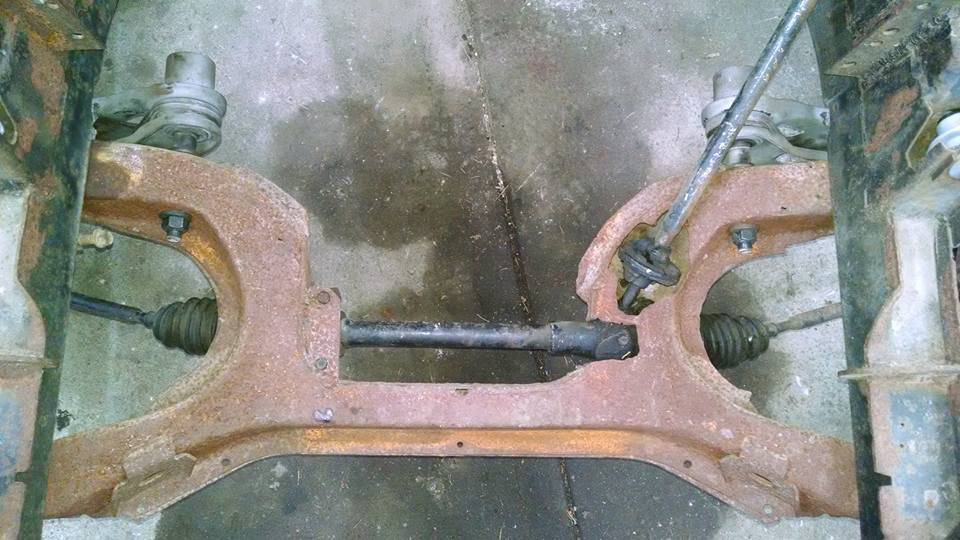

It was being setup for coilover suspension in the front. It was setup for a Mustang II rack and pinion. Not very well (See the picture of the factory K-member modification to fit the rack and pinion, scary!) at that. It came with a good amount of tin pieces which I will use for stencils when re-doing the tin for the interior and the fire wall.

It came with a ridiculous amount of parts as well including:

One virgin 440 block

One virgin shortblock 440

One complete rotating assembly with factory forged crank, six pack rods, and unknown flattops

One set of 516 heads torn down with everything there, but rough shape

Two sets of factory rocker shafts and rockers, usable shape

One 727 trans core with rebuild kit and shift kit brand new in boxes

Edelbrock Torker manifold brand new in box with new in box valley pan

Custom header kit

All factory glass minus the front windshield

Demon front clip and factory Duster clip

Brand new Mustang II manual rack and pinion

A whole lot more that I know I'm forgetting.

The current plan is to assemble it and build a mild 440 to get it going down the track and get a feel for it while dialing the suspension in. Then a big dollar 543 build down the road. I will be sure to post as many pictures as I can as I update.

Today I hung the front fenders, installed the Duster clip so I can start getting measurements to fab up a core support as it did not come with it. I also test fitted the master cylinder bracket and master cylinder. I'm loosely assembling what I can so I can figure out where everything goes before blasting/painting all the smaller parts.

I got the passenger side trim and quarter window installed as well as the weatherstrip for that side. This thing is going to be quite a project, but it'll be completely badass once it's all done.

Fast forward to about six months ago, the guys buddy stops by the store to see him and he's not working. I remembered the car and asked him about it. It ended up being a 72' Duster/Twister. Full tube chassis car, narrowed D60 with all new Strange axles, Strange spool, and Richmond 5.52 gears. The guy who built it way back when apparently built about 8-10 cars the same way. The cage is over built and will most likely have to be modified as it's more of an open body type cage in a full body car.

It was being setup for coilover suspension in the front. It was setup for a Mustang II rack and pinion. Not very well (See the picture of the factory K-member modification to fit the rack and pinion, scary!) at that. It came with a good amount of tin pieces which I will use for stencils when re-doing the tin for the interior and the fire wall.

It came with a ridiculous amount of parts as well including:

One virgin 440 block

One virgin shortblock 440

One complete rotating assembly with factory forged crank, six pack rods, and unknown flattops

One set of 516 heads torn down with everything there, but rough shape

Two sets of factory rocker shafts and rockers, usable shape

One 727 trans core with rebuild kit and shift kit brand new in boxes

Edelbrock Torker manifold brand new in box with new in box valley pan

Custom header kit

All factory glass minus the front windshield

Demon front clip and factory Duster clip

Brand new Mustang II manual rack and pinion

A whole lot more that I know I'm forgetting.

The current plan is to assemble it and build a mild 440 to get it going down the track and get a feel for it while dialing the suspension in. Then a big dollar 543 build down the road. I will be sure to post as many pictures as I can as I update.

Today I hung the front fenders, installed the Duster clip so I can start getting measurements to fab up a core support as it did not come with it. I also test fitted the master cylinder bracket and master cylinder. I'm loosely assembling what I can so I can figure out where everything goes before blasting/painting all the smaller parts.

I got the passenger side trim and quarter window installed as well as the weatherstrip for that side. This thing is going to be quite a project, but it'll be completely badass once it's all done.