Landons65Dart

Proud Mopar Owner

So I decided to turbocharge my '65 Dart's stock 225 slant six. It ran great! 15 pounds of boost and it could beat out stocker small blocks. It started smoking quite a bit, and burned 2 quarts of oil in a day. Pulled the motor and decided I wanted to do a twin turbo small block, but then recently changed my mind back to a hypo turbo slant six. Discovered my motor is a factory replacement (no vin) and its a '70 motor, which by chance happens to be the best motor and head to build. Started dissecting it and found the head gasket was blown in 3 places... Thought that was the problem.

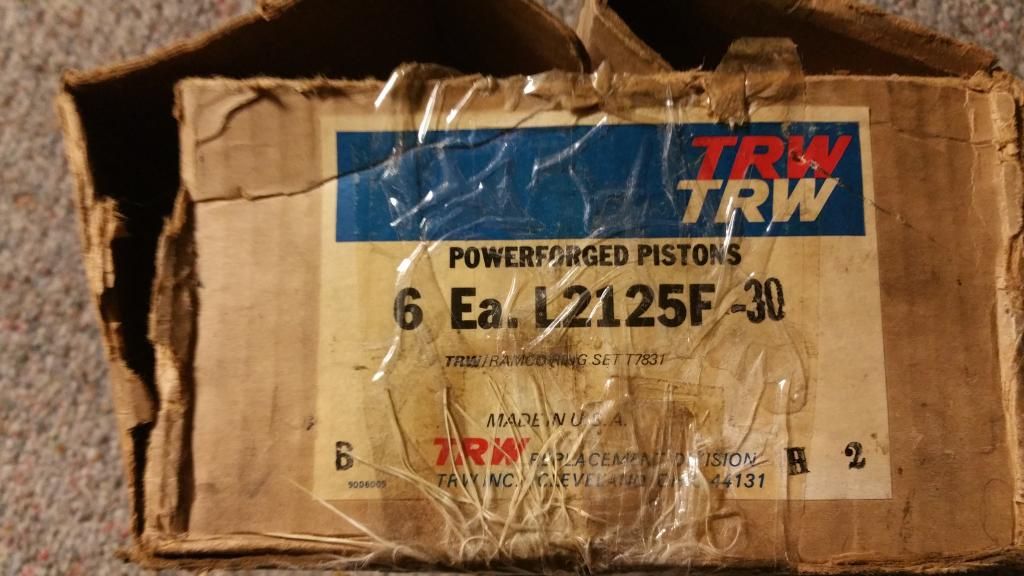

I pulled the oil pan and flipped the motor and pulled the oil tube off. When it came off, chunks of metal fell out of it. Aluminum chunks. Knocked all the Pistons out and didn't find one piston damaged.... but ALL SIX Pistons were completely broken/cracked. At least this was just for fun. This time I'm going all out on the build. No shortcuts.

View attachment image.jpg

I pulled the oil pan and flipped the motor and pulled the oil tube off. When it came off, chunks of metal fell out of it. Aluminum chunks. Knocked all the Pistons out and didn't find one piston damaged.... but ALL SIX Pistons were completely broken/cracked. At least this was just for fun. This time I'm going all out on the build. No shortcuts.

View attachment image.jpg