I need to wire in the alternator & regulalator on my sons 72 416 Duster,

just not sure if i need to do anything differently since the battery has been relocated to trunk area, I have the +BAT terminal of the alternator running back to the trunk area to the battery, the amp guage is gone and bypassed entirely, i have an 8 guage running from disconnect in trunk up to BAT post on starter relay and then another wire feeding the power to a universal 12 circuit painless box (with fusible link) i am still running the original bulkhead and stock ignition switch and forward engine harness. the only connections im using now are the brown & blue tied together to feed the mallory box (small red wire) and the yellow to the starter relay.

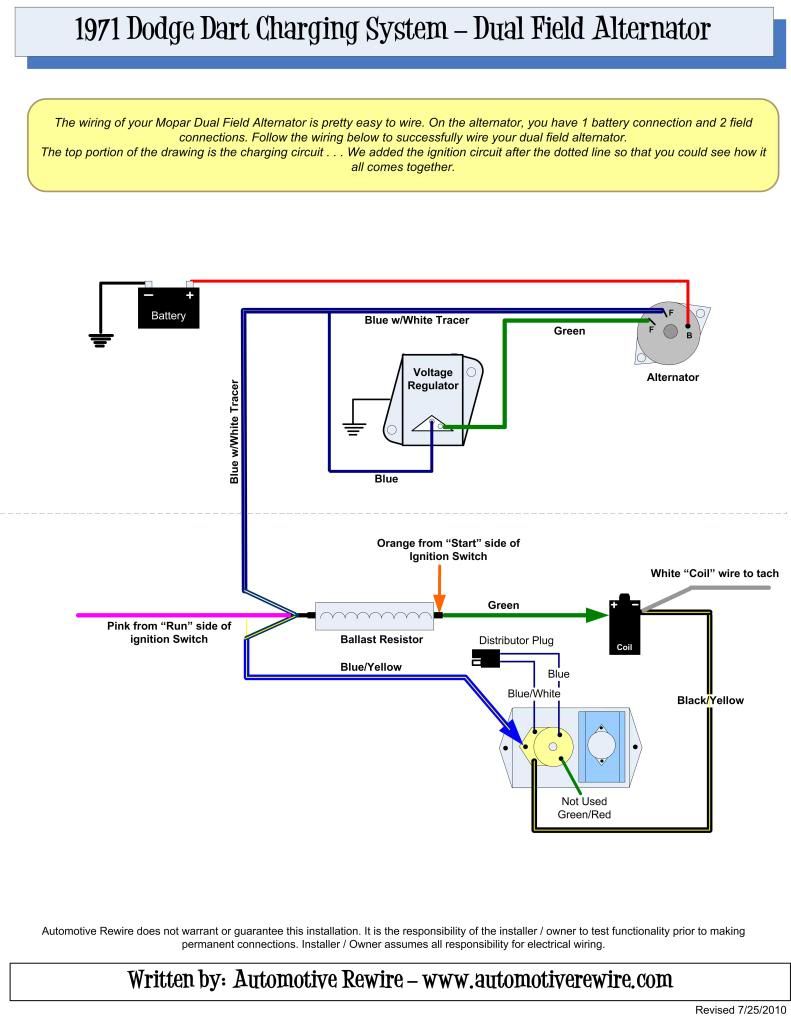

how should the 2 field terminals get wired in with the voltage regulator ?

thanks

340

just not sure if i need to do anything differently since the battery has been relocated to trunk area, I have the +BAT terminal of the alternator running back to the trunk area to the battery, the amp guage is gone and bypassed entirely, i have an 8 guage running from disconnect in trunk up to BAT post on starter relay and then another wire feeding the power to a universal 12 circuit painless box (with fusible link) i am still running the original bulkhead and stock ignition switch and forward engine harness. the only connections im using now are the brown & blue tied together to feed the mallory box (small red wire) and the yellow to the starter relay.

how should the 2 field terminals get wired in with the voltage regulator ?

thanks

340