thesiren74

Well-Known Member

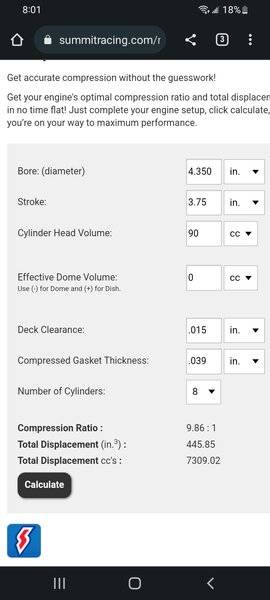

Not knowing cylinder head cc or gasket.

For $375 i don’t have a problem going with new pistons. Learning to calc compression ratio has actually been fun. But I apparently need to go back to the drawing board on the cam now too.As everyone has said wrong cam and wrong pistons. If you really have to re-use the pistons just run it with a stock cam till you get the coin for a rebuild. With that cam and pistons and converter you will just have no fun.

How did you figure deck clearance?Oops forgot the +9.00cc so 9.14

I have a question. Would a 7.5:1 compression 440 that made 427 lb-ft @ 2,500 rpm and 287 hp @ 4,400 rpm be any fun in a Dart with a 2,500 stall converter using 3.73 gears and 275/60/15 tires?As everyone has said wrong cam and wrong pistons. If you really have to re-use the pistons just run it with a stock cam till you get the coin for a rebuild. With that cam and pistons and converter you will just have no fun.

Call a cam manufacturer to get a recommendation. I'm not discounting anyone's knowledge or experience here, but the cam manufacturers design cams for a living, 40 hours a week. A lot of well-known engine builders have never spec'ed a cam in their lives. They leave it to the pros.For $375 i don’t have a problem going with new pistons. Learning to calc compression ratio has actually been fun. But I apparently need to go back to the drawing board on the cam now too.

Thank you. I will definitely be going this route vs trying to learn all about cams myselfCall a cam manufacturer to get a recommendation. I'm not discounting anyone's knowledge or experience here, but the cam manufacturers design cams for a living, 40 hours a week. A lot of well-known engine builders have never spec'ed a cam in their lives. They leave it to the pros.

The best results are achieved by being 100% honest with the person to whom you speak. Don't say the car's lighter than it is, or the heads are better than they are. Tell them what you have and what you'd like to accomplish. Be realistic: You won't get a reliable 8,000RPM out of your current base componentry, so don't tell them you want a 7,500RPM shift point. With your goals, you'll probably be steered into a flat-tappet "shelf" cam (something they stock, as opposed to a custom grind) but if that's what they say will work, run it. Don't try to improve on their suggestions unless it involves calling a different cam company.

Download a cam request form from one of the manufacturers (Comp had a good one) so you know what kind of questions you'll be asked. Don't e-mail them, call. I've had two cams designed and shipped in the time since I requested a previous cam, which I did via e-mail and have never heard a peep. I no longer need it, but I still hope someday they'll respond.

Not a mopar but, years ago had a 1977 chevy concours 305, 8.5:1 with a two barrel and 2.73 gear. Stock was 145 hp. Changed to 4 barrel and cam to edelbrock performer. If running engine out and manual shift from first to second would bark back tire at around 60 mph. Was not a race car by any means but was still a fun little car. So 287 hp with that stall and rear gear in a small car would still be fun.I have a question. Would a 7.5:1 compression 440 that made 427 lb-ft @ 2,500 rpm and 287 hp @ 4,400 rpm be any fun in a Dart with a 2,500 stall converter using 3.73 gears and 275/60/15 tires?

I think (just my BS talking) what he has on the drawing board will make more than that.

To someone use to driving a stock small block, it would be a handful for sure, certainly very fun to drive.I have a question. Would a 7.5:1 compression 440 that made 427 lb-ft @ 2,500 rpm and 287 hp @ 4,400 rpm be any fun in a Dart with a 2,500 stall converter using 3.73 gears and 275/60/15 tires?

I think (just my BS talking) what he has on the drawing board will make more than that.

This someone is used to driving a tired slant 6To someone use to driving a stock small block, it would be a handful for sure, certainly very fun to drive.

Call a cam manufacturer to get a recommendation. I'm not discounting anyone's knowledge or experience here, but the cam manufacturers design cams for a living, 40 hours a week. A lot of well-known engine builders have never spec'ed a cam in their lives. They leave it to the pros.

Not to argue at all, but it may be easier to shave the heads, yes? Direct Connection Performance Handbook recommends this and he wouldn't need to tear down the short block. 0.060 off the heads and correct about from the intake surfaces will bring up to ~9.8, I believe it says.If you just intend for this to be a low dollar street engine I wouldn't even bother buying pistons. Just cut the deck height on the block down. I've done this dozens of time and it will raise the compression faster than trying to find a new piston that you probably don't really need in the first place. I wrote a pretty in depth thread or reply on here on the forum about how to do it along with every detail you need to know doing it this way.

Tom