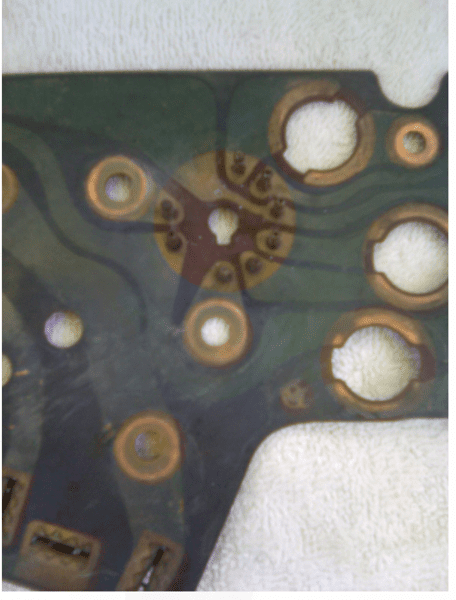

The board looks kinda dirty, corroded. It might be right there in the connector. Here's an old thread that is very good about refurbishing the board EDIT I can no longer find that old thread...............

Anyhow the cluster pins for the connector are originally riveted/ swedged in place, not soldered. Clean it with whatever means, scrape, exacto knife, maybe one of those toothbrush sized stainless welding brushes (welding supply stores and MAYBE HD/ Lowes) Get some liquid flux DESIGNED for electrical off ebay, etc, and solder the connector pins. The thread "I cannot find" even detailed putting copper wire inside the pins that were broken to strengthen them and then re--solder

GENERALLY what goes wrong.............

FIND the common ground point for the lighting. This is bolted to the cluster housing which is only "accidently" grounded by means of the cluster mounting screws. So add a pigtail to this, bolt it to the dash frame or column support

The gauges can loose connections where they connect to the board. Loosen/ tighten the gauge studs to "scrub" the copper connections. Clean up the copper around the light sockets. Bend and clean the socket fingers, and if they are too bad you may have to find replacements. TEST the board by jumpering power to the lights, etc.

The path for the lighting is a "trick". Power to the dash dimmer comes from the tail circuit so that has to work FIRST. Then through the dimmer control, and next through the INST fuse and out on orange wires to all dash dimmer controlled lighting. So that fuse clip, the wire connections, and dimmer itself can be a problem

GAUGE LIMITER. Do you have a 3 terminal fuel gauge? If so, the gauges limiter/ regulator is INSIDE the fuel gauge. If it works "fine." If not there are workarounds. You can test gauges by applying 12V to the common ignition supply line, then substituting known resistors at the gauge sender connections, which represent L, medium or 1/2, and H or Full