Also, where is the cam installed? Was it degreed and installed per the cam card?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Built 360 Having a Tantrum

- Thread starter Dodge72

- Start date

-

Dodge72

Odd one out

Uhhhh.....what kinda gas does he run in that thing?

91 non-ethanol.

91 non-ethanol.

I "would think" that'd be enough with those compression test readings. IMO, they are still a little low for that cam to be installed at 106 ICL, which is where it should be, I believe.

Dodge72

Odd one out

Can was lined up dot to dot to answer your other question. Wasn't degreed, and it probably should've but we didn't have that knowledge to do it.

Dodge72

Odd one out

And oh yes, the intake pushrod on #1 was bent slightly. But we got an adjustable pushrod so once the head gets put back on, we will measure them properly.

According to Comp, the rocker adjustment is supposed to be 0 lash, with one full turn after that. We will have to go through everything and ensure that that is correct.

According to Comp, the rocker adjustment is supposed to be 0 lash, with one full turn after that. We will have to go through everything and ensure that that is correct.

nm9stheham

Well-Known Member

Those pistons appear to be KB quench head type pistons with the raised pad above the eyebrows, like KB373's. Should be around 9.5 static CR in an unmilled LA360 block with typical, unmilled LA open heads and a .039" thick head gasket. So 91 octane is doable IMHO (if the deck and heads are stock-ish).

That static CR also calls into question the passenger side cranking cylinder pressures; they are 15-20 psi low for that cam and cylinder combination at an altitude around Shelton WA. You would have to be up on top of the Olympic Mtns there to get cranking compressions that low... or the cam is quite retarded in timing. The compression numbers on #3 and #7 would be what is expected for that SCR, cam, etc.

All of this cranking pressure variation means IMHO that the cam timing NEEDS to be properly checked.

The bent pushrod on #1 is of concern. Did the BF rev this thing pretty high when he left that stop sign? The 1st suspect to bend that pushrod is valve float and the lifter's pumping up. So that leads to asking about what valve springs are in there. You also NEED to check piston to valve clearance in this engine; the cam is not extreme in terms of lift or duration but it still needs checking. That has to be done in a certain way with hydraulic lifters to be accurate.

That static CR also calls into question the passenger side cranking cylinder pressures; they are 15-20 psi low for that cam and cylinder combination at an altitude around Shelton WA. You would have to be up on top of the Olympic Mtns there to get cranking compressions that low... or the cam is quite retarded in timing. The compression numbers on #3 and #7 would be what is expected for that SCR, cam, etc.

All of this cranking pressure variation means IMHO that the cam timing NEEDS to be properly checked.

The bent pushrod on #1 is of concern. Did the BF rev this thing pretty high when he left that stop sign? The 1st suspect to bend that pushrod is valve float and the lifter's pumping up. So that leads to asking about what valve springs are in there. You also NEED to check piston to valve clearance in this engine; the cam is not extreme in terms of lift or duration but it still needs checking. That has to be done in a certain way with hydraulic lifters to be accurate.

Wyrmrider

Well-Known Member

not the white smoke problem but check the valve stem seals

and how do the plugs look with all that *** on them

and how do the plugs look with all that *** on them

Dodge72

Odd one out

Those pistons appear to be KB quench head type pistons with the raised pad above the eyebrows, like KB373's. Should be around 9.5 static CR in an unmilled LA360 block with typical, unmilled LA open heads and a .039" thick head gasket. So 91 octane is doable IMHO (if the deck and heads are stock-ish).

That static CR also calls into question the passenger side cranking cylinder pressures; they are 15-20 psi low for that cam and cylinder combination at an altitude around Shelton WA. You would have to be up on top of the Olympic Mtns there to get cranking compressions that low... or the cam is quite retarded in timing. The compression numbers on #3 and #7 would be what is expected for that SCR, cam, etc.

All of this cranking pressure variation means IMHO that the cam timing NEEDS to be properly checked.

The bent pushrod on #1 is of concern. Did the BF rev this thing pretty high when he left that stop sign? The 1st suspect to bend that pushrod is valve float and the lifter's pumping up. So that leads to asking about what valve springs are in there. You also NEED to check piston to valve clearance in this engine; the cam is not extreme in terms of lift or duration but it still needs checking. That has to be done in a certain way with hydraulic lifters to be accurate.

Mentioned earlier he lined the cam up dot to dot. We had no know-how on degreeing cams and no to be safe we did not attempt to do so. According to Comp, this cam has 4 degrees of advance ground in already, although that may not be enough. We haven't ripped the timing cover off just yet to verify chain condition or current timing.

I've seen the method of putting in putty and the head temporarily to check clearance, we can do so. I'll have to look up how to do so with hydraulic lifters...

And no he didn't, no more than 3-4 grand to shift (manual valve body 727).

As far as valve springs I'm not sure specifically what brand. They are double springs however.

Wishing that this car came with a parts file lol.

nm9stheham

Well-Known Member

Dual springs with damper... that is good. Gotta say that the upper end of that damper (the flat coil) looks twisted.....and the wear marks on it agree IMHO.

The bent pushrod could be an indicator. I would inspect the retainer to guide clearance VERY closely.

Dodge72

Odd one out

How do you check if it's twisted? I guess it's my untrained eye that I don't see it.

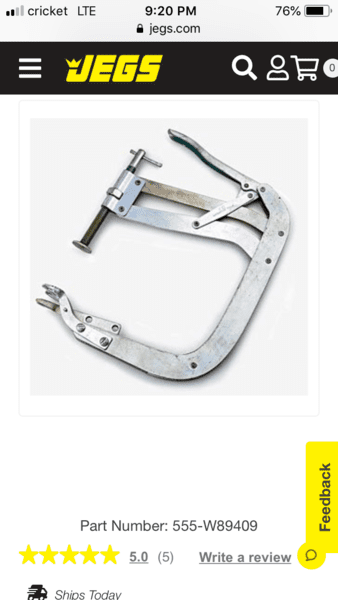

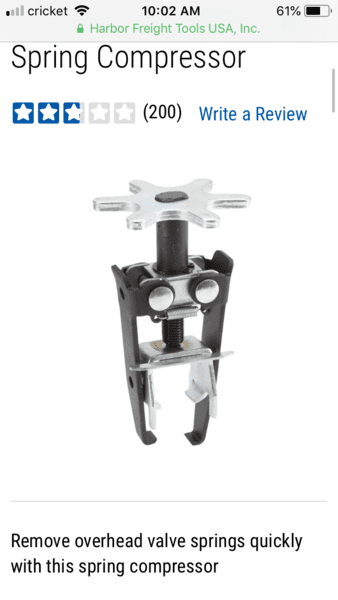

Well we tried to take #1s valve springs off and couldn't compress them with your overhead valve tool or the clamp type tool. They worked on my stock 360 springs so I guess they need way more force to compress. He's gonna take it to class (automotive student) and see if there's any other tools he can use on it. I'll tell him to check the clearance from retainer to guide.

Well we tried to take #1s valve springs off and couldn't compress them with your overhead valve tool or the clamp type tool. They worked on my stock 360 springs so I guess they need way more force to compress. He's gonna take it to class (automotive student) and see if there's any other tools he can use on it. I'll tell him to check the clearance from retainer to guide.

The C clamp should work.......unless it's a cheap POS. No offense.

Baxter61

Well-Known Member

whoops, thought you were closer for some reason

whoops, thought you were closer for some reason

Now that's a nice offer.

Wyrmrider

Well-Known Member

How do you tell

that dampner should be up against the retainer instead of between the top coils- that's gotta hurt and is hurt

good tip on checking retainer to guide

now you gotta check everything

that dampner should be up against the retainer instead of between the top coils- that's gotta hurt and is hurt

good tip on checking retainer to guide

now you gotta check everything

nm9stheham

Well-Known Member

Just look at the angle of the lower edge of the top coil in the damper ribbon.... it is at a different angle than the other coils of the damper. It's not sitting against the retainer right.How do you check if it's twisted? I guess it's my untrained eye that I don't see it.

Well we tried to take #1s valve springs off and couldn't compress them with your overhead valve tool or the clamp type tool. They worked on my stock 360 springs so I guess they need way more force to compress. He's gonna take it to class (automotive student) and see if there's any other tools he can use on it. I'll tell him to check the clearance from retainer to guide.

I agree with the spring damper looking funny and out of shape. Can you take a picture of a few more for comparison? Either way, that one is not right.

nm9stheham

Well-Known Member

And dang.. I just looked at the lower portion of that damper coil.... it is all out of whack. I am pretty sure that damper is broken in the middle.I agree with the spring damper looking funny and out of shape. Can you take a picture of a few more for comparison? Either way, that one is not right.

And dang.. I just looked at the lower portion of that damper coil.... it is all out of whack. I am pretty sure that damper is broken in the middle.

Wow ! Good Observations

I just blew up the photo of the Damper Spring up to Full Screen on my computer. Sure enough that Damper part of the Dual Spring is broke in the middle (probably on the back side of the photo where we can't actually see the actual break). You can follow the Planes of the Spring Curls and the fop half does not run in line with the bottom half. In fact it looks as though the top half is wedging itself into the bottom half binding everything up.

Well this could surely bend the push rod if that dual spring Damper is broke in half and all bound up ! Not being able to open the valve all the way, and making it real Difficult for the OP to take the keepers off that valve with his spring compressor because it won't compress.

You guys are onto something here, it is all fitting together now as to what is wrong.

PRH

Well-Known Member

I can’t tell if the damper is broken or not by looking at the pic, but I can tell you I’ve seen piles of springs through the years where the dampers fit between the coils poorly, and/or aren’t long enough to reach from the retainer to the head.

Not ideal by any means....... but it rarely causes any problems.

Take the springs off, take them apart...... see what to find.

This is the style of spring compressor you need:

Not ideal by any means....... but it rarely causes any problems.

Take the springs off, take them apart...... see what to find.

This is the style of spring compressor you need:

Last edited:

Wyrmrider

Well-Known Member

does he not still have the heads on?

Dodge72

Odd one out

We'll have to take a look at the springs tomorrow or Friday, I'll take some more pictures as well. Yes the head is currently still off.

We'll have to take a look at the springs tomorrow or Friday, I'll take some more pictures as well. Yes the head is currently still off.

Was just thinking here this morning. You were saying that you could not compress the valve springs with the valve spring compressor tool to get the valve keepers out.

I usually just take a 6" long 2 x 2 piece of wood and give each valve spring retainer a whack with the wood and a hammer. This breaks them loose so you can use the valve spring compressor tool more easily.

Things get "Set and Stick" with the valve retainer, valve keepers, and the end of the valves after sitting under spring pressure for a long time, making it difficult to press them down with the valve spring compressor.

PRH

Well-Known Member

It sounded to me like he was using this style of spring compressor, which doesn’t compress the inner spring.

-

Similar threads

- Replies

- 42

- Views

- 23K