You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleanup turns to mess up. Need some help troubleshooting.

- Thread starter SwingerLSX75

- Start date

-

SwingerLSX75

Well-Known Member

SwingerLSX75

Well-Known Member

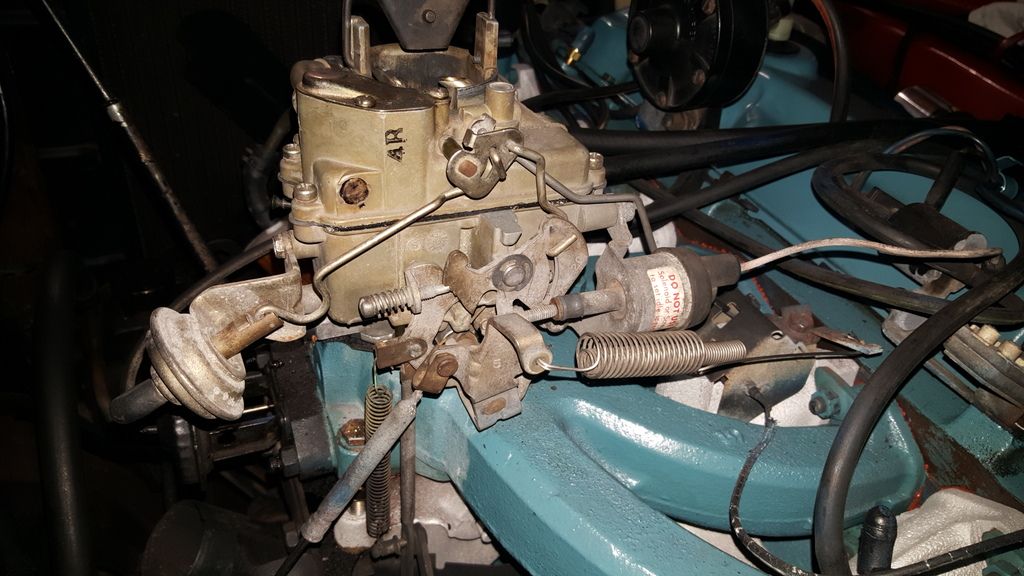

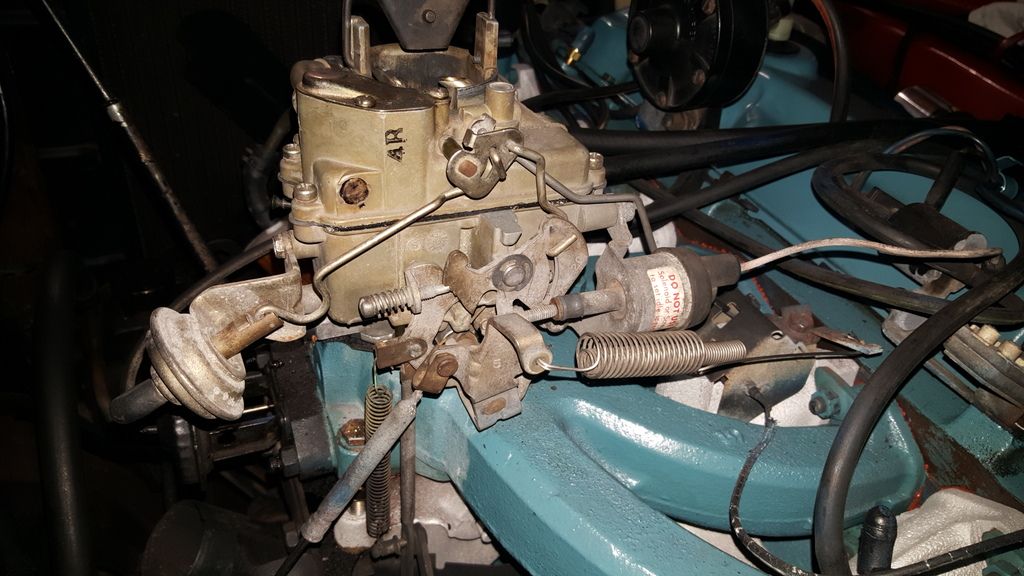

Well guys I thought I had this thing squared away but this holley 1945 has come calling for attention again.

Well ive rebuilt this carb, she fired right back up afterwards but still seem to be having issues. Ive been running through all the adjustment procedures in the manual. All the ones It says to do after refurb too. Its running better but it randomly cut off in the drive way. I do have a question and I will be posting pictures up tomorrow.

At any point in time is the choke cam just supposed to swing freely? Whenever I first fire it up, It runs fine and the fast idle screw is sitting on the second notch of the choke cam just like the book says. But once it warms up the choke valve in the top of the carb seems to just sit wide open and there is no tension on the choke lever, this just leads to the cam basically spinning around freely and now being in any set position or locked in anywhere. Ill post a short video tomorrow so you can see. But any help is appreciated.

Well ive rebuilt this carb, she fired right back up afterwards but still seem to be having issues. Ive been running through all the adjustment procedures in the manual. All the ones It says to do after refurb too. Its running better but it randomly cut off in the drive way. I do have a question and I will be posting pictures up tomorrow.

At any point in time is the choke cam just supposed to swing freely? Whenever I first fire it up, It runs fine and the fast idle screw is sitting on the second notch of the choke cam just like the book says. But once it warms up the choke valve in the top of the carb seems to just sit wide open and there is no tension on the choke lever, this just leads to the cam basically spinning around freely and now being in any set position or locked in anywhere. Ill post a short video tomorrow so you can see. But any help is appreciated.

nm9stheham

Well-Known Member

As I recall without looking, the air flow past the choke butterfly, and its shape, with the weigth centered below the shaft, should keep it open.

When this random cuts off , does it sputter and gradually die, or does it cut off like a light switch? The latter is a characteristic of ignition problems, not carb/fuel.

A new thread would be nice....

When this random cuts off , does it sputter and gradually die, or does it cut off like a light switch? The latter is a characteristic of ignition problems, not carb/fuel.

A new thread would be nice....

SwingerLSX75

Well-Known Member

It will start and idle just fine. I let it run, I drove It around the neighborhood, and then as I let it idle in the driveway it cutoff like a light switch. But after its done warming up the choke cam just seems to rock back off the fast idle screw.

nm9stheham

Well-Known Member

Off like a light switch points to the ignition system. Do you have a voltmeter available?

SwingerLSX75

Well-Known Member

I have a voltmeter in the garage. I ran it just a few minutes ago and took a before picture of the position of the choke cam. Now once the car warms up the cam rotates about 90 degrees clockwise and has a lot of "play" to where it can be bounced back and forth. Is that normal when the car warms up?

But I also noticed out of the corner of my eye that right as it died I saw the plunger on the choke diaphragm popped out and it shut down right after.

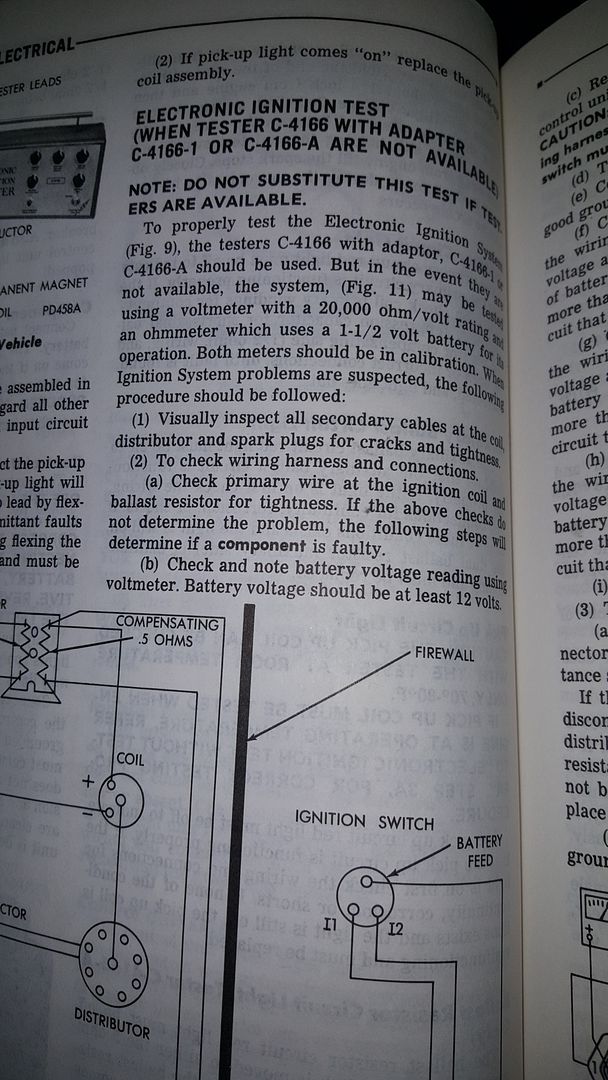

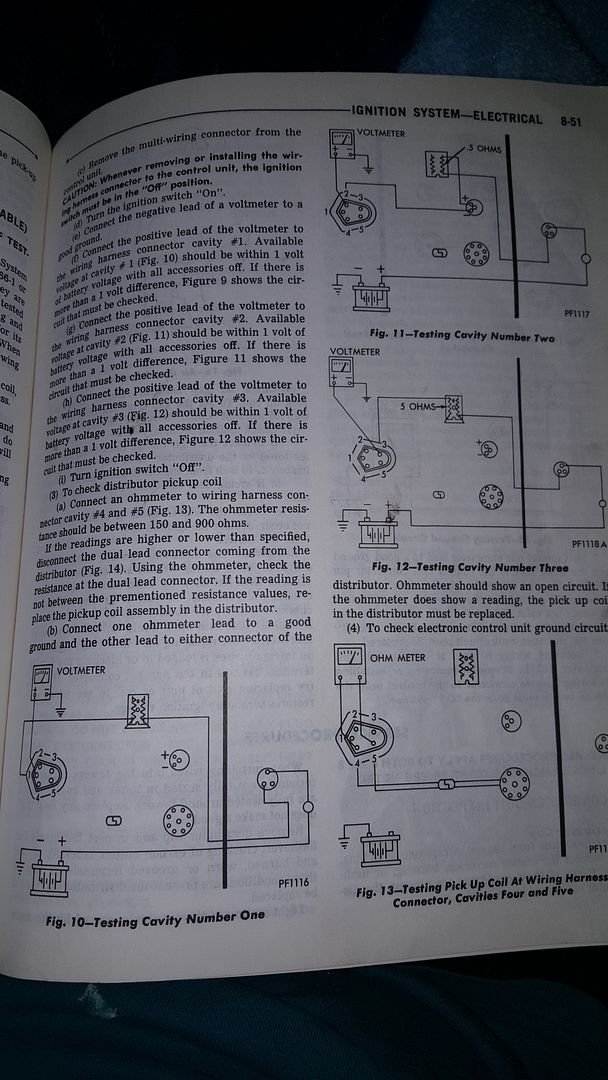

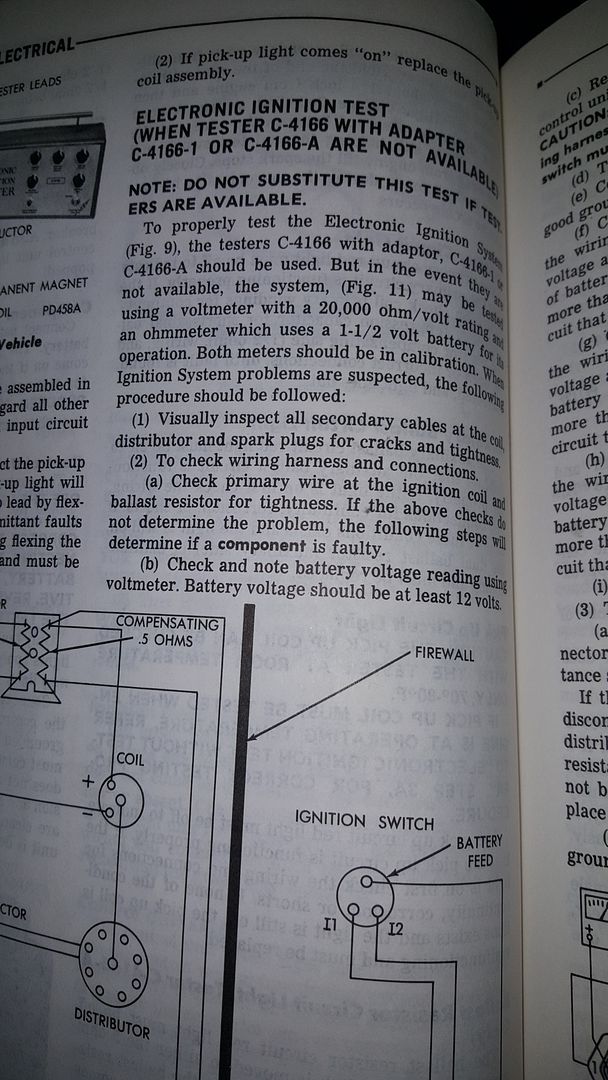

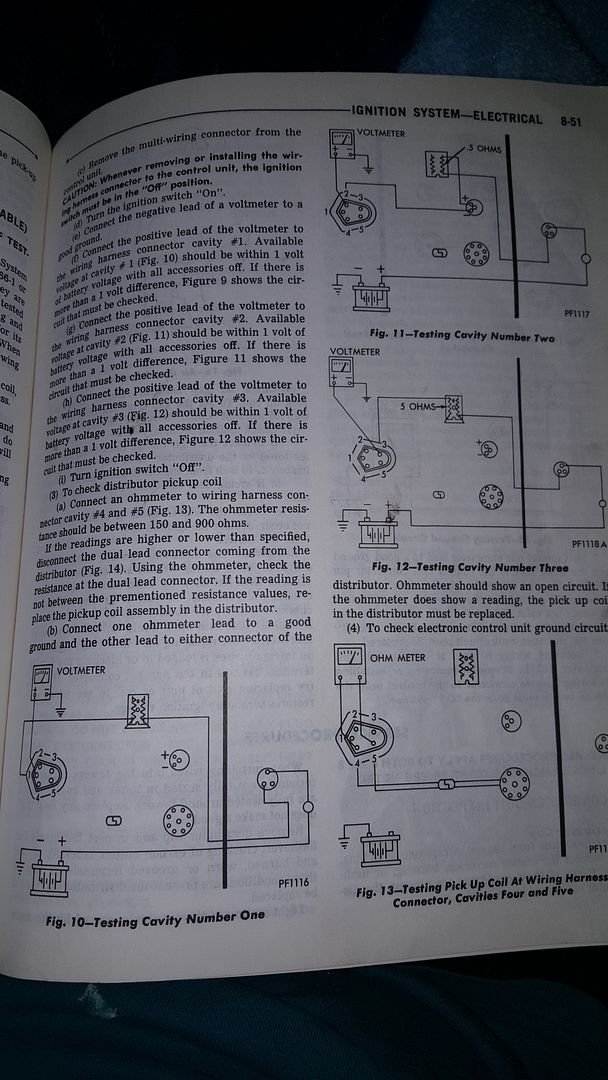

The multimeter tests your talking about are the ones on page 8-50 through 8-52 of the manual?

But I also noticed out of the corner of my eye that right as it died I saw the plunger on the choke diaphragm popped out and it shut down right after.

The multimeter tests your talking about are the ones on page 8-50 through 8-52 of the manual?

nm9stheham

Well-Known Member

The choke diaphragm you see is the choke pull-off, used to open the choke a slight amount after the engine starts and prevent it form being over-choked. It uses engine vacuum to do this. If the engine dies, and the vacuum goes away, then the choke-pull off will move out; I'm not sure if it will pop out or just gradually move out. But, the question is if the engine dieing is due to the vacuum going away suddenly, or the vacuum goes away due to the engine dieing. You can test by sucking a vacuum on the hose to the pull-off by mouth and see if the diaphragm is not leaking and it moves in and out with vacuum.

Not sure what FSM section you refer to; your FSM is quite different from my '62! Section 8 was for engines in 1962....

Put your voltmeter on the blue lead to the ballast and see if that is a steady 12 volts or close to that. Then check all the ignition system connections from distributor to ECU to ballast. Getting late here....

Not sure what FSM section you refer to; your FSM is quite different from my '62! Section 8 was for engines in 1962....

Put your voltmeter on the blue lead to the ballast and see if that is a steady 12 volts or close to that. Then check all the ignition system connections from distributor to ECU to ballast. Getting late here....

SwingerLSX75

Well-Known Member

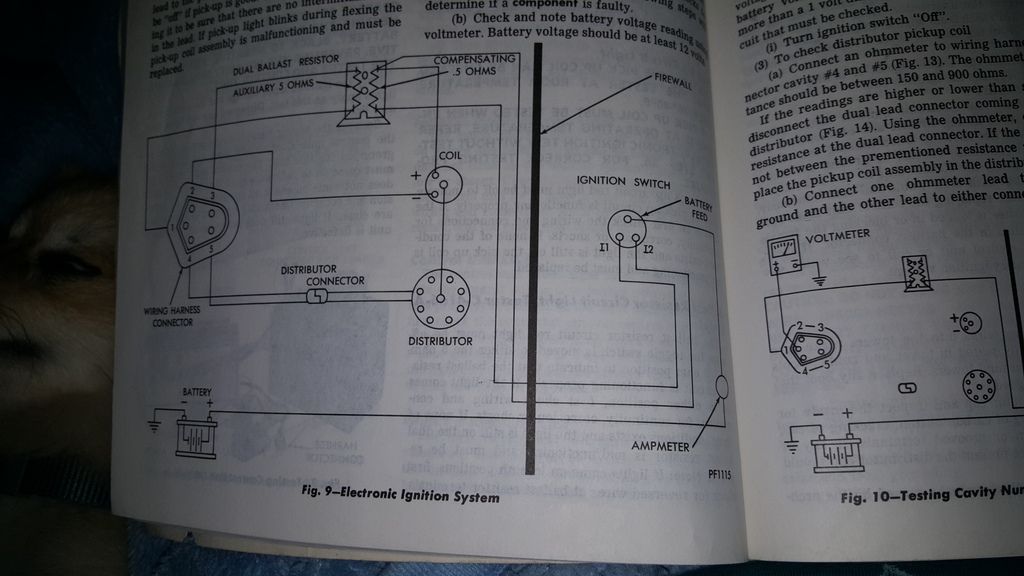

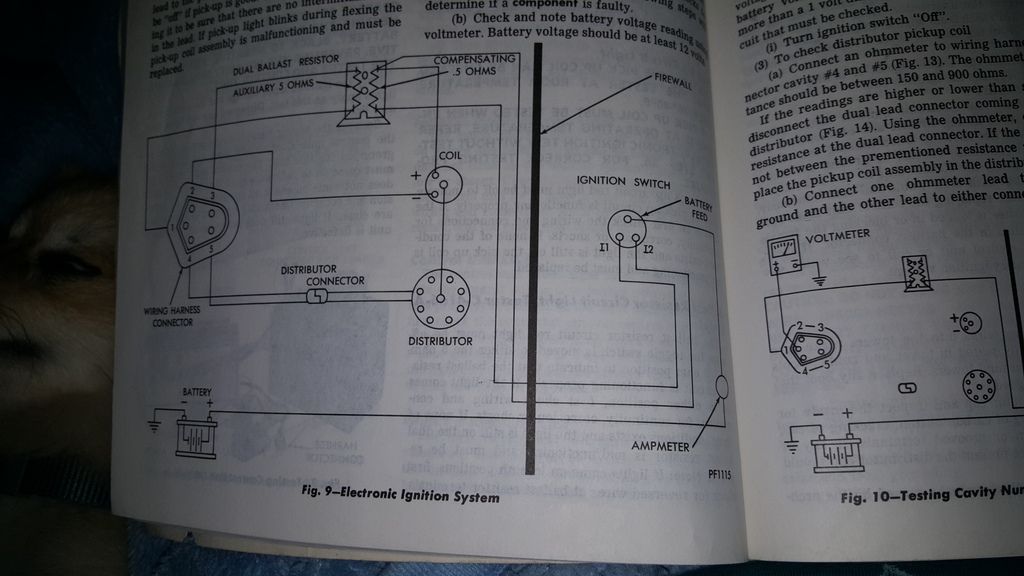

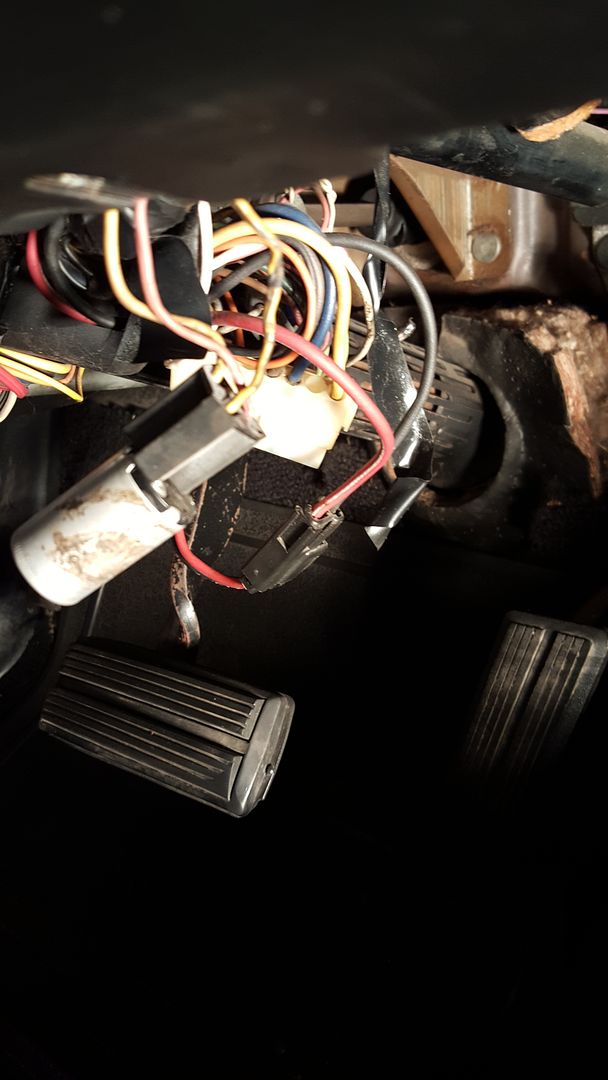

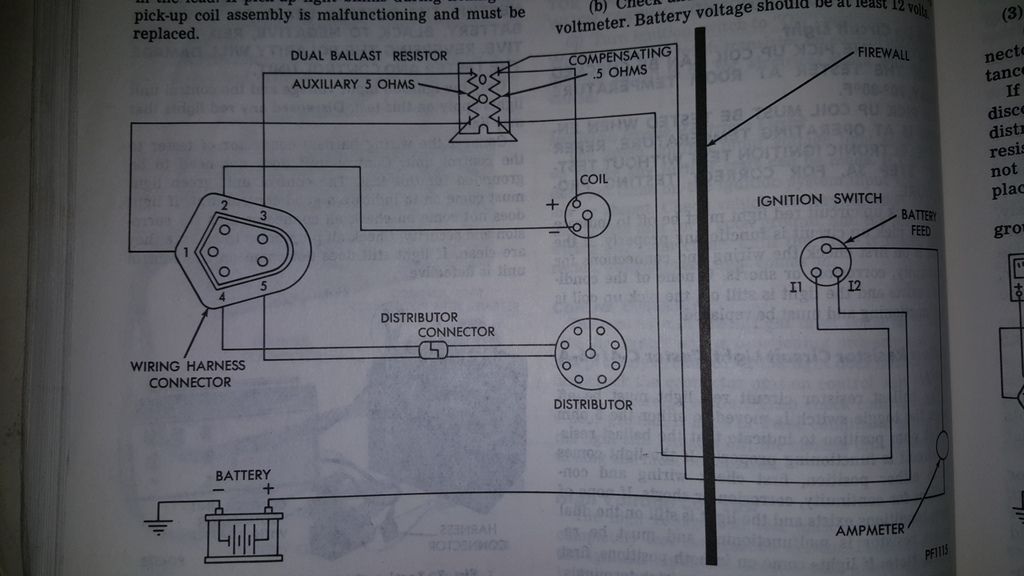

Here is the section im talking about. it refers to testing the voltage at the connector to the ECM with the ignition in the on position. It states that the voltage at test points 1,2,3 should be within 1 volt of the battery voltage. However with 12v on the battery im only showing 10.3 volts here. It shows each diagram to test the circuit to figure out where the issue is.

SwingerLSX75

Well-Known Member

Well I made sure the battery was charged up and now she doesn't even want to run and idle. She's back to just spinning and spinning again.

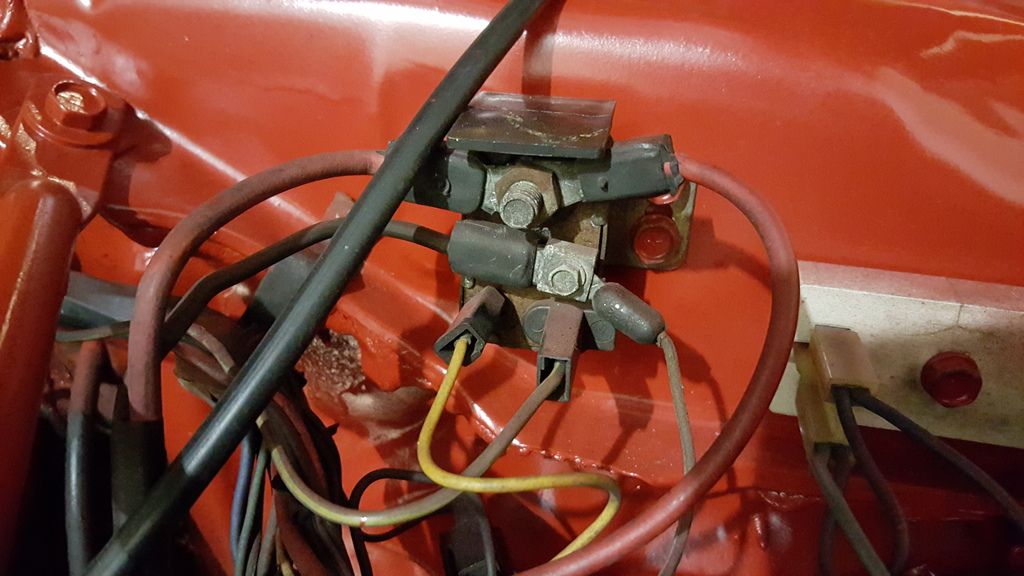

But I broke out the multimeter and tested the two blue leads on the left side of the ballast resistor a few minutes ago. With the key in the ignition and it turned to on(right before I turn to crank it over) it reads 9.4 volts on the bottom and 3.3 on the top.

But I broke out the multimeter and tested the two blue leads on the left side of the ballast resistor a few minutes ago. With the key in the ignition and it turned to on(right before I turn to crank it over) it reads 9.4 volts on the bottom and 3.3 on the top.

TylerW

Well-Known Member

Check for spark. Pull a plug, reattach the plug wire and lay the plug where you can observe it and where it is resting on a bare metal surface. Spin the engine over and see whether the plugs are firing.

If not 99% of the time the ECU box has failed. Always keep a spare one on hand.

If not 99% of the time the ECU box has failed. Always keep a spare one on hand.

SwingerLSX75

Well-Known Member

Well this is like the 3rd time I've run into this issue. Pulling the carb and reworking it has been the fix the last couple times, but I just rebuilt the carb so im going to disconnect the fuel line and test for spark again and go from there. Tired of messing with this thing already. I've been troubleshooting/fixing things nonstop for the last couple weeks.

TylerW

Well-Known Member

I feel your pain. I had an ECU crap out in the middle of an intersection.

Just remember that an engine needs fuel, air and spark, in the right amounts at the right time. So, to troubleshoot stuff like this, first just determine what it HAS...then that'll easily show you what it doesn't have.

1. Check for spark. Either you can use the way I talked about or you can use an inline spark tester that you buy at the parts store. On these cars you can spin the engine under the hood by using a screwdriver to jump the starter relay. Just make sure to have the key on.

2. Don't obsess over the ballast resistor. That thing simply gives you two different voltages: near battery voltage used in the start position to get the car running, and a reduced RESISTED running voltage when the switch is in the ON position. That is to protect the coil by feeding it reduced voltage.

They nearly always fail in the RUN side because that's where they do all their work and generate heat. When the run side fails you have spark and the engine runs as long as the key is held over to START. Once let off back to run, the voltage dies, the engine dies and owner pulls hair out. But..once you've had one fail you know the symptoms.

3. If you have spark at all times maybe the carb is at fault or something in the fuel system. But, those carbs are pretty reliable, more so than the 1920.

4. You can build an HEI ignition for these easily that eliminates the ballast and the coil and their associated problems. You don't have to remove them or alter the wiring so everything can be returned to stock.

Just remember that an engine needs fuel, air and spark, in the right amounts at the right time. So, to troubleshoot stuff like this, first just determine what it HAS...then that'll easily show you what it doesn't have.

1. Check for spark. Either you can use the way I talked about or you can use an inline spark tester that you buy at the parts store. On these cars you can spin the engine under the hood by using a screwdriver to jump the starter relay. Just make sure to have the key on.

2. Don't obsess over the ballast resistor. That thing simply gives you two different voltages: near battery voltage used in the start position to get the car running, and a reduced RESISTED running voltage when the switch is in the ON position. That is to protect the coil by feeding it reduced voltage.

They nearly always fail in the RUN side because that's where they do all their work and generate heat. When the run side fails you have spark and the engine runs as long as the key is held over to START. Once let off back to run, the voltage dies, the engine dies and owner pulls hair out. But..once you've had one fail you know the symptoms.

3. If you have spark at all times maybe the carb is at fault or something in the fuel system. But, those carbs are pretty reliable, more so than the 1920.

4. You can build an HEI ignition for these easily that eliminates the ballast and the coil and their associated problems. You don't have to remove them or alter the wiring so everything can be returned to stock.

SwingerLSX75

Well-Known Member

I know it takes fuel, spark and compression to run. I've run through that same cycle with this thing 3 times already and its ended up being an issue with the carb each time. The compression was 120-125 across all 6 cylinders a week ago when I tested it and I had spark then. So I will verify again tomorrow morning before I look at fuel once again.

Weird thing I noticed since it has a new fuel pump on there, is that since it waqs installed my clear fuel filter is completely full of fuel all the time rather than half or 3/4 like the old fuel pump. When it had the old fuel pump(that was leaking) I never had issues with the fuel on the car and it always fired right up. But now it keeps having fuel problems.

Weird thing I noticed since it has a new fuel pump on there, is that since it waqs installed my clear fuel filter is completely full of fuel all the time rather than half or 3/4 like the old fuel pump. When it had the old fuel pump(that was leaking) I never had issues with the fuel on the car and it always fired right up. But now it keeps having fuel problems.

nm9stheham

Well-Known Member

You provided a good data point for this issue: 9.4 volts to the 2 blue wires on the ballast, with the ignition switch in RUN (not cranking), is too low; it should be no more than 1/2 volt below the battery voltage. Get out the wiring diagram and start to trace from that point back to the ignition switch with the switch in RUN, and then back to the battery; you have excessive voltage drop somewhere. That needs to be fixed as you have a bad connection or wire or ignition switch.

BTW, in your last pix, the ballast has a crack in it. Replace it as it could be causing the 'off like a light switch' symptoms; that's not obsessing! LOL

BTW, in your last pix, the ballast has a crack in it. Replace it as it could be causing the 'off like a light switch' symptoms; that's not obsessing! LOL

SwingerLSX75

Well-Known Member

You provided a good data point for this issue: 9.4 volts to the 2 blue wires on the ballast, with the ignition switch in RUN (not cranking), is too low; it should be no more than 1/2 volt below the battery voltage. Get out the wiring diagram and start to trace from that point back to the ignition switch with the switch in RUN, and then back to the battery; you have excessive voltage drop somewhere. That needs to be fixed as you have a bad connection or wire or ignition switch.

BTW, in your last pix, the ballast has a crack in it. Replace it as it could be causing the 'off like a light switch' symptoms; that's not obsessing! LOL

I broke out my meter last night and tested all the wires except for the ignition switch in terms of resistance and everything tested out fine. The two wire connector to the distributor for the ECU that is supposed to be between 150 and 900 ohms came in at 279 ohms. So that tested out good.

With the battery at 12.0 volts the two leads on the ballast resistor tested at 10.1 volts with the ignition in the "on" position. SO I have to figure out why I'm dropping 2 volts when I have a spare ballast resistor in the trunk that I can throw in the car to get rid of that cracked one so no worries there. What is the easiest way to get to the ignition switch for testing?

nm9stheham

Well-Known Member

You gotta go into the steering column and get to all the connections.....no easy way that I know of!

I have to wonder if that cracked ballast was the cause of the sudden cut outs... it would if the crack extended into the resistance wire inside.

As a test, you can temporarily jumper a wire from the large lug on the starter relay to the blue wires to the ballast and see how that improves things. But ultimately you need to fix the voltage drop; it won't get better and it will effect charging system regulation too.

I have to wonder if that cracked ballast was the cause of the sudden cut outs... it would if the crack extended into the resistance wire inside.

As a test, you can temporarily jumper a wire from the large lug on the starter relay to the blue wires to the ballast and see how that improves things. But ultimately you need to fix the voltage drop; it won't get better and it will effect charging system regulation too.

sccachallenger

Well-Known Member

You gotta go into the steering column and get to all the connections.....no easy way that I know of!

I have to wonder if that cracked ballast was the cause of the sudden cut outs... it would if the crack extended into the resistance wire inside.

As a test, you can temporarily jumper a wire from the large lug on the starter relay to the blue wires to the ballast and see how that improves things. But ultimately you need to fix the voltage drop; it won't get better and it will effect charging system regulation too.

Yes! do this next, if it runs you'll have more enthusiasm for finding/fixing the problem.

Also, jumping the starter relay with key in the run position can help you diagnose a bad ballast.

SwingerLSX75

Well-Known Member

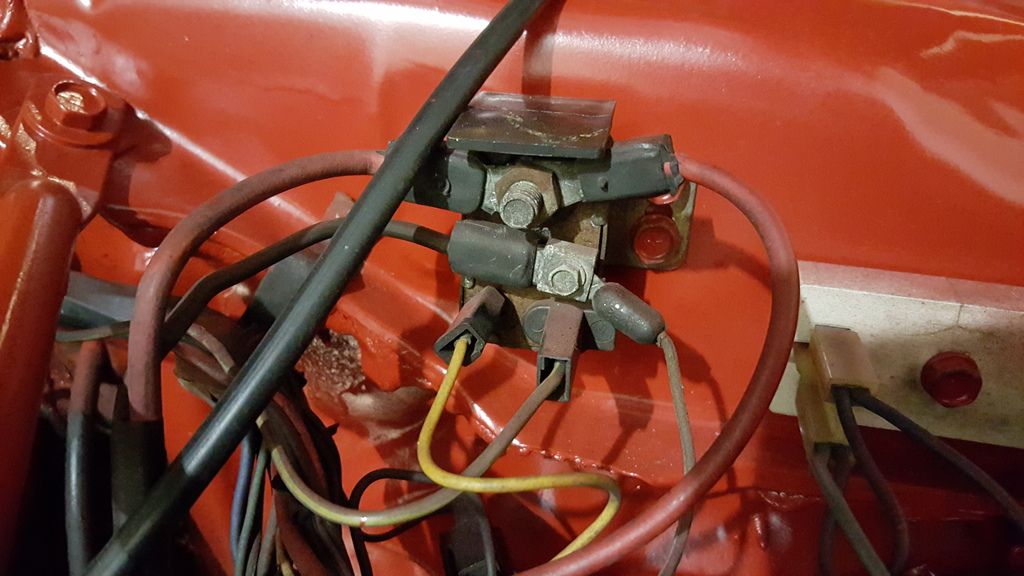

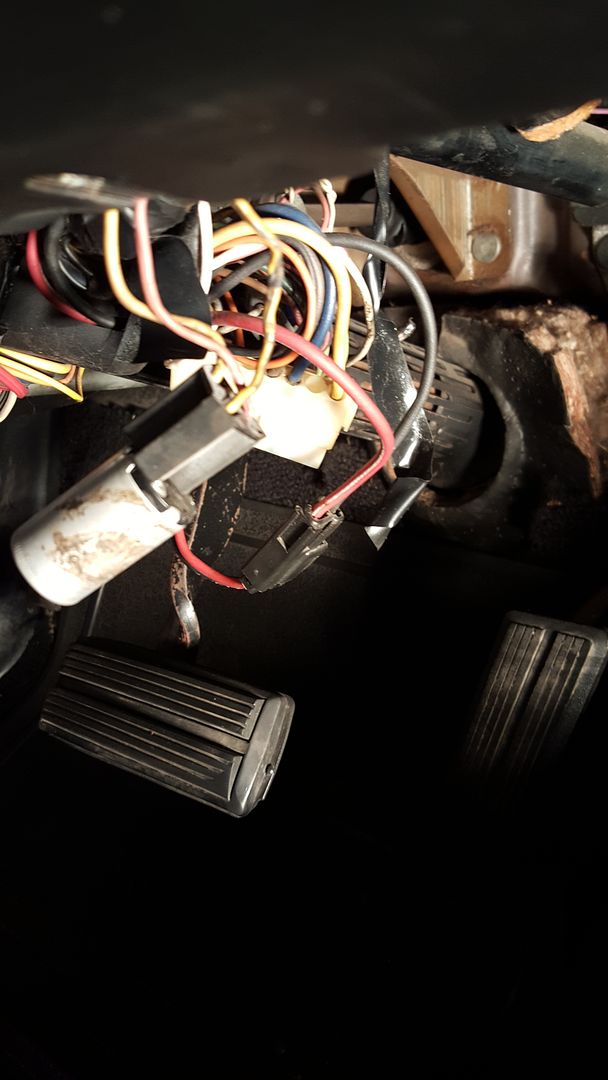

Ok so here is where I am with tracing out this inconsistency with voltage through the ignition system.

I measured the red wire that comes from the battery to the ignition switch and its at 13V leading to the switch(dead center of the picture accompanied by one black wire in the connector).

The diagram version is pictured below and shows it coming from the battery through the firewall to the ignition switch on the right side of the page.

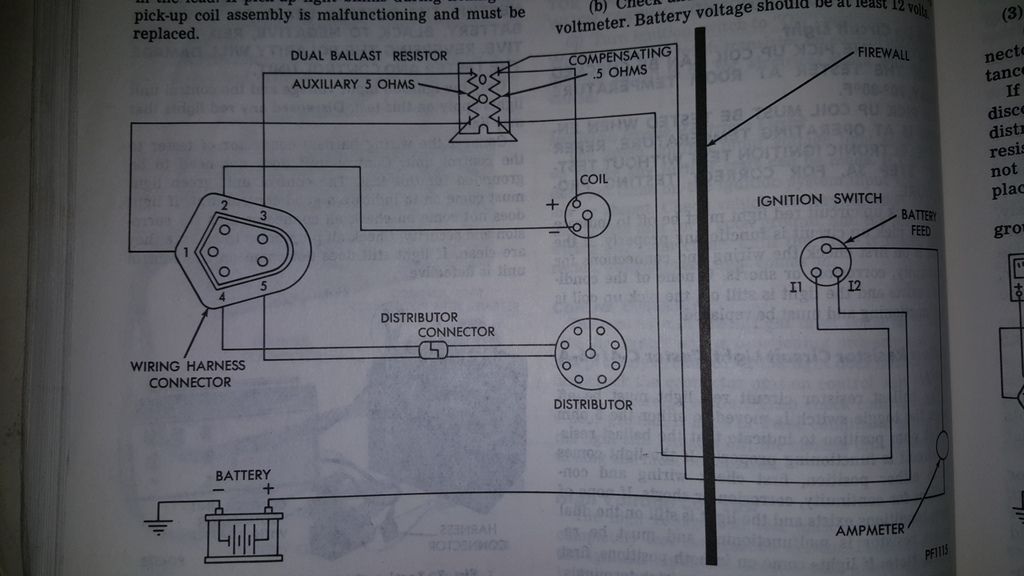

However once that 13v hits the ignition switch and begins its travels to the ballast the voltage starts to drop. The larger yellow connector centered in the picture above is where the dark blue wire carrying the voltage to the ballast makes a connection before running the last 12 inches or so into the firewall. The blue wire on the switch side leading into the connector reads 12.2V, as soon as it goes through that connector it drops to 10.5V and stays at 10.5 until it reaches the ballast. Ive measured it going into the firewall and coming out of the firewall as well as going into the ballast resistors and they all are same at 10.5V with the ignition in the on position. How would it going the ignition switch magically make it drop 2.5V on the way to the ballast? Also the silver capacitor with the yellow and pink wires in the middle left of the picture(closest to the camera) stays hot the entire time, is that normal?

I measured the red wire that comes from the battery to the ignition switch and its at 13V leading to the switch(dead center of the picture accompanied by one black wire in the connector).

The diagram version is pictured below and shows it coming from the battery through the firewall to the ignition switch on the right side of the page.

However once that 13v hits the ignition switch and begins its travels to the ballast the voltage starts to drop. The larger yellow connector centered in the picture above is where the dark blue wire carrying the voltage to the ballast makes a connection before running the last 12 inches or so into the firewall. The blue wire on the switch side leading into the connector reads 12.2V, as soon as it goes through that connector it drops to 10.5V and stays at 10.5 until it reaches the ballast. Ive measured it going into the firewall and coming out of the firewall as well as going into the ballast resistors and they all are same at 10.5V with the ignition in the on position. How would it going the ignition switch magically make it drop 2.5V on the way to the ballast? Also the silver capacitor with the yellow and pink wires in the middle left of the picture(closest to the camera) stays hot the entire time, is that normal?

nm9stheham

Well-Known Member

The firewall contacts are commonly corroded and so the drop there is not at all unusual. So, find some Packard 56 terminals and a good crimper for them; resist the temptation to just kluge in something. You probably have others in the same condition that need replacing. The ones carrying the alternator current into the dash area and also making the connection for the power to come in are very susceptible to burning up, as these carry by far the highest currents. The MAD bypass you may have rad about is all about bypassing those.

For some of the firewall contacts that are not corroded, a good cleaning will help. Apply some dielectric grease around the contacts when you are done and ready to assemble it.

As for the drop in the ignition switch, the current flowing through the blue wire is causing the voltage drop in the IGN1 position of the ignition switch. Basically, the plating is worn off of the ignition switch contacts internally, and there is resistance built up there. So, you should also go ahead and replace the ignition switch for sure. That is one likely culprit in the cut-out issue; a worn out switch is common. Easy to get at NAPA.

All the above is a 'pay me now or pay me later' proposition. So ignoring it is not a good idea.

As for the small can, based on the pink and yellow wire colors, look for an 'accessory connector and time delay' block on your FSM schematic. It think it is a relay for putting power onto things like...well actually I don't know what things! Look on the label to see if it says 'relay' anywhere. If it is, then it will be warm whenever the relay is active.

For some of the firewall contacts that are not corroded, a good cleaning will help. Apply some dielectric grease around the contacts when you are done and ready to assemble it.

As for the drop in the ignition switch, the current flowing through the blue wire is causing the voltage drop in the IGN1 position of the ignition switch. Basically, the plating is worn off of the ignition switch contacts internally, and there is resistance built up there. So, you should also go ahead and replace the ignition switch for sure. That is one likely culprit in the cut-out issue; a worn out switch is common. Easy to get at NAPA.

All the above is a 'pay me now or pay me later' proposition. So ignoring it is not a good idea.

As for the small can, based on the pink and yellow wire colors, look for an 'accessory connector and time delay' block on your FSM schematic. It think it is a relay for putting power onto things like...well actually I don't know what things! Look on the label to see if it says 'relay' anywhere. If it is, then it will be warm whenever the relay is active.

SwingerLSX75

Well-Known Member

The firewall contacts are commonly corroded and so the drop there is not at all unusual. So, find some Packard 56 terminals and a good crimper for them; resist the temptation to just kluge in something. You probably have others in the same condition that need replacing. The ones carrying the alternator current into the dash area and also making the connection for the power to come in are very susceptible to burning up, as these carry by far the highest currents. The MAD bypass you may have rad about is all about bypassing those.

For some of the firewall contacts that are not corroded, a good cleaning will help. Apply some dielectric grease around the contacts when you are done and ready to assemble it.

As for the drop in the ignition switch, the current flowing through the blue wire is causing the voltage drop in the IGN1 position of the ignition switch. Basically, the plating is worn off of the ignition switch contacts internally, and there is resistance built up there. So, you should also go ahead and replace the ignition switch for sure. That is one likely culprit in the cut-out issue; a worn out switch is common. Easy to get at NAPA.

All the above is a 'pay me now or pay me later' proposition. So ignoring it is not a good idea.

As for the small can, based on the pink and yellow wire colors, look for an 'accessory connector and time delay' block on your FSM schematic. It think it is a relay for putting power onto things like...well actually I don't know what things! Look on the label to see if it says 'relay' anywhere. If it is, then it will be warm whenever the relay is active.

The drop im seeing isn't at the firewall its at the connector right under the steering column. I'm going to try and clean that thing up today because it is literally dropping a volt and a half once that connector is connected(12.2 by itself and 10.5 after its connected). I will be looking at everything else on that connector to see if maybe something else may be causing the drop but it just doesn't seem normal to me to drop 1.5 volts at a connection.

I do have a question though. What is the standard reading at the coil with the ignition in the on position? I'm getting right at 4.8volts at the positive connection on the coil.

nm9stheham

Well-Known Member

What is going on is there is no current through the IGN1 position of the ignition switch when nothing is connected. So there will be no drop at that contact or its connectors and the drop to 12.2 volts inside the ignition switch is due to other drops. Once you make the connection, then the current draw on that line causes added voltage drop in the IGN1 contact inside the switch and that shows up in the lower voltage. In fact the extra current will cause added voltage drop at ANY poor contact or connections between the battery and that point. This is because voltage drop in wires, switches, connections, etc., usually ONLY occurs when there is current flow. If you want to isolate the drop location precisely, keep the connection connected. BTW, it may be tempting to not replace the ignition switch, but IMHO you are just causing more extended pain for yourself....each connection and wire and switch contact from the battery to the coil+ is a suspect until proven otherwise.The drop im seeing isn't at the firewall its at the connector right under the steering column. I'm going to try and clean that thing up today because it is literally dropping a volt and a half once that connector is connected(12.2 by itself and 10.5 after its connected). I will be looking at everything else on that connector to see if maybe something else may be causing the drop but it just doesn't seem normal to me to drop 1.5 volts at a connection.

I do have a question though. What is the standard reading at the coil with the ignition in the on position? I'm getting right at 4.8volts at the positive connection on the coil.

Standard reading at the coil + is 8-9-10 volts cold and lowers to 5-6-7 volts when the ballast warms up (takes 20-30 seconds), assuming the correct ballast value/type is being used.

SwingerLSX75

Well-Known Member

Gotcha, im only getting 4.8 regardless of the time I check it. It has 6.6V at the ballast that feeds the coil. So its just a constant drop in voltage through the system the further it gets away from the ignition. It hasn't run in a week or so and that's the reading its giving me at the coil.

Ordered a new switch so ill replace that and then see if it changes. Till then all I can do is wait.

Ordered a new switch so ill replace that and then see if it changes. Till then all I can do is wait.

SwingerLSX75

Well-Known Member

Well after doing the testing and narrowing it down to the ignition switch I began tearing the steering column apart to replace the switch. Using the how-to in the ignition section of this forum was extremely helpful. I recommend giving it a look see if you need some help or advice on how to replace yours. Should have an update later this afternoon.

UPDATE:

Well after I finished the install of the new ignition switch I have about half a volt more power to the coil, and currently im not getting any spark to any of the spark plugs. I checked all the wires(which were brand new 3 months ago) and the cap and rotor(new 3 months ago) and none showed signs of problems. I checked the air gap in the distributor and it was off a little so I adjusted it and I even swapped in another coil and still have no spark. So now I'm looking at pulling the distributor to give the whole thing a lookover and maybe trying to figure out what else could be causing only 5.1V making it to the coil. If nothing is found there I'm about done messing with this slant and will just count her as hibernating until I do this 5.7L hemi swap

UPDATE:

Well after I finished the install of the new ignition switch I have about half a volt more power to the coil, and currently im not getting any spark to any of the spark plugs. I checked all the wires(which were brand new 3 months ago) and the cap and rotor(new 3 months ago) and none showed signs of problems. I checked the air gap in the distributor and it was off a little so I adjusted it and I even swapped in another coil and still have no spark. So now I'm looking at pulling the distributor to give the whole thing a lookover and maybe trying to figure out what else could be causing only 5.1V making it to the coil. If nothing is found there I'm about done messing with this slant and will just count her as hibernating until I do this 5.7L hemi swap

nm9stheham

Well-Known Member

Ummmm, you need to fix this issue because it will plague you with any engine. Exactltry hwere are you measuring the 5.1V? At the coil +?

Set the spark wire from the coil so that the end is 1/4" from metal. Use a jumper to ground the coil - while the key is in ON and then unground the jumper from the coil -. You should get a spark. (DON'T be holding the metal of the jumper wire when you do this!). This test will check the coil. If that sparks thenm the problem is in the ECU or distributor pickup. BTW, did you set the pickup gap with a non-magnetic feeler? Not steel...

Set the spark wire from the coil so that the end is 1/4" from metal. Use a jumper to ground the coil - while the key is in ON and then unground the jumper from the coil -. You should get a spark. (DON'T be holding the metal of the jumper wire when you do this!). This test will check the coil. If that sparks thenm the problem is in the ECU or distributor pickup. BTW, did you set the pickup gap with a non-magnetic feeler? Not steel...

-

Similar threads

- Replies

- 5

- Views

- 765

- Replies

- 25

- Views

- 2K