I have always been told to store cranks sitting on end and heads ,.... I always s tored heads lying flat. just wondering if anyone knows or does it make any difference?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

correct way to store cranks and heads

- Thread starter barbee6043

- Start date

-

340doc

Well-Known Member

When I worked at a machine shop we had a rig bolted to the wall that held cranks upright for storage I usually store heads on the intake side. I'm sure others will comment.

Cranks standing upright, heads block side if room(intake side for saving space). Blocks on bell housing face. Do not clean. Grease machined surfaces. Bag in heavy trash bags. Not going to fight anyone, just the way I've always done it. No problems.

that's what I have always done. only thing I am considered is making a "double rail" where I would hang them from flywheel end. ????? .......Cranks standing upright, heads block side if room(intake side for saving space). Blocks on bell housing face. Do not clean. Grease machined surfaces. Bag in heavy trash bags. Not going to fight anyone, just the way I've always done it. No problems.

http://www.crcindustries.com/ei/product_detail.aspx?id=02061

Sprayed with this, wrapped in plastic and stood on end.

Sprayed with this, wrapped in plastic and stood on end.

Old timers always told me, (including my Dad) to stand them on end, cranks and heads, to avoid warping. Fact or fiction?

When you buy a crank kit from an auto parts store, they are not stacked on end in boxes. They are stored on shelves, laying flat on their side. Same as new cranks from any dealership, vendor like Summit, Jegs and everybody else.

If it was true that it warped them, you'd have a slew of people with bent cranks and warped heads. That ain't the case, so it's an old wive's tale if ever there was.

If it was true that it warped them, you'd have a slew of people with bent cranks and warped heads. That ain't the case, so it's an old wive's tale if ever there was.

I alway stored crankshaft on spare blocks in the saddle so to speak...lubed up with vaseline...........

Of course that stuff is expensive when you try to purchase it by itself at the drug store cause you got to buy a comb,some bubble gum,beer and cigarettes....You know not too look weird.......................................................................Heads I just lube up and put on the shelf flat down and put a valve cover over it then a fender cover.

Of course that stuff is expensive when you try to purchase it by itself at the drug store cause you got to buy a comb,some bubble gum,beer and cigarettes....You know not too look weird.......................................................................Heads I just lube up and put on the shelf flat down and put a valve cover over it then a fender cover.

Works for me. Like RRR posted, I'll not argue about cranks, just how I've always done it. They take up less room also standing or hung up.that's what I have always done. only thing I am considered is making a "double rail" where I would hang them from flywheel end. ????? .......

pishta

I know I'm right....

stand 'em up, thy take less space but put a leash on them so they dont tip over. As for cranks drooping over time, I dont think so Tim. Now talk about a prop shaft on a Battleship that is unsupported for tens of feet. Sure, go ahead and turn it bi-annually. If your worried about a stored crank being tweaked, just torque it in a block with bearings for a week, itll come clear. I doused some fresh heads with penetrating oil (not WD-40, it was Telco stuff) 6 months and those are still as bright as the day off the fly cutter. The good corrosion control stuff will go on like wax, sticking good.

nm9stheham

Well-Known Member

If cranks 'drooped' lying on their sides, then they would droop even worse hung from a rack on one counterweight. Letting them fall over or drop is the problem!

seabee

Well-Known Member

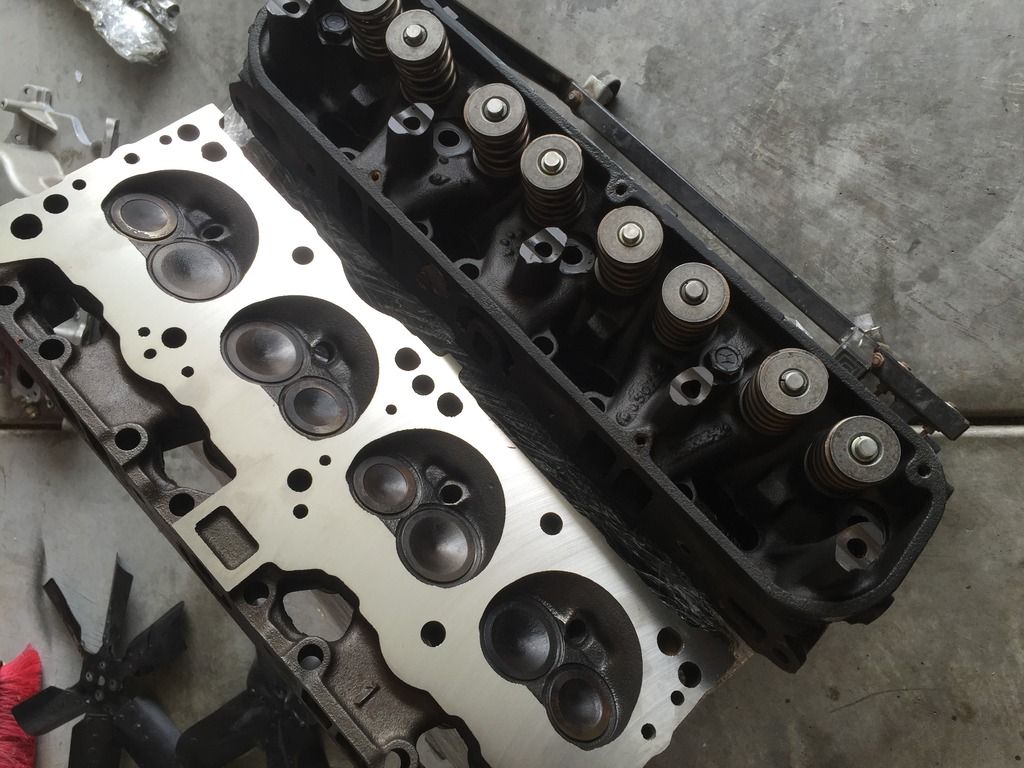

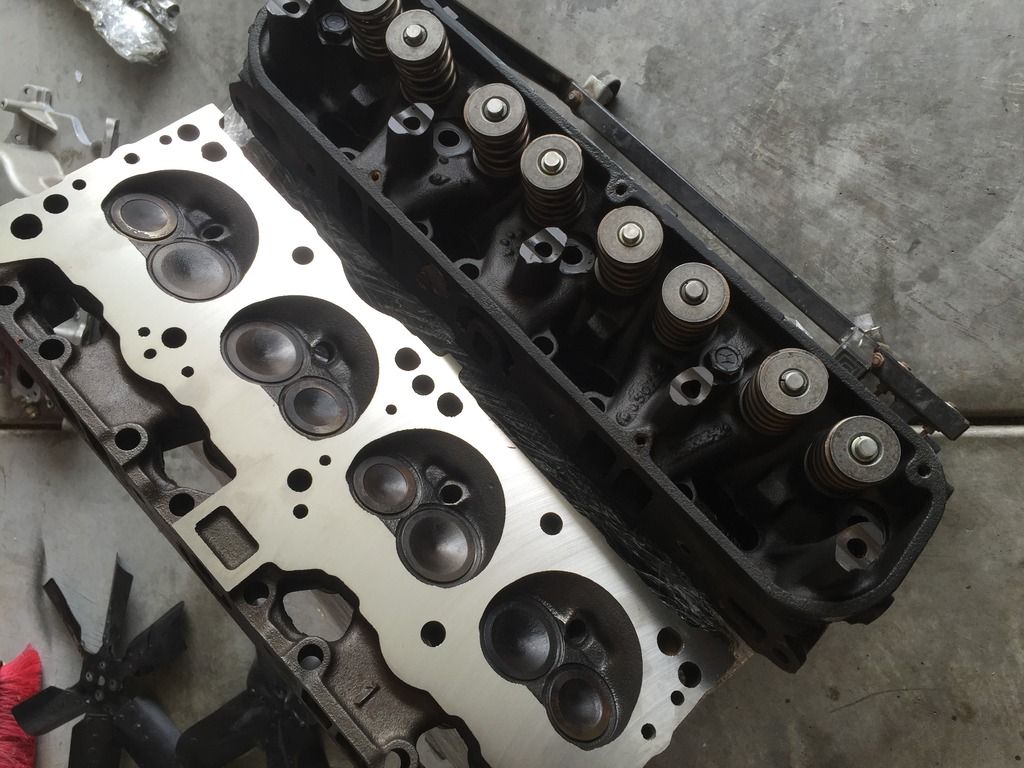

Timely thread. I just pulled my 273 heads and parts off the shelf and assembled them on the block for storage. I lightly oiled them, individually wrapped them in saran wrap and assembled with some used gaskets in between. Nothing torqued down just snugged up. Any other suggestions?

-